CMMS: 5 Questions on Integrating Data Into System

Part two of a three-part article on maintenance data and CMMS

While CMMS integration details vary depending on the manager’s requirements and the system used on a given project, managers need to consider a series of steps designed to ensure integration occurs more efficiently. A CMMS typically contains key building, system and equipment information.

The software enables managers, system administrators and planners to parse through the data and produce meaningful benefits for the department and the organization, such as work orders, inventory management, images, equipment information, and maintenance schedules.

The value of an implemented CMMS for maintenance departments is undeniable, but it can be difficult to get started with the implementation. If the goal is to use the CMMS for automatically generating preventive maintenance (PM) work orders, managers need answers to the following five questions to successfully move forward with data integration from new construction to the CMMS.

What information should the CMMS contain?

Understanding the information being targeted and the way it needs to be formatted for CMMS entry frames the rest of the integration process. Generating PM work orders requires two main information categories.

The first is basic equipment information, such as type, capacities, physical location, and warranty dates. This category can go beyond basic data to include barcodes and images. The second category is PM procedures and schedules.

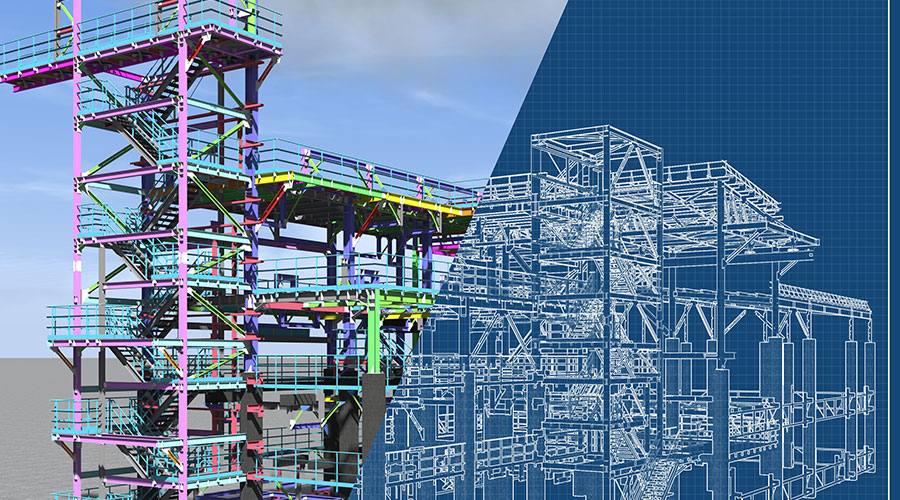

The CMMS dictates the format for data entry. In the worst case, this is laborious and time-consuming point-by-point data entry directly into the CMMS. The most common method involves spreadsheet entry, which can be streamlined if other software on the project can be used to produce a spreadsheet output easily formatted for the CMMS. In the best case, the department uses a CMMS that allows direct entry from BIM software already in use on the project by either the designer or construction manager.

Where do system administrators find information?

The information’s location varies depending on the data managers want the CMMS to store. The main locations for information are submittals, actual installations and other project-information software. Data submittals for equipment and products provide most capacity and characteristic information about the equipment and systems.

Operation and maintenance (O&M) manual submittals contain PM procedures and schedules. The actual installations often can provide information not found in a project’s paper submittals.

System administrators must be careful about accepting submittal information as fact because changes might have caused a different piece of equipment to be installed than the unit approved during submittal. It is important to back-check submittal data against the actual installation before entering it in the CMMS.

Finally, another information system, such as the BIM, already might contain needed information. The output from a BIM might even allow for a simple conversion to the CMMS entry method.

When is this information available?

The information to be entered in the CMMS will be available at various stages of a new construction project. Approved equipment submittals are available early in the construction phase. O&M manuals typically are submitted with project closeout documentation, but managers can and should request them earlier in the project.

Verifying equipment and associated data against actual installations should follow the construction schedule so that equipment and information do not become inaccessible. It is important to determine early in the construction process when information will be available so technicians can gather it at the appropriate time. Verification is best accomplished by asking the construction team on the project when specific information will be available and then following up with them as the critical dates approach.

Who has access to this information?

The information mentioned above usually resides with the contractors and should be available to the rest of the project team, including managers. But all of the information might not have been fully transferred from the contractors to the rest of the team. Whether or not this has occurred depends largely on the project managers and how well they manage the process.

Lost information is the largest bump in the road for CMMS integration because system administrators require at least three times the amount of time to research and locate the same information.

If the in-house maintenance and engineering team does not have direct access to this information, managers need a method to obtain it from the project team. This might require hiring a consultant for this phase of the process, or the scope for contractors or consultants already might include it.

How does the information transfer?

Once managers have answers to the earlier questions, the next step is to develop a protocol for collecting, assembling and entering the information into the CMMS. The earlier in a project that managers can answer these questions and develop a protocol, the smoother and more successful the process will be.

If answers to these questions come too late in the project, data collection and transfer will take substantially longer, and some of the information might not even be available. The largest part of developing the protocol is determining who will lead this process.

Related Topics: