SPONSORED

Filtration Group Corp - Branded Feature

How A HVAC Total Cost Of Ownership Analysis Saves Money

hvac.filtrationgroup.com

By Michael Bruce

Today, facilities with HVAC systems must work to keep them as reliable and optimized as possible. Facility managers and decision-makers are tasked with determining price vs. value, comparing wide ranges of filters, and are often required to be experts when considering Total Cost of Ownership (TCO). Given the many variables and moving parts, including the costs of labor, energy and disposal – it’s a lot to ask.

A Crucial First Step

HVAC operations – like most – do not operate in compartmentalized vacuums. Every component and decision has an effect on the operation as a whole. To stay competitive, successful managers understand that they need to look at their systems holistically – simply comparing Price A to Price B will only result in a myopic view.

Increasingly, facility operators understand that working with filtration experts who provide TCO analyses will ensure that their system is functioning as efficiently as possible while protecting the bottom line. This comprehensive approach is the crucial first step to optimization and will ensure pragmatic purchase decisions.

Primary cost considerations in a TCO analysis include:

- Filter purchase price and lifespan

- Installation Labor

- Energy consumption

- Repairs

- Maintenance

- Disposal

When properly collated and summarized by the filtration expert, these factors help to inform the best balance of TCO and Indoor Air Quality (IAQ) requirements for the application. All applications have different contaminant conditions and energy, labor, disposal, and shipping rates vary from location to location. This makes a customized analysis better than a one-size- fits-all solution.

A concern, however, is when facility operators assume their systems are optimized forever. It is important to maintain ongoing TCO practices to stay informed and cognizant of even minimal changes in labor, energy, disposal costs, etc. Of equal importance is the discipline of changeout schedules – the incremental energy consumption of a filter at end-of life often surpasses the cost of a new filter very quickly.

Key Questions

Once the decision is made to work with a filtration expert, a number of key questions will help you to better navigate the process.

- Do you know the optimal changeout schedule for your filters?

- Are you able to recognize when a prefilter is needed and when it is not?

- Do you know the benefits of a higher MERV prefilter?

- Do you know the cost of a higher MERV filter?

- When did you last have a complete Air Filter Audit?

By working with a filtration solution expert, you can not only answer these questions with complete confidence, but you can also dive deeper and potentially discover additional ways to optimize your system.

Sometimes, a simple move from a MERV 8 to a MERV 10 filter will result in substantial cost savings and improve downstream filter life. Additionally, certain scenarios can benefit from filters with large amounts of media for increased dust-holding capacities. In this instance, a prefilter isn’t necessarily required, yet managers without a grasp of their TCO will often use them anyway.

Table 1

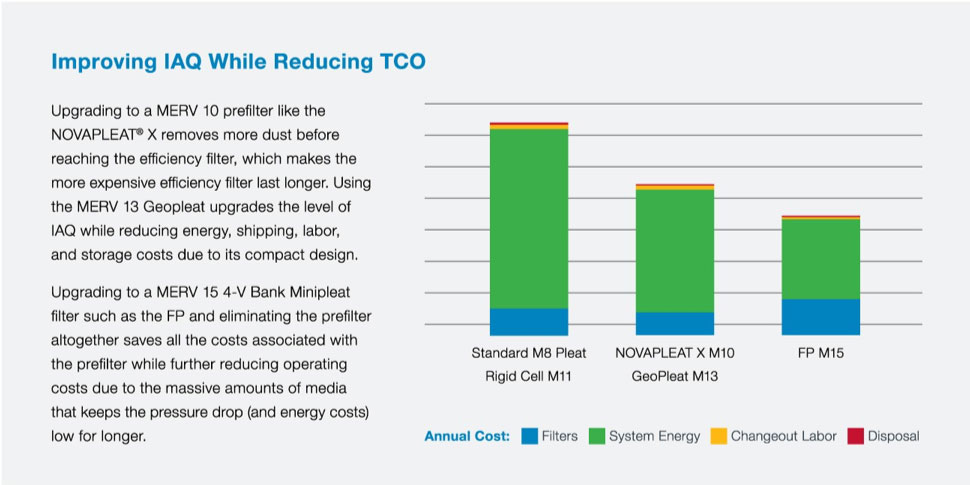

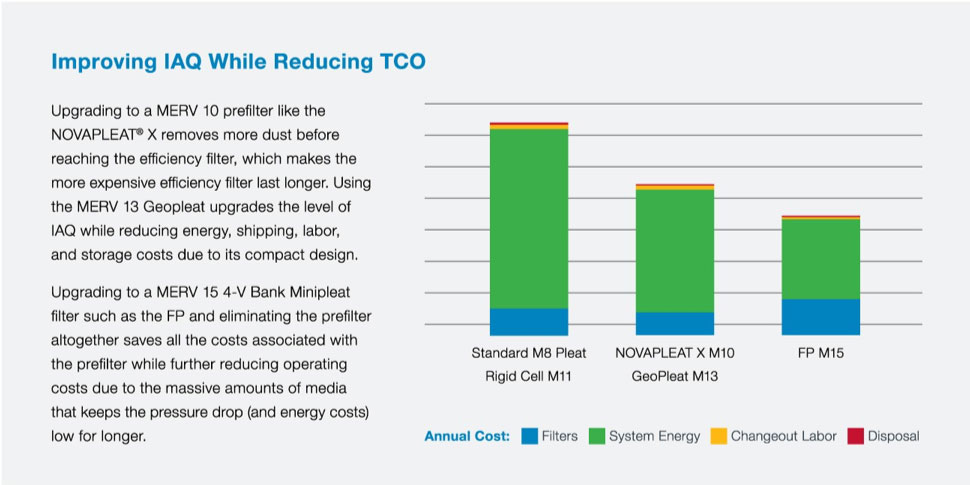

Table 1 demonstrates an example of two ways to improve TCO while filtering at a higher MERV, thus improving IAQ. Commercial and Industrial applications that use legacy products including standard capacity MERV 8 pleats and MERV 11 Rigid Cell efficiency filters are ripe for an upgrade.

Cost vs. Value

Years of research and development have yielded products that do a great job of achieving required filtration efficiencies while delivering a much lower TCO. Ultimately, products and services that deliver overall value are the keys to monetizing your HVAC performance.

The four products shown below combine innovative technology and precision materials with demonstrated efficiency ratings that help facility managers take command of their total costs.

- The ENDURO-PLEAT is a tough filter that saves time and money in all applications. It is constructed with stronger components for longer service life and reduces energy consumption due to a low pressure drop and high dust holding capacity. Switching to ENDURO-PLEAT is the most common way to save on HVAC filter TCO.

Aerostar® ENDURO-PLEAT® High Capacity Heavy Duty Wireback Pleated Air Filter

- The Geopleat filter is a leading compact efficiency filter with a large amount of media. It guarantees a long lifespan and requires less space, while filtering at a high MERV. It saves on shipping and storage costs due to its compact design – making it efficient in multiple ways.

Aerostar® GEOPLEAT® Mini-Pleat Filter

- The FP 4V-Bank Minipleat provides efficient media and industry-first design resulting in High Dust Holding Capacity for long life. This filter consumes less energy due to its low pressure drop, often saves all the costs associated with a prefilter, and provides the best savings when considering TCO.

Aerostar® FP 4V-Bank Mini-Pleat Filter

- The recently launched FP Dual-Pak 4V-Bank Minipleat does the work of two filters in one, like the standard FP. It performs a broad spectrum of gas phase and particulate filtration with a much lower pressure drop when compared to separate MERV 15 and gas-phase filters. This reduces TCO for applications that need this level of filtration, while becoming affordable to applications that don’t need it, but could benefit from it.

Aerostar® FP Dual-Pak 4V-Bank Mini-Pleat Filter

Making Informed Decisions

A comprehensive TCO analysis will help you understand long-term value compared to upfront costs. This information will prove to be the key to optimizing your system. There are circumstances when a filtration solution may be the lowest price, yet most applications save money with higher-performing, albeit more expensive, filters. The mistake however, is making an assumption. More filters don’t always equate to better filtration, changeout schedules vary, and sometimes prefilters make a positive financial impact and sometimes they don’t. The more informed you are regarding your facilities’ costs, usage, and operations the better positioned you will be to stay competitive. A quality filtration expert and a TCO analysis will help you make that step.

Michael Bruce is the Director of Marketing and Customer Care for Filtration Group, HVAC. As part of the world’s fastest growing filtration company, he oversees product management for the HVAC division. He has three granted patents. Previously, he held roles in sales, operations, and engineering in various industries. Michael graduated Magna Cum Laude from the University of Maryland, Baltimore County, with a bachelor’s degree in Engineering.