CMMS Help Managers Tackle Productivity, Budget Challenges

Accountability. Efficiency. Accuracy. Those three words represent goals every maintenance and engineering department strives for in carrying out daily tasks and planning for short- and long-term projects.

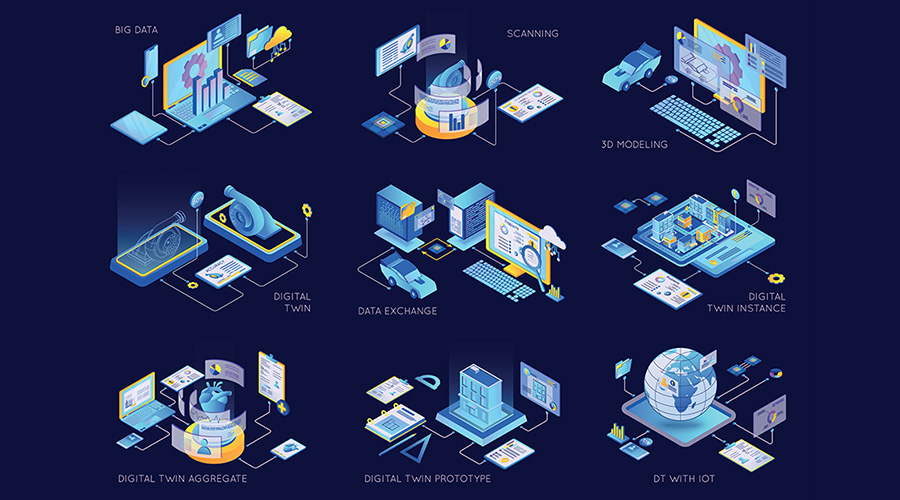

Computerized maintenance management systems (CMMS) are among the most powerful tools managers have for achieving those goals. These complex systems are engineered to streamline maintenance and operations activities and offer a roadmap for the way departments conduct business.

"Our entire department is dependent on our CMMS system," says Walt Petters, director of maintenance and plant operations with Brevard County Public Schools in Rockledge, Fla. "It's how our customers communicate a need. It's how we document our repairs, and it's how we validate our time and effort."

In a difficult economic climate, more managers are specifying or upgrading a CMMS to neutralize the negative impact budget challenges can have on department efficiency and productivity. But are managers maximizing the potential of CMMS? The consensus is many departments use a CMMS to manage basic functions, such as work orders, but do not employ the system's more complex capabilities.

Organizations often underuse a handful of key CMMS functions. To realize the lasting impact a CMMS can have on departments, managers should delve further into the systems' capabilities.

Related Topics: