SPONSORED

Panametrics - Branded Feature

District energy efficiency through flow metering

As energy costs rise, energy efficiency becomes increasingly important. This has been recognized in both public and private sectors. Energy efficiency affects all aspects of our lives and no more so than in the building environment. Forty percent of energy consumption and carbon emissions in Europe and the United States comes from the way our buildings are lit, cooled and heated. Even comparatively small changes in energy performance and the way we use each building will have a significant effect in reducing total energy consumption.

This paper looks at energy efficiency and how energy monitoring through flow metering can help to achieve energy saving targets and enable various tenants within building complexes to pay a fair price for the energy they consume.

Introduction

The path to energy efficiency in buildings includes many steps. It is important that buildings are designed to conserve energy, in terms of the materials used and the insulation provided, to preserve the energy supplied to the building. It is important that the lights within a building are used intelligently to maximize the use of natural daylight and to ensure that they are switched on only when required. It is important that any plant and machinery used in heating, cooling and air conditioning operate effectively and are serviced regularly to optimize efficiency.

Energy management

The key to energy efficiency is management. It really doesn’t matter how much you spend on the building envelope and the latest energy-efficient equipment—without management, you will waste energy—and money.

Lord Kelvin made many pronouncements in his lifetime and one of his most famous attributable quotes was, “If you can’t measure it, you can’t improve it.” This becomes the key maxim of energy management. You can’t manage what you can’t measure. This remains true even if the building is a single house. It is especially true if the building is part of a large building complex, such as a university campus, a corporate headquarters, a large school, an airport or a military installation. The same philosophy applies, and the measurement problems increase as the building complex size grows. For example, a single building would probably have a very simple heating, cooling and air conditioning system. Heating could be electric or provided by a boiler producing hot water to be circulated around radiators. Air conditioning would be a separate system, relying on a basic refrigeration circuit.

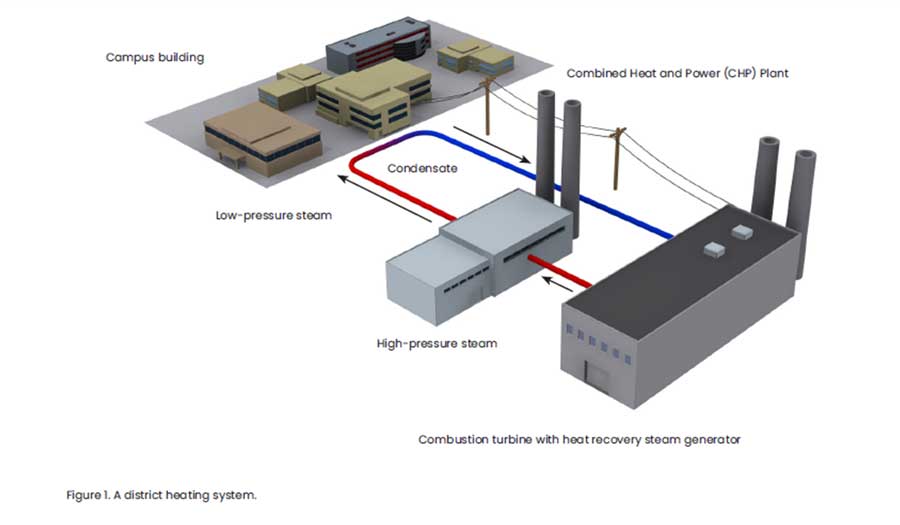

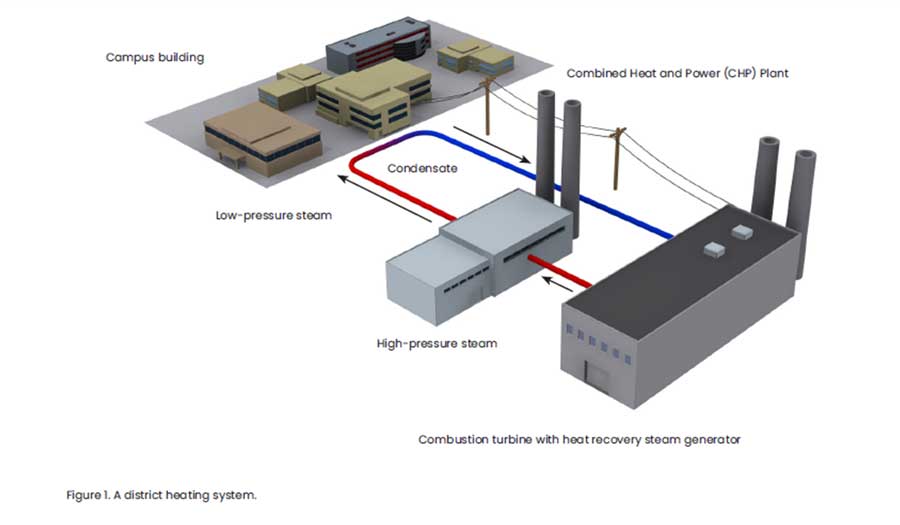

However, with a building complex, heating and cooling requirements are mostly met through a central system, or district energy system. District energy systems produce hot water, steam or chilled water at an energy efficient central plant for distribution throughout the complex. As long as proper insulation of pipework exists, this is much more energy efficient than heating and cooling sources in each individual building—but it does offer more difficult measuring and monitoring challenges. Multiple ownership of buildings within a complex makes these challenges more complicated as it will be necessary to measure the amount of heat used by each building for billing purposes.

Very large building complexes sometimes meet their heating requirements with Combined Heat and Power (CHP) plants, where the waste heat of power generation is captured. In most electricity generating plants, over half of the energy of the primary fuel is wasted as excess heat. By capturing this waste heat, the efficiency of power plants can potentially reach up to 89%, as compared to around 55%, providing both financial and environmental benefits.

No matter what the primary heating or cooling source, various parameters need to be measured and monitored to enable efficient heating and cooling performance and to provide accurate individual billing. Among those parameters most important in deciding energy distribution efficiency are flow and temperature, as they are used to calculate the heat or energy delivered to or removed from a building.

Flow metering

There are many types of flow meters, both for water and for steam. This can make the correct selection of a flow technology a difficult task, as each offers different benefits and disadvantages.

Accuracy should be a prime consideration, but there are other features that could affect the final selection. For example, is the water or steam pressure affected by a pressure drop through the flow meter, requiring increased pump pressure that results in increased cost? Is the meter easy to install and inexpensive to maintain? Can it handle a wide range of flows? Can it be integrated with the building complex energy management system? Does the meter have moving parts that wear out over time, causing drift and decreased accuracy? Can it provide true energy consumption details? Does it need calibration? And finally, what are its capital and operating costs?

To answer these questions, we can review some meters commonly used for district energy flow measurement.

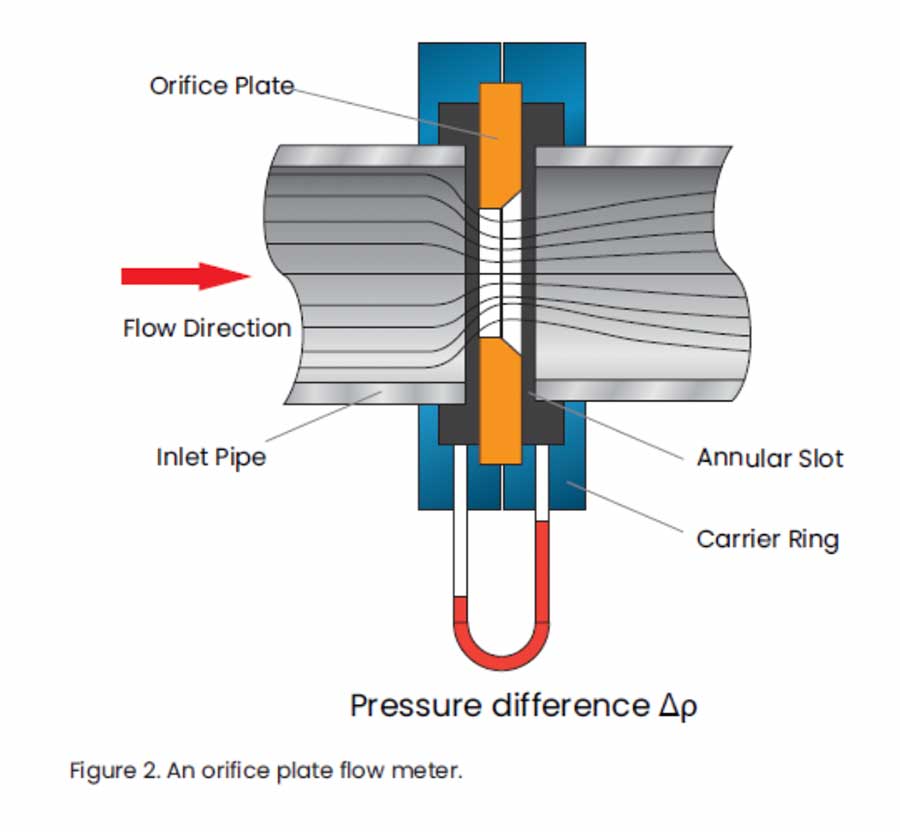

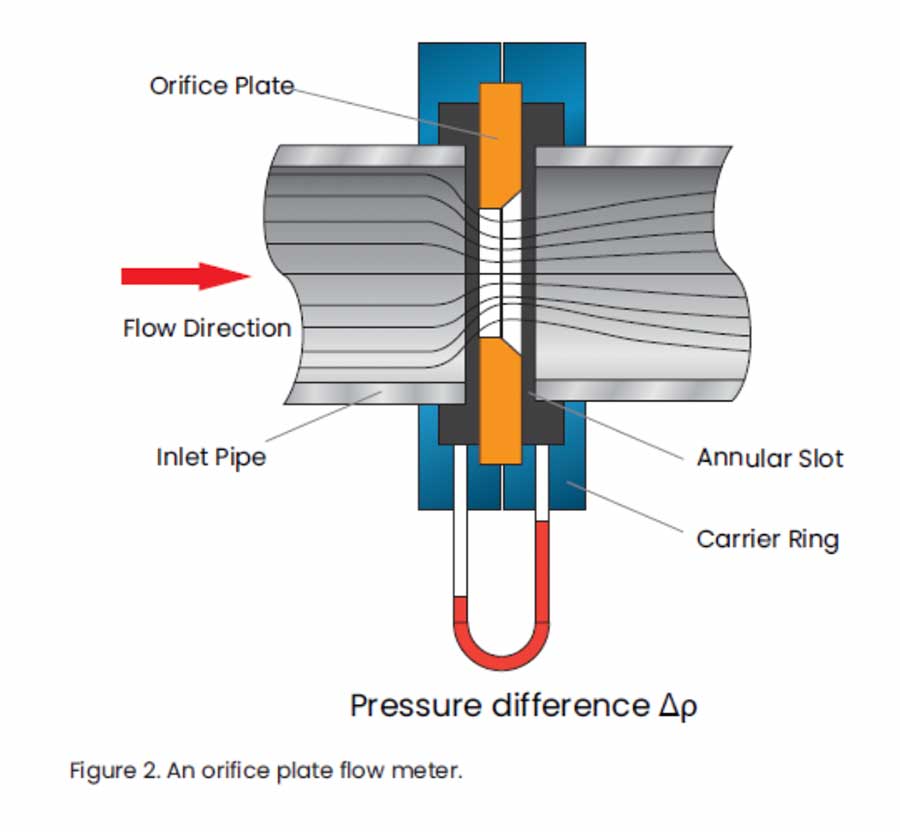

Orifice plate flow meters

Orifice plate flow meters use the same principle as a Venturi nozzle, where the differential pressure across the orifice is proportional to the square of the fluid velocity. This fluid flow can be given in volumetric or mass flow rate depending on the calculation applied. Orifice plates are simple, rugged, reliable and inexpensive and have no moving parts. However, they are only moderately accurate and the pressure drop requires increased pump pressure that contributes to energy loss. The orifice plate itself can erode with use causing drift in accuracy. These flow meters also cannot handle a wide range of flows, which is expressed as a low turndown, meaning that there is a ratio of just 10:1 between the maximum and minimum flow rates.

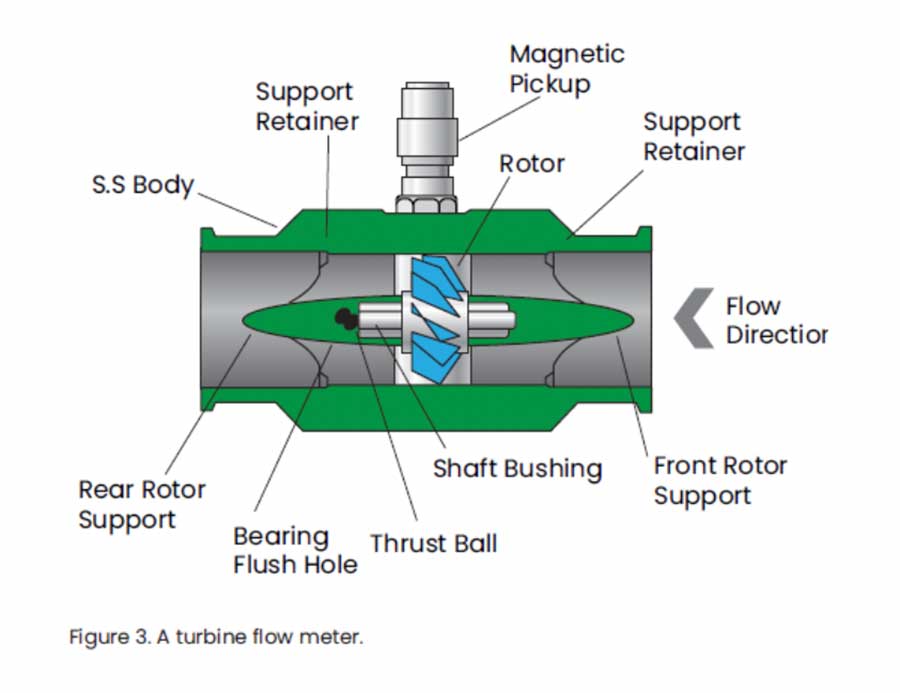

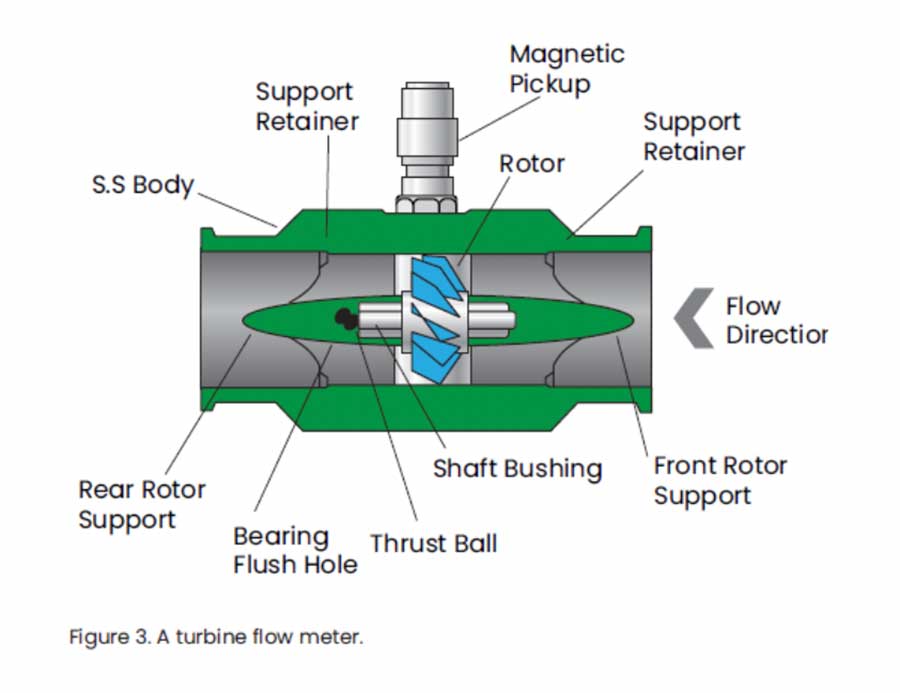

Turbine flow meters

These are mechanical devices, measuring flow from the action of the flow on a movable component. Most widely used are turbine meters, where the linear velocity of the fluid stream rotates a primary impeller element. Like orifice plates, turbine meters are inserted in the flow and this obstruction creates a pressure drop that produces an energy loss. The rotors on a turbine meter will require maintenance and likely replacement after periodic use.

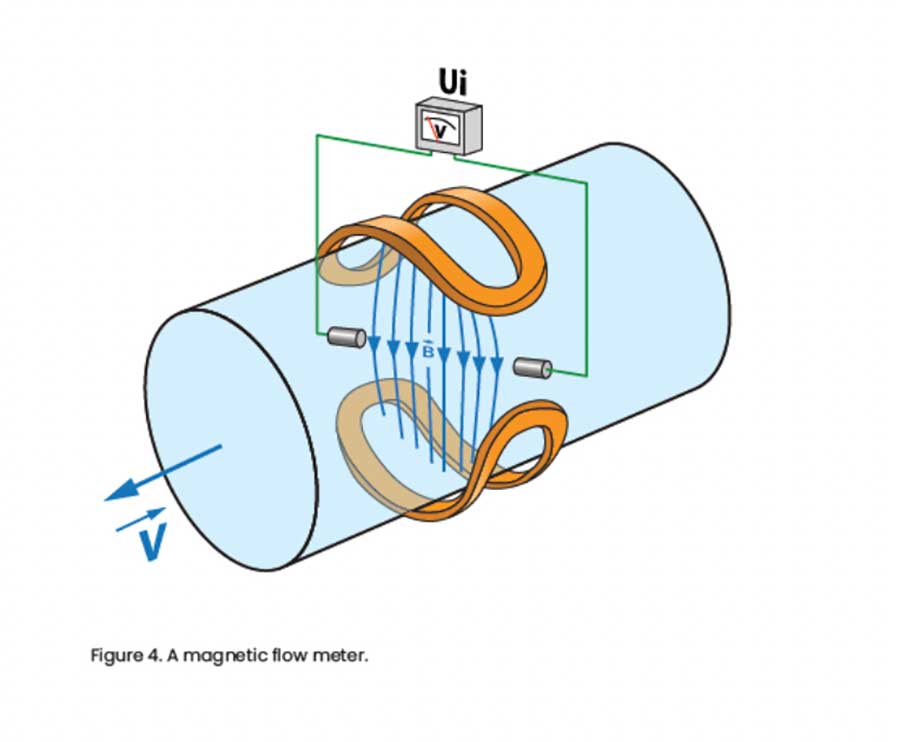

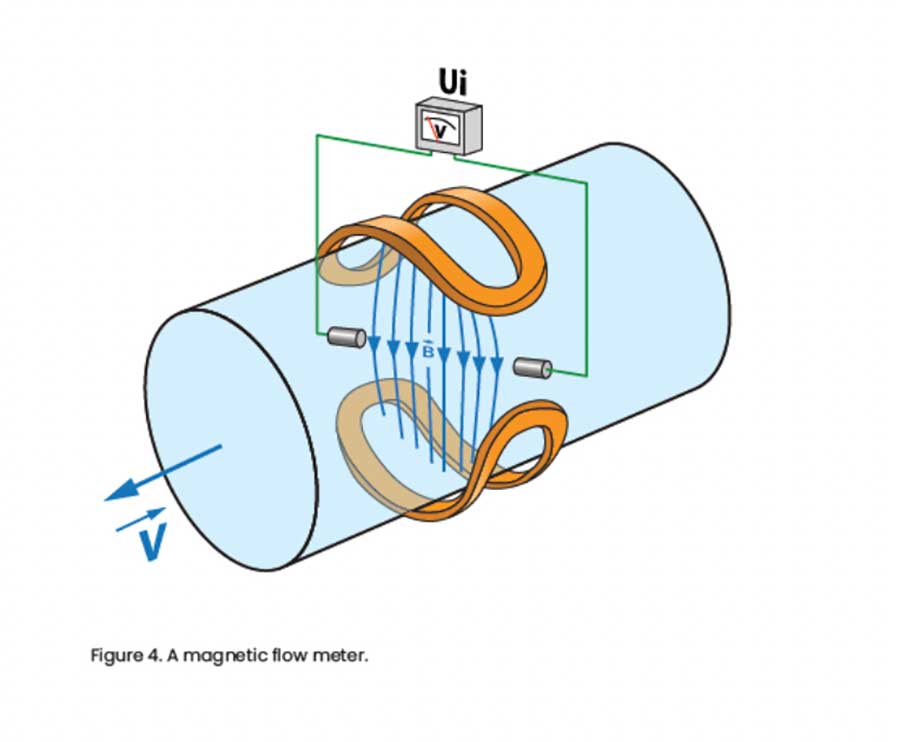

Magnetic flow meters

Magnetic flow meters are used for measuring water flow, but cannot measure compressible fluids. They rely on Faraday’s second law of electromagnetic induction. Mag meters create a magnetic field in a conductive liquid, and the flow of the liquid through this field produces a voltage signal sensed by electrodes located on the pipe walls. The voltage generated is proportional to the movement of the flowing liquid, according to the equation:

Voltage = B x v x d, where B is the magnetic flux density, v is the velocity of the fluid and d is the diameter of the pipe.

Advantages of magnetic flow meters include a typical accuracy of +/- 0.3% of reading and also that they do not create a pressure drop. However, they can be subject to erosion and scale build-up. Installation on existing pipes can be difficult and time consuming, involving shutting down the process, draining the line, cutting the pipe and welding on flanges.

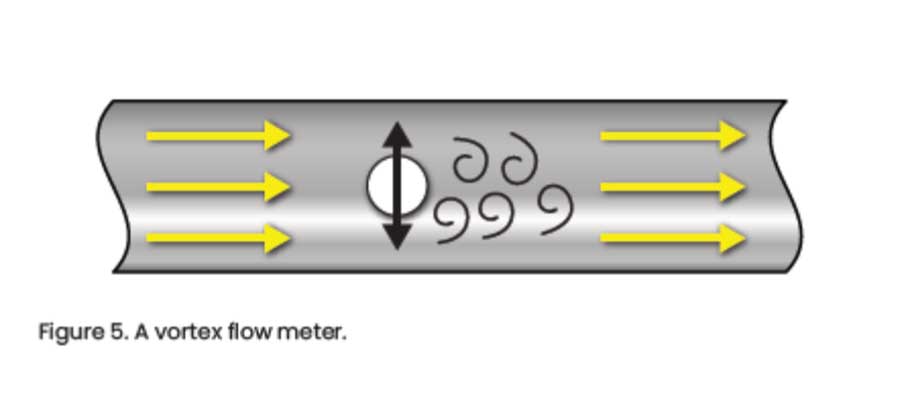

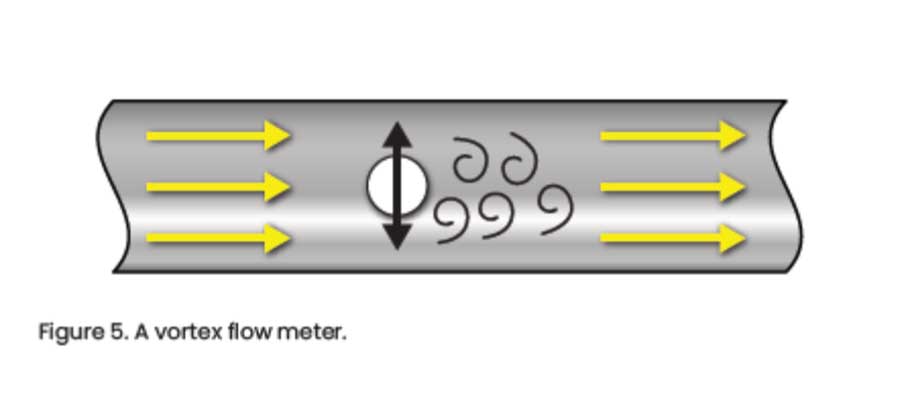

Vortex flow meters

Vortex meters measure flow rate by measuring the frequency of vortices shed off a bluff body located in the flow stream. The frequency of vortex shedding is measured by a piezoelectric crystal, which produces a small voltage pulse every time a vortex is created. The frequency of occurrence of these pulses is proportional to the fluid velocity.

Vortex meters offer a cost-effective, accurate and reliable measurement for volumetric and mass flow of water and steam. They do not need re-calibration and can offer a volumetric flow rate repeatability of +/-0.1% of rate and a mass flow rate repeatability of +/-0.2% of rate. The bluff body used to create the vortices naturally creates a slight pressure drop that may increase energy usage, but installation is relatively simple.

A major advantage of vortex meters, such as the multivariable MV80 and MV82 from Baker Hughes, is that they can also provide direct energy usage measurement because they incorporate an integrated resistance temperature detector (RTD) to measure temperature. This can then be combined with the flow rate and the pipe area to provide a basis for calculation of the energy rate in BTU/hr, KJ/hr, calories/hr or other selectable energy units. The MV80 and MV82 meters also feature a built-in pressure transducer to offer better energy usage calculations for steam. Integration with even the most sophisticated of energy management systems is possible by means of HART® or Modbus communication protocols and in addition to outputs for totalized mass and alarm settings, the field-configurable electronics deliver up to three analog 4-20 mA outputs of five process measurements. With a turndown of more than 100:1, dependent on application, these vortex meters can handle a very wide range of flows. This is important in a building complex, especially for steam where flow rates vary considerably between seasons.

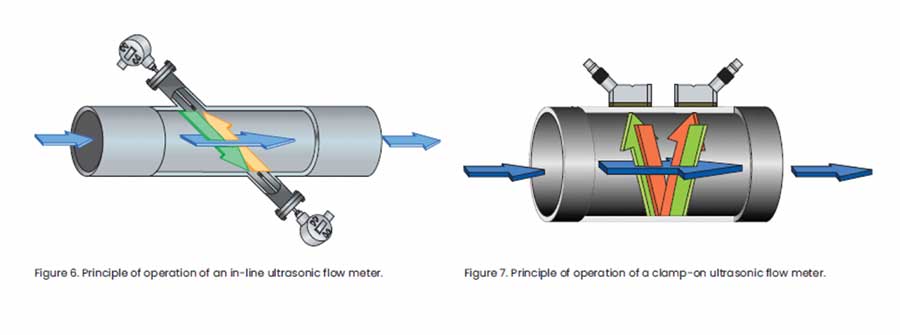

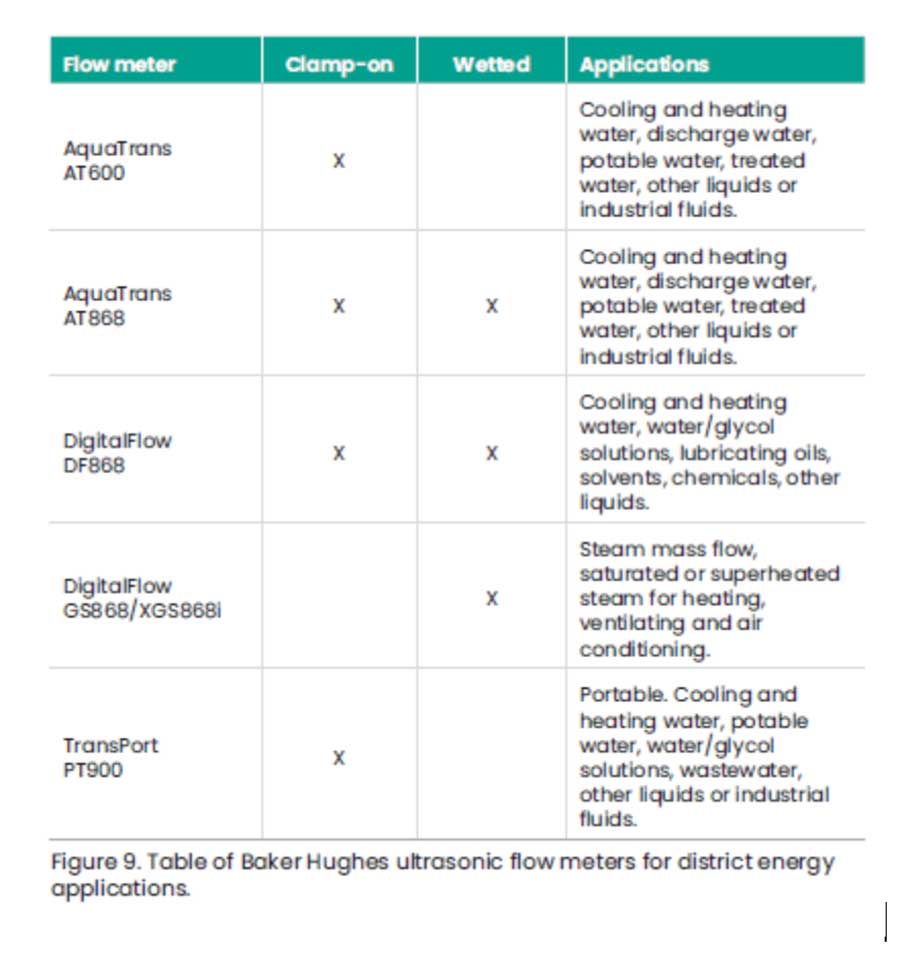

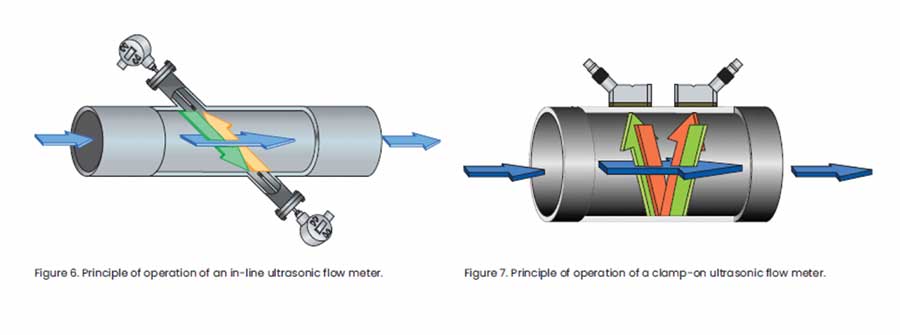

Ultrasonic flow meters

Although ultrasonic flow metering is thought of as a relatively new technology, ultrasonic flow meters have been used for liquid flow measurement for more than 40 years. Ultrasonic flow meters using the transit time flow measurement technique are the most common. This measurement has ultrasonic transducers installed in or on the pipe, one upstream of the other. The meter measures the time of flight difference between an ultrasonic pulse sent from one transducer in the flow direction and an ultrasonic pulse sent from the other transducer opposite to the direction of flow. Both transducers operate in transmit and receive mode. The difference between these two times is a measure of the average velocity of the fluid along the pipe and is calculated by signal processing technology. By multiplying the calculated velocity by the pipe cross-sectional area at the measurement point, the volumetric flow is obtained. Mass flow is obtained by multiplying this figure by the fluid density.

There are two types of ultrasonic flow meter: in-line and clamp-on. With in-line flow meters (Figure 6), the transducers can be installed in a flow cell or spool piece inserted into the pipe or they can be located directly inside the pipe. Clamp-on meters, as the name suggests, simply clamp onto the outside of the pipe (Figure 7).

Ultrasonic flow meters have no moving parts to wear out. They do not obstruct the flow so do not create a pressure drop. They offer a wide turndown or rangeability and have high accuracy, according to their specific design.

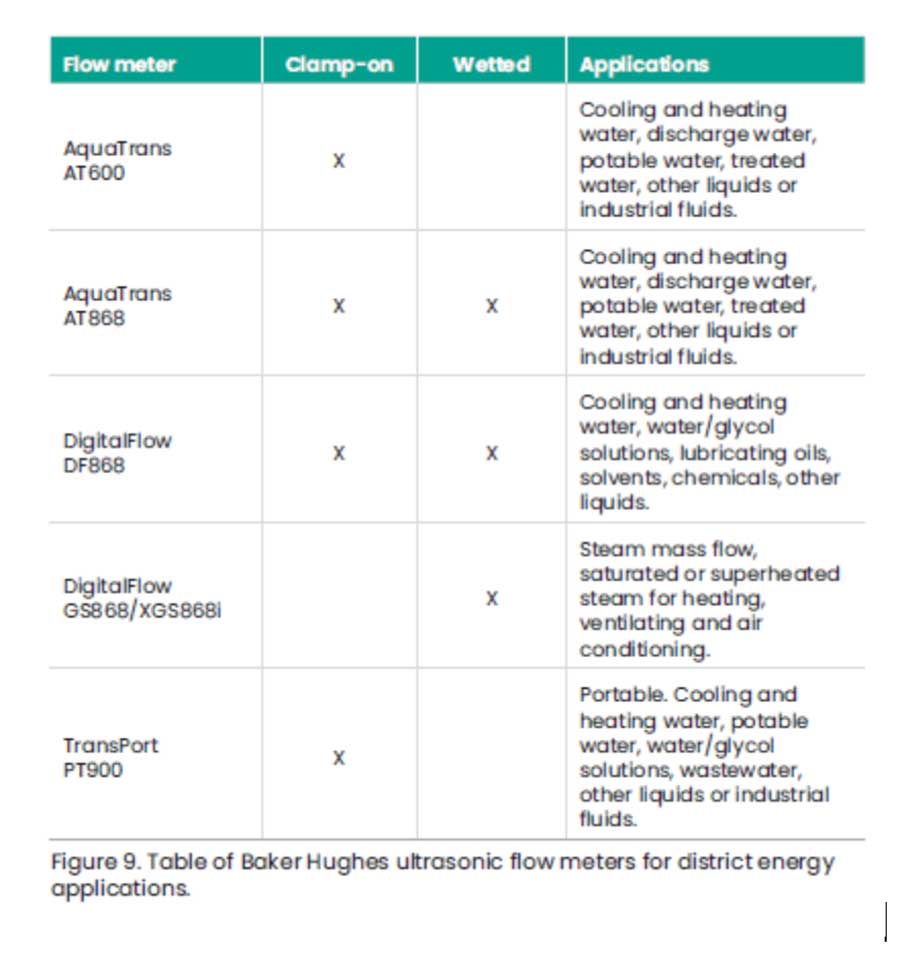

Ultrasonic flow meters for water and steam

Transit time ultrasonic flow meters can be used for both water and steam. As well as calculating actual flows, they also feature the signal processing power to provide calculation of energy delivered or removed from a particular zone or building.

Thermodynamically, this calculation relies on the equation:

ΔQ = Va?(hs-hr) where ΔQ is the rate of heat exchange, V is the fluid velocity, ? is the fluid density and hs is the enthalpy of the fluid supply and hr is the enthalpy of the fluid exit.

Enthalpy is the total heat of the fluid and is temperature and pressure dependent. It is a measurement of amount of energy, in kilojoules or BTU, contained in 1 kg or 1 lb of the fluid. For flows in pipes, the pressure is constant, so the change in enthalpy is purely dependent on the change in temperature between supply and exit.

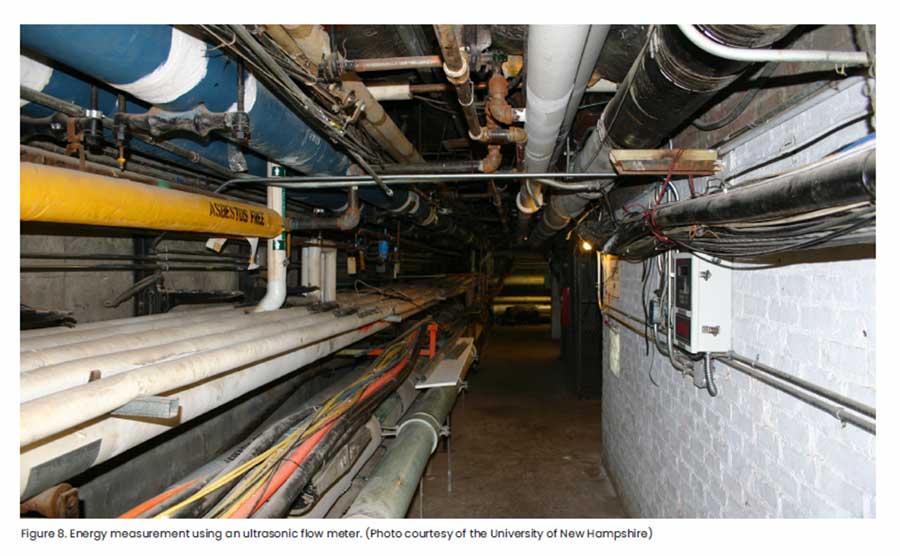

Ultrasonic flow meters, such as those from Baker Hughes, feature built-in density information and enthalpy tables for water and steam to allow exact calculation of energy usage in a range of units. They also feature RTDs to provide accurate measurement of relevant temperatures. Some flow meters offer multiple outputs to allow integration with building facilities management systems, using HART® or Modbus protocols.

Conclusions

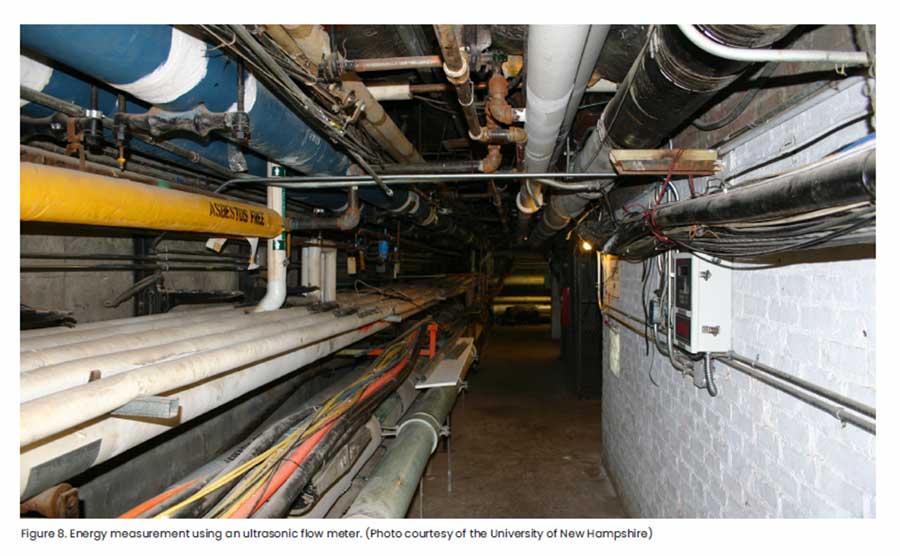

Energy efficiency is important and so monitoring it is key to any energy efficiency strategy—both to identify inefficient energy usage and to ensure that discrete zones within building complexes are accurately billed for their energy consumption. In building complexes such as university campuses and government facilities, energy monitoring relies very much on the measurement of the flow of the heating or cooling media and the conversion of this data into energy units.

There is a wide range of flow metering technologies and the selection of the correct solution to meet individual challenges requires research and comparison. The technology needs to be accurate and reliable. Preferably it should not involve a pressure drop in the flow, which is another source of energy loss. It must also be easy to use and maintain. In some applications, especially in older buildings, ease of installation can be prime concern. Turndown or rangeability of measurement is also important, especially with steam monitoring where there is a wide difference in the flow rate in summer and winter. Easy integration with modern building facilities management system can often be required.

Baker Hughes understands the need to accurately monitor, measure and analyze flow efficiency in order to combat rising energy prices and reduce waste and is continuing to invest in technology for this purpose. Our customers have been able to get critical information to improve their heating and cooling systems and to track energy usage. As a result, they continue to see improved billing accuracy, lowered maintenance costs and decreased ownership costs.

Learn More Here