Case Study: Optimize Energy Usage With Analytics Software

May 17, 2021

Wendel Companies provided energy services to a private university utilizing the Clockworks Analytics building analytics software. The Clockworks platform produces a daily list of the highest priority performance issues in a building. Each issue is summarized in a Diagnostic Report to recap the problem, provide probable cause, and prioritize each issue by avoidable cost and performance impacts.

The diagnostics will shine a light on where you should focus your time and resources to maintain your building at its peak. But to truly unlock the full potential of Clockworks you need a way to get this information into the hands of the people who can execute the work.

This case study summarizes how Wendel provided energy optimization services for a private university and helped them achieve $616,000 in annual energy savings by converting Clockworks’ diagnostics into 106 completed projects.

Wendel’s approach to energy optimization services starts by assigning a dedicated engineer to work directly with the university’s facilities management team. With Clockworks, this single engineer can analyze all 40 buildings on the campus and prioritize which diagnostics should be converted to internal work orders, contracted projects, or capital upgrades.

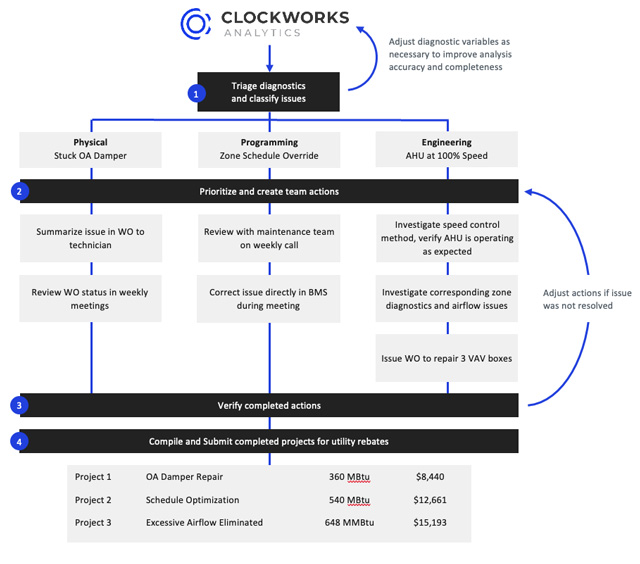

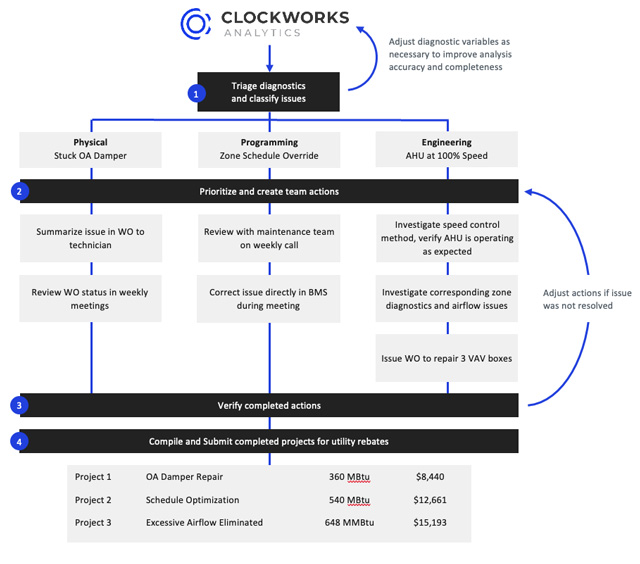

Wendel worked with the university to develop a unique 4-step approach to maximizing the impact of the Clockworks diagnostics:

Step 1: Triage Diagnostics and Classify Issues

The first step in the process is to review the type of issues being identified by the

Clockworks diagnostics:

• Physical issues are mechanical failures which could require new parts and repairs. In the example above, Clockworks has flagged a “Stuck Outside Air Damper” based on imbalanced airflows and/or damper position status not aligning with command. This is likely due to the damper being stuck or the actuator malfunctioning which would require repair/replacement.

• Programming issues are control failures based on the intended versus actual control strategies within the Building Management System (BMS). In the example above, Clockworks has flagged a Zone Schedule Override based on HVAC equipment operating outside of intended occupancy schedules. This can likely be corrected in the BMS programming by the facilities team.

• Engineering issues are complex system and equipment issues which require additional investigation. In the example above, Clockworks has flagged an AHU operating at 100 percent speed along with several zone airflow issues. Wendel classifies this as an Engineering issue requiring additional investigation.

Engineering issues can lead to larger capital or energy improvement projects.

Step 2: Prioritize and Create Team Actions

The second step in the process is to create the appropriate action(s) for each classified issue. Wendel’s dedicated engineer has access to the university’s work order system and engages with the team on a weekly basis to create the right task for the job.

Any ‘Engineering’ issues can be reviewed by the Wendel engineer prior to engaging with the facilities team to better understand the system impacts. In the example above, Wendel was able to confirm the AHU was operating as intended and examined the downstream zone diagnostics to identify VAV boxes not operating at their design airflows.

Step 3: Verify Completed Actions

The third step is to confirm the completed actions have resolved the underlying root cause of each issue. Since Clockworks is automatically collecting 5-minute interval data, this step can be completed by comparing pre and post operating data to validate the performance issues are resolved.

Step 4: Utility Rebates

The final step in Wendel’s process is often overlooked in typical deployments of Fault Detection and Diagnostics software. Many of the opportunities being identified by Clockworks can be submitted as Energy Conservation Measures (ECMs) to utility energy rebate programs. Wendel has capitalized on this opportunity by bundling all completed projects with supporting data and submitting to the local utility’s rebate program at the end of each year. This program provides rebates for any project saving electric and/or gas energy at a rate of $0.15/kWh and $0.9/CCF, respectively.

Wendel leverages the built-in energy calculations in Clockworks and supplements where required with custom engineering to maximize their client’s utility rebate.

The Results

Wendel began providing their Energy Optimization services to the university in late 2019. Over the course of just 14 months, they have guided the university through 106 completed projects resulting in $616,000 in annual energy savings.

They are actively tracking additional open and in-progress projects and continue to meet with the university’s facilities team weekly to find more opportunities to improve building performance. No matter how you measure return on investment, Wendel’s Energy Optimization service provided tremendous value to their university client.

Next

Read next on FacilitiesNet