3 Steps to Implementing a CMMS

Here are steps managers can take to properly implement a CMMS.

Updating to an automated inventory management system is not as simple as buying the right software. In fact, over the life of the system, the cost of the software is almost insignificant. The real costs come from gathering and entering the data that the system uses. Data drives the system and makes inventory management possible.

Managers can start by standardizing the inventory processes, including the way they purchase items and add them to inventory and the way technicians draw them from inventory. If technicians return items to inventory, either because the wrong item was drawn or too many of the correct item were drawn, they must follow a standard process so the data is entered into the system each time correctly. If items are charged to a specific project, managers need to set up a system that technicians can readily follow for all projects. It is essential that managers have a process in place to capture all inventory events and transactions.

Next, managers need to complete an inventory of all replacement parts, materials and tools already in stock, assigning each item in stock a unique item number. For each item, they need to record a basic description, vendor source, location in storage, and other relevant information.

They also need to perform an initial count of items in stock. If this is the first inventory or if the number of items in inventory is large, start with the high-use items first. Even if managers can transfer data from another system, it is important that they complete the initial inventory to make certain the count is accurate.

Reaping rewards

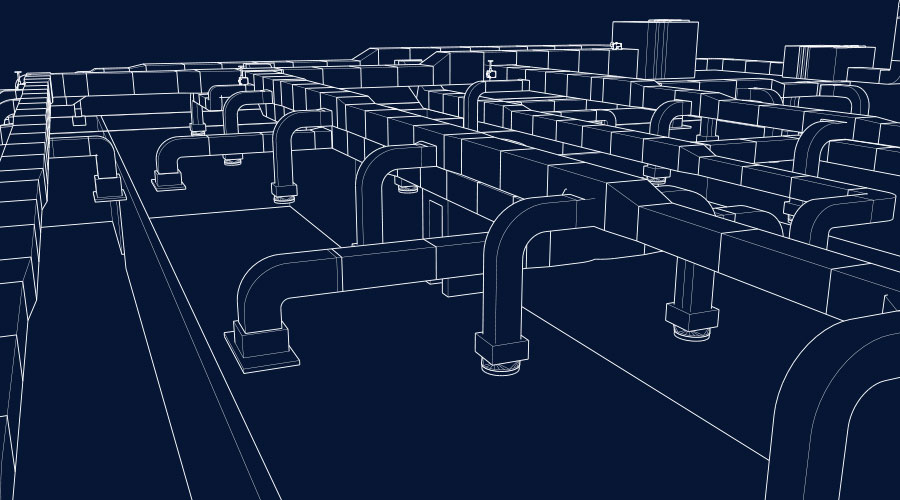

An inventory management system offers the promise of better warehouse inventory organization, fewer delays when technicians draw parts from inventory, and reduced costs in maintaining essential parts in inventory; all benefits that help increase system efficiency and productivity.

A great deal of work goes into setting up a system, but once set up, the payoff can be immediate. As the system develops an operating history, managers must pay attention to the information that the system is generating. This is where many of the additional rewards of the system will be realized.

One of the most important reports that the system can generate is stock movement. When the system was set up, estimates were made of how many of each item should be kept in stock; the minimum reorder point. Look at the track record for use. Were the assumptions made concerning use and reorder points accurate, or do they need to be revised? When during the year did the use occur? Is the system stocking too many or too few of the item?

Look for items that haven’t been used at all over a set time period, typically one year. Review each of these items to see if they really need to be stocked. In some cases, the lack of use could be the result of timing; the maintenance tasks that would require those items did not have to be performed. But in other cases, lack of use could indicate that the item is obsolete, replaced by a different one or that the equipment that used this part was removed from service and no longer exists. It is these orphaned parts that unnecessarily take up space in the inventory system and can be disposed of.

Related Topics: