Boost Efficiency: Predictive Maintenance Data Essentials

Predictive maintenance technologies and data management plans for maintenance managers to optimize equipment performance and integrate AI effectively.

By Dan Hounsell, Senior Editor

OTHER PARTS OF THIS ARTICLEPt. 1: This Page

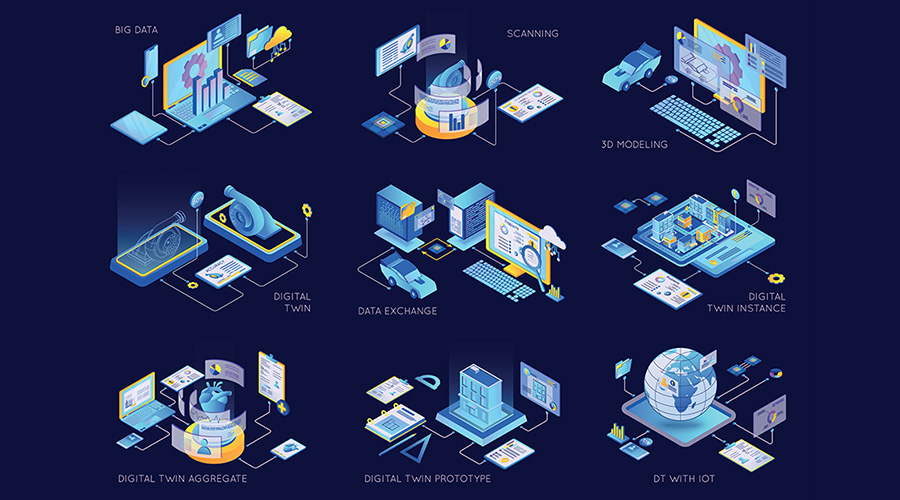

Predictive maintenance (PdM) technologies are critical for maintenance and engineering managers seeking to prolong the performance lives of key equipment and components, and the backbone of these technologies is data. The technologies capture valuable information on the condition and performance of key assets that managers and technicians can use to understand when and how they might begin to lose efficiency or break down. Planning for that process needs to start early.

“You need a data management plan up front,” Hodges says. “You need to know what data you’re going to collect and what you expect it's going to tell you about before you actually go out and take a thousand measurements because the thousand measurements could give you a thousand different points of reference that you do have no idea what to do with it unless you can pinpoint kind of what you're looking for.”

AI has become a buzzword among organizations looking to tap into its benefits related to data analytics, predictions and forecasting, but Rimer says managers need to proceed carefully when considering implementing the technology.

“Managers say, ‘I need to do that,’” he says. “I agree that you do need to move forward to where ideally, you're getting to condition-based maintenance. But you're so busy firefighting, and you don't have the manpower, you don't have the bandwidth, and you can't even see the forest for the trees cause the trees are on fire.”

Only after PdM technologies have begun gathering essential data can managers begin to analyze it and begin to consider AI. The technology analyzes the data based on different variables and algorithms and alerts the department’s CMMS that, for example, a sensor is out of calibration. That alert creates a work order that tells the technician that they need to check the sensor and calibrate it or possibly replace it.

“That is ideally where we need to get,” Rimer says. “That starts increasing the efficiency and utilization of those limited wrench turners so that when they get that work order, they know this analysis has been done.”

Putting it all together

Perhaps the toughest challenge managers face in incorporating PdM technologies to benefit their departments and facilities is building a solid foundation that enables the technologies to deliver their potential benefits. The pressure to speed up this process can be immense.

“They try jumping into the deep end when they don't know how to swim,” Rimer says, adding that executives too often learn about AI and other related technologies and push managers to implement them. “They hear of this new technology at a conference or in a journal and decide they need to do this. But they're not ready for it.

“That is a big mistake. It's just that disconnect and not having the appropriate building blocks in place. You need to set that vision of where you want to go, but then you have to build a plan and work the plan. You just can't jump to the end.”

Building the plan means addressing the needs and interests of a range of affected parties within the organization.

“Make sure you're bringing your team along with you,” Rimer says. “That includes all the way down to the boots in the field, maybe even your contractors. Lean on their expertise. Make sure they understand where you're going. Tell them, ‘I’m not trying to work you out of a job. I'm trying to make it so that you can do your job better.’ As they get that, they'll help identify opportunities to make the overall program more successful.”

Hodges reminds managers that PdM technologies will not replace preventive technologies and practices.

“I don't think that's ever going to replace preventive maintenance,” he says. “To me, a good facility management maintenance strategy encompasses all those things — preventive, corrective, predictive. It applies predictive maintenance technologies where you have the data or where you want to use the specific techniques to evaluate the performance of a specific piece of equipment that you can’t tear apart. You can use some of these methodologies to help you understand it.”

Dan Hounsell is senior editor for the facilities market. He has more than 30 years of experience writing about facilities maintenance, engineering and management.

Related Topics: