CMMS Specification Solutions

Managers whose departments use only a fraction of a CMMS's available features did not specify the most appropriate software. It means the application has many bells and whistles the department does not need. The incorrect selection decision costs the company money on the software's acquisition, as well as user training — money the manager could have saved by specifying the most appropriate package based on department needs.

Whether you are upgrading to a newer version of the CMMS or acquiring a new CMMS, selecting the right package is crucial to a successful implementation and enabling the department to fully use the CMMS's features and functions. Managers should consider answer these specification questions:

Is it easy to use and flexible? The CMMS should be designed for front-line maintenance technicians, not computer experts. The system has to be flexible enough to accommodate the way they carry out their daily tasks, not the other way around.

Does it handle queries and reporting effectively? These are two very important functions of a CMMS. Once the implementation is complete, users each day retrieve the desired information and generate reports to help managers make more informed decisions. Managers should be able to retrieve any information required, when they need it and in the desired format.

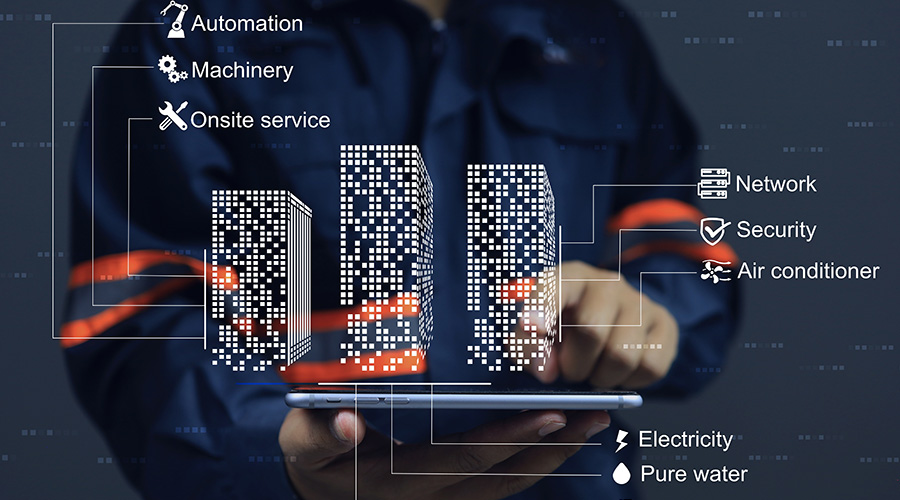

Does it improve workflow? An efficient flow of work — initiating and approving a work request, planning, scheduling, dispatching, completing it, and following up for continuous improvement — is essential for productivity. A CMMS's work-request system enhances the efficiency of the maintenance operation, as well as the requester's productivity. Requesters must have convenient access to the status of open and completed work requests, which prevents dips in productivity by helping them identify and dispose of duplicate requests.

Enabling customers to enter and view their work requests increases efficiency for both the requester and the maintenance department by substantially reducing the number of repeated requests to perform these functions. Repeated calls are a significant drain on productivity, not only due to the time they consume but also because of the unplanned interruption of work by the technician.

Does it provide a satisfactory parts list? A CMMS should have a provision for specifying parts and tools on PM work orders so technicians can arrive on the job site prepared with required parts, resulting in less downtime.

Related Topics: