Finding Value in Building Enclosure Commissioning

Building enclosure commissioning is not a new concept, but the term is recently gaining ground in the design and construction communities. Industry standards and guidelines development and revision are on-going in an effort to lead project teams through the commissioning process, but the industry has yet to come to terms with its purpose, arrive at a consensus on the process and its implementation, or differentiate it from building enclosure consulting. This confusion leads to a process that is not fully leveraged. The building enclosure commissioning process, however, if implemented properly, can be very valuable: it improves quality, controls risk, and reduces costly changes and delays during construction.

As described in ASHRAE Guideline 0-2005 (The Commissioning Process), commissioning in general is “… a quality-focused process for enhancing the delivery of a project. The process focuses upon verifying and documenting that the facility and all of its systems and assemblies are planned, designed, installed, tested, operated, and maintained to meet the Owner’s Project Requirements.” It is a process envisioned to help the design and construction teams deliver a building that meets the owner’s goals and expectations for quality and performance.

As described in ASHRAE Guideline 0-2005 (The Commissioning Process), commissioning in general is “… a quality-focused process for enhancing the delivery of a project. The process focuses upon verifying and documenting that the facility and all of its systems and assemblies are planned, designed, installed, tested, operated, and maintained to meet the Owner’s Project Requirements.” It is a process envisioned to help the design and construction teams deliver a building that meets the owner’s goals and expectations for quality and performance.

ASTM E2813-12 (Standard Practice for Building Enclosure Commissioning) further defines building enclosure commissioning as a “… process that begins with the establishment of the Owner’s Project Requirements [OPR] and endeavors to ensure that the exterior enclosure and those elements intended to provide environmental separation within a building or structure meet or exceed the expectations of the Owner as identified in the OPR.” Simply stated, building enclosure commissioning is a commissioning process focused on the quality of the exterior building enclosure. Because commissioning has traditionally been a process undertaken for a building’s mechanical systems, many requirements in the building enclosure commissioning process are similar to those traditionally used for mechanical commissioning, with a few notable, but sometimes overlooked, exceptions.

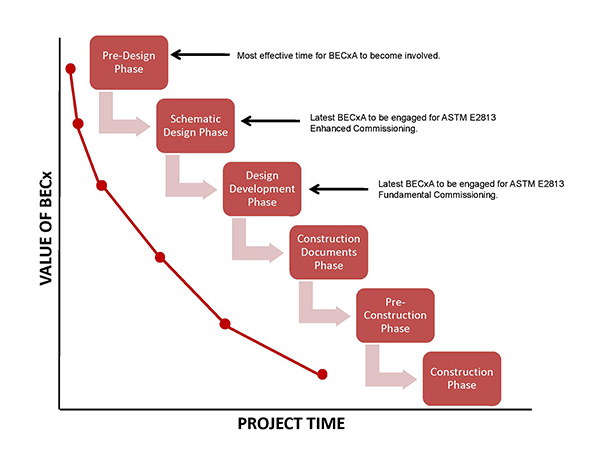

Determining how building enclosure commissioning can be most valuable on a project starts with an analysis of the building enclosure’s potential complexity, the amount of risk the owner is willing to undertake, and the relative roles and responsibilities of the various designers, consultants, and contractors that make up the design team. The real value in building enclosure commissioning is the reduction in risk of future enclosure performance issues by implementing a dedicated quality assurance process.

By definition, the building enclosure commissioning authority is an independent third party retained by the owner. Many projects will have a building enclosure consultant retained by the design and/or construction team. Although a consultant will add significant value to the team, the consultant’s role can vary substantially — it can be significant or minor in scope — and it may be limited to certain technical issues. A building enclosure commissioning authority provides the owner directly with broad, independent advice, helping to manage the owner’s risk and understand complex enclosure issues. The owner must vet the qualifications of their building enclosure commissioning authority to determine that they are competent and experienced in the design and construction of similar building enclosures.

The depth of involvement of the building enclosure commissioning authority in each of the project phases is not as important as the authority providing continuous review throughout the entire process. However, meaningful involvement requires qualified and experienced building enclosure commissioning authority staff. If implemented properly by qualified staff, the process will function as an exchange of knowledge, rather than production of checklists with no tangible benefit. If the building enclosure commissioning process is collaborative and inclusive, the authority will contribute to the project in a way that is valuable to the entire project team and will reduce the risk of future enclosure issues.

Related Topics: