for maintenance:

for maintenance:

Cardiologists often recommend that patients who have massive build-up of arterial blockage undergo a bypass or angioplasty to clear clogged arteries. But medical professionals are trained to probe deeper, examining a patient’s prior health history and running batteries of tests. In short, doctors seek the root cause of illnesses and physiological faults, hoping to prevent future health problems.

A similar process is at work in the Decisions Support for Operations and Maintenance (DSOM) program at the Pacific Northwest National Laboratory (PNNL), a diagnostic system that has reduced costs in various installations up to 33 percent. Software for institutional facilities is expected within 12 months.

“Our diagnostics look for the root-cause problems in operations with a perspective for life-cycle costs,” says Carl Imhoff, manager of energy products and operations for the DSOM program. “We’ve learned that diagnostic software helps in environments lacking the support of top-flight maintenance staff.”

Where it Started

The program started several years ago, when officials at the Twentynine Palms (Calif.) Marine Base experienced problems with a central heating plant.

“They were getting significant water hammer and other problems,” Imhoff says. “They asked PNNL for help because they thought they had to add a third boiler. The problems we saw there often are symptomatic of institutional environments, where O&M departments are traditionally at the bottom of the food chain with respect to budget and appropriate tools.”

So DSOM equipped the plant with sensors and diagnostic equipment that has saved Twentynine Palms an estimated $125,000 annually in component failures and $280,000 annually in natural-gas costs. The system also has added 30 percent capacity to the plant and enabled officials to defer anticipated capital construction costs in excess of $1 million.

How it Works

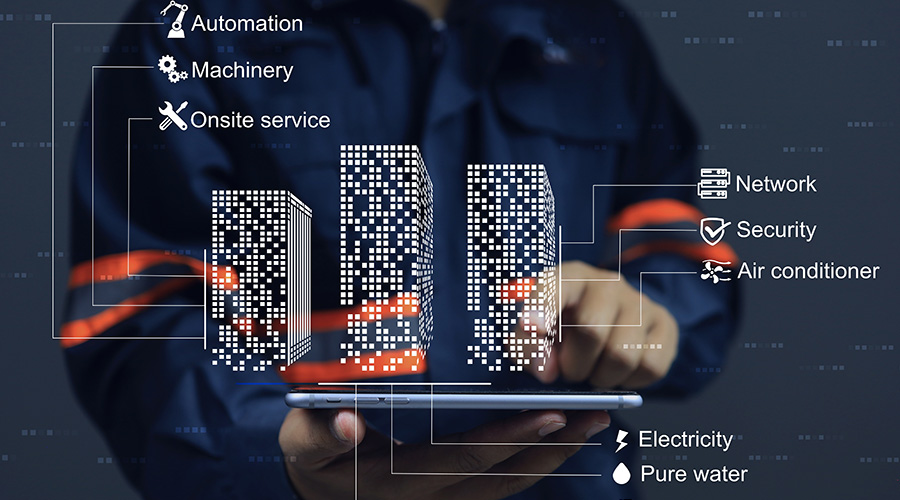

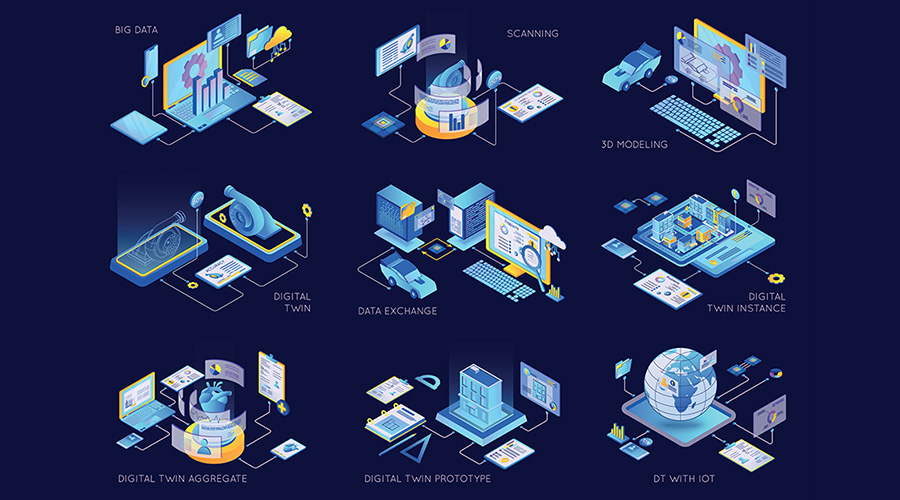

The system’s prognostics recognize sub-standard efficiencies and alert operators as to how to optimize operating conditions. Its condition-monitoring capability anticipates problems with components and signals any possible near-term failures.

Advances in sensors and diagnostics have made such gains possible, Imhoff says, as has intensive research. PNNL staffers run machinery to failure in the laboratory, introducing faults. They monitor stress levels, correlate them to degradation rates and predict performance. Using mathematical formulas, the PNNL researchers anticipate prognostic methods with greater accuracy than is currently available.

“We’re not using cutting-edge technology to do this, but we are using it for cutting-edge applications,” Imhoff says.

DSOM diagnostics are now used in a New York Housing Authority complex and several federal facilities, including a spent nuclear waste clean-up maintenance program at the Hanford (Wash.) site. The system also has expanded to address multiple building systems.

“A key driver for this is communication systems in facilities,” Imhoff says. “With good communications, it’s reasonable to expect three to five-year paybacks.”

Related Topics:

for maintenance:

for maintenance: