Once a standalone application, a CMMS must increasingly integrate with other applications in institutional and commercial facilities and share key data throughout organizations

Once a standalone application, a CMMS must increasingly integrate with other applications in institutional and commercial facilities and share key data throughout organizationsNew-Generation CMMS Options and Opportunities

Technology advances and greater flexibility result in software that can benefit departments and organizations.

As maintenance and engineering managers strive to streamline operations and make their departments more productive, they have a range of tools at their disposal. One tool in particular — computerized maintenance management systems (CMMS) can help them achieve these goals.

Critical components of management efficiency focus on clear concise and timely communication.

“The adage, ‘Time is money’ rings true as wasted time through slow or poor communication translates into huge sums of money being squandered as it flows through the operation, thus never reaching the end user — the facilities themselves” says Rebecca Smith, who is president and founder of WoofGang Solutions. The challenge for managers is to cost-effectively tap into the power of new-generation software in ways that benefit the department and the organization.

Technology evolves

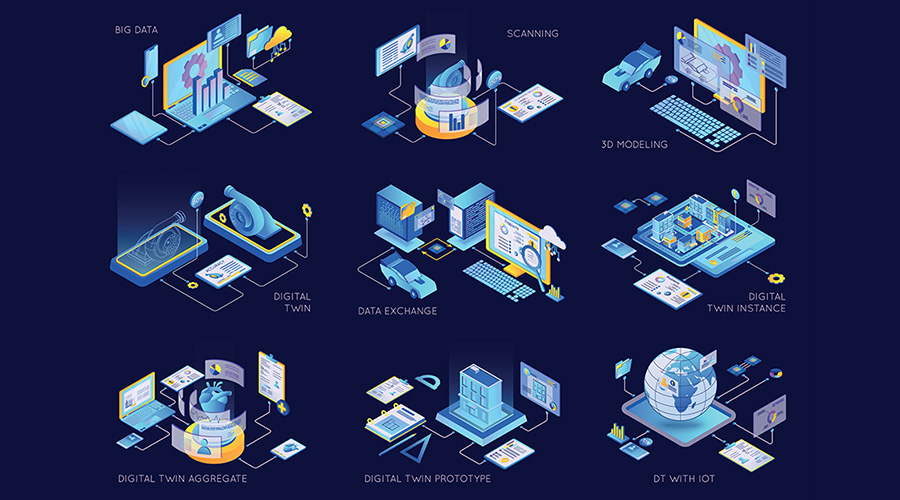

CMMS have come a long way in the last two decades. Once a standalone application, a CMMS increasingly must integrate with a host of other applications in institutional and commercial facilities and share key data throughout organizations.

“Currently, in the CMMS development market, keen focus is placed on data collection, data transfer and data retrieval with a demand for clear communication and efficiency,” Smith says. “As a result, user interface plays a key role. Point-and-click, drag-and-drop, along with at-a-glance data review, are fundamental to increasing the efficiency in the user functionality.”

While data collection is at the heart of many CMMS advances, other advances in recent years and on the horizon are designed to help give managers bring greater efficiency and productivity to their departments.

Three advances developers are integrating into CMMS are fault-detection systems, the Internet of Things (IoT), and augmented reality.

“Those are the big trends and advances that we are following closely and are starting to become integrated into products,” says Fred Tillman with Maintenance Connection.

Fault-detection systems include the addition of sensors to an array of maintenance equipment, most commonly HVAC equipment. These sensors are able to detect when equipment is going to fail and then help determine the best course of action in order to avoid the same failures in the future.

“The goal of fault-detection systems, which are primarily used on HVAC equipment, is first predictive analytics on maintenance devices and then prescriptive analytics on those devices — first predicting when maintenance might be needed on that equipment and then here is what you need to do in order to avoid those failures in the future.”

Going hand in hand with fault-detection systems is the Internet of Things. When sensors collect data from equipment, managers need a system that moves and stores the data so it is accessible later. The IoT is that bridge. The technology buildings connections not just between two devices in a system but among an array systems within a facility.

“The Internet of Things is closely related to fault-detection systems because all of that data that was collected needs to go somewhere to be analyzed, and that’s really where the Internet of Things comes in,” Tillman says. “Several companies are creating platforms to receive, manage and analyze these large amounts of data that are collected through sensors, either built into equipment or attached after market.”

The IoT can create opportunities for managers that include an increase in essential data, which can lead to greater efficiency, more effective maintenance and lower operating costs.

As maintenance and engineering managers continue their efforts to attract younger technician to the maintenance field, Tillman says augmented reality can help managers address that problem.

Augmented reality puts digital representations of objects into physical spaces and can change the way managers think about work. The technology can allow managers to connect with rare, specialized expertise instantly, no matter where they are located.

“Augmented reality opens up an avenue for training,” Tillman says. ”It opens up an avenue for assistance on how to do a repair before actually doing it by connecting with a more experienced technician in another office or by pulling up an instruction video. Augmented reality has a chance to truly help train and help capture some of this knowledge that we are losing as people retire and age out of the industry.”

Related Topics: