SPONSORED

New Pig - Branded Feature

Getting A Grip On Slips, Trips And Falls

The deep, dark secrets your laundry service is sweeping under the rental rug

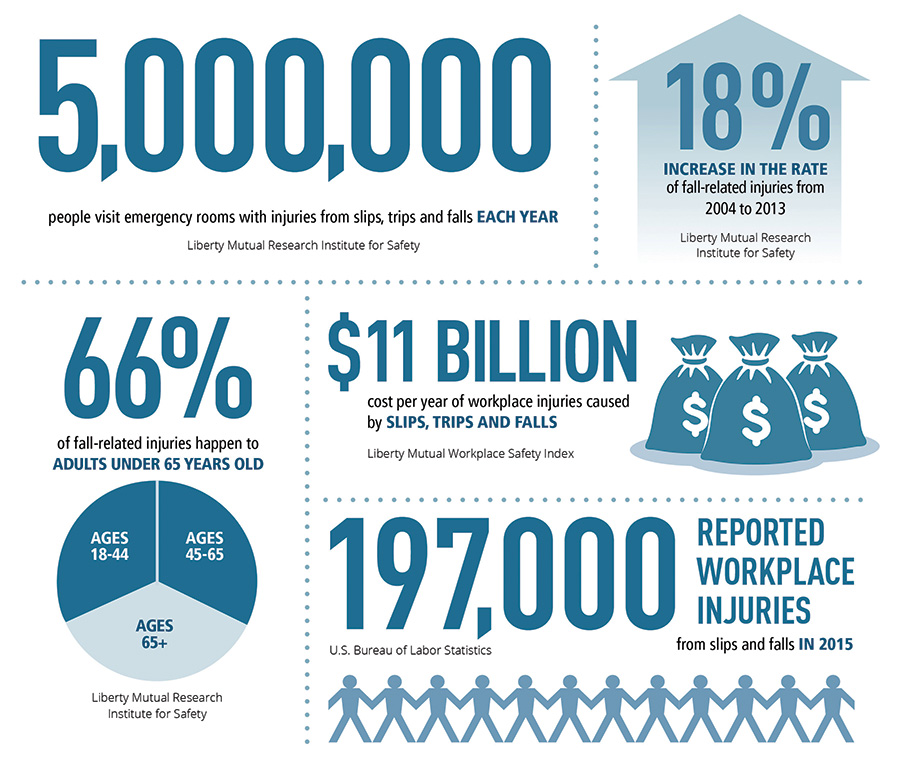

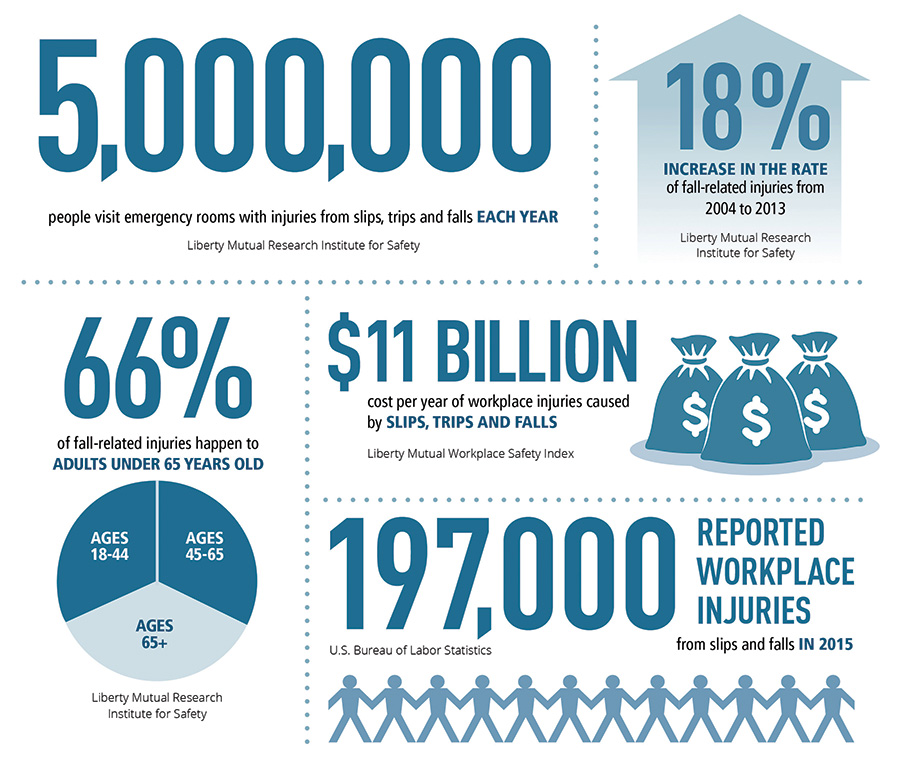

Every year, slips, trips and falls send five million people to the emergency room with sprains, strains, bruises and breaks, costing business and industry billions of dollars in workers' comp, liability claims and litigation costs. Recent numbers (see infographic) released by the Bureau of Labor Statistics and the Liberty Mutual Research Institute for Safety (LMRIS) paint a sobering picture.

Rising numbers = soaring costs.

American businesses pay $11 billion in direct costs for same-level slips, trips and falls, according to the 2017 Liberty Mutual Workplace Safety Index. And a review of the Workplace Safety Index from 1998 to 2010 showed a $2 billion increase in inflation-adjusted direct costs during that period.1

"If these numbers continue to rise in this way, falls could become the most costly injury for U.S. employers," says Wayne Maynard, CSP, CPE, Liberty Mutual Risk Control Services Product Director. "And that doesn't even include the cost of lost productivity, or the liability costs that can accrue if a customer falls at a business site."1

Risk management and commercial insurance provider Zurich North America reports that the average cost of a workers' comp claim is $18,202, and a general liability claim is $7,770. But for every $1 of direct costs, Zurich estimates that there are at least $3 of indirect — and uninsured — costs that can include overtime paid to make up for lost production, hiring and training a replacement worker, time spent investigating and reporting the accident, loss of reputation and revenue, and Occupational Safety and Health Administration (OSHA) fines. Out-of-pocket expenses can add another $54,600 to a workers' comp claim and raise general liability costs to nearly $31,000 per incident.

Prevention is a matter of priorities.

According to the National Floor Safety Institute (NFSI), slip, trip and fall prevention programs that include written plans can reduce incidents by as much as 90%. But a 2009 LMRIS survey of 231 financial decision-makers at companies with 100 or more employees reported that slips and falls ranked fifth for resource allocation — due in part to a widely held misconception that falls are a minor concern.

A 2017 floor safety survey conducted by New Pig Corporation reinforces the LMRIS findings by reporting that just 39% of their respondents considered fall prevention a top priority even though 42% confirmed at least one fall in the past year and 5% had more than five falls. Only 4% of facilities said they place their floor mats according to a strategic plan.

When asked to rank their floor safety efforts in order of importance, providing non-slippery standing and walking surfaces was ranked last, behind providing safety training, requiring proper footwear and following proper floor cleaning protocols.

"The idea that falls are simply inevitable is common but dangerous," says Wayne Maynard. "If we truly believe that falls are unavoidable, we won't try to prevent them. That is a big mistake."1

So how do you stop the slip and slide?

According to the National Safety Council, 50% of slips, trips and falls are caused by unsafe floors. Hazards range from the inherent slipperiness of the floor surface to wet weather, to contaminants like spills and overspray, to rippled floor mats. Add in variables like a person's choice of shoes, their physical condition, or their level of distraction, and accidents are bound to happen.

Along with yellow wet floor safety signs, carpeted floor mats have become a staple in facility entrances because most slips and falls occur right inside the door. There's just one problem — the mats are a known tripping hazard.

Fifty-eight percent of New Pig survey respondents confirm that they rent the carpeted mats in their entrance while 44% say they own them. And nearly 15% of these organizations report that wrinkled, bunched-up or shifting mats are the primary cause of falls in their facility.

In 2012, NFSI and the American National Standards Institute (ANSI), released the ANSI/NFSI B101.6-2012 Standard Guide For Commercial Entrance Matting In Reducing Slips, Trips And Falls, to establish best practices for selecting, installing and maintaining entrance mats and runners in commercial facilities. When the most widely used carpeted mats (including rental mats) are held up to the standard, it's clear that the bulk of the safety issues lie with the mats themselves — but the end user is ultimately responsible for their performance when they fail to work as they should.

Why don't carpeted floor mats work?

The trouble with standard-weight interior entrance runners and floor mats is the design. Most are constructed with a nylon carpet top bonded to a molded rubber back, making them durable but potentially dangerous. Here's why:

Rubber doesn't adhere to the floor.

Even with a high-traction back, carpeted floor mats don't adhere to the floor surface and depend on weight to keep them flat and in place. This makes them bulky and cumbersome, but at a little over eight ounces per square foot, they're light enough to shift under foot and cart traffic or kick out of position — creating the rippled edges and flipped-up corners that become tripping hazards.

Mike Rohrbaugh, Vice President and Division Manager of Market Basket Foods, has dealt with this problem for years, saying, "When you have shopping carts running across the mats, they will move thirty feet in the course of the day. So everybody is constantly bending over and moving them back."

Nylon carpet doesn't keep water off the floor.

Another drawback with carpeted floor mats is how quickly they become soaked in wet conditions. "The material they make those rugs out of doesn't absorb water. It just beads up on the outside. The wetter the mat gets, the worse it gets. Pretty soon, we'd see dirt tracks coming off the end of the mat. So it did nothing," says Rohrbaugh.

Why does this happen? Most floor mats are topped with nylon carpet because it's tough and abrasion-resistant. But if the carpet fibers have been treated for stain resistance, the mat is essentially water-repellent. That doesn't mean the carpet won't hold water — it will — but the fibers can't wick away the moisture and spread it out to generate an efficient drying cycle. When people walk across the mat in wet weather, water from their shoes stays where it was deposited until the carpet becomes waterlogged. Puddles form, water is tracked in, and the floor becomes slippery and dangerous.

More than half of New Pig survey respondents said their facility entrance was a primary fall location, with 37% confirming that rain and snow tracked in from outside was the main cause of falls in their building.

Replacing a saturated mat is no easy task, either. A 3' x 5' carpeted floor mat weighs about 32 pounds soaking wet, and a 3' x 10' runner twice that amount, making the job of dragging them out and hanging them to dry a back injury waiting to happen.

Welcome to the rental rut.

On the surface, renting floor mats seems like a smart alternative to the hassles of owning and maintaining them. Most commercial laundry services promote their mats as the easiest way to increase floor safety, lower maintenance costs and enhance appearance. Maybe that's why over half of the facilities using floor mats rent them. But do rental mats live up to what they promise?

Myth #1: Rental mats increase floor safety.

To be effective at removing dirt, grime and moisture, an entrance mat should fit the width of the entrance and provide about 8–10 feet of walk-off — enough for people take at least six steps. So if an entrance requires 60 square feet of coverage, the ideal is a single 6' x 10' floor mat that protects the entire area.

If a facility is renting, they may be limited to standard-weight 3' x 5', 3' x 10', 4' x 6' or 5' x 8' mats. The laundry service knows that larger, heavier mats are safer, but they actively promote the sizes and weights that are most efficient for their washers and delivery trucks. A large commercial washing machine holds 450 pounds of mats — or 27 3' x 10' runners weighing 16 pounds each, and a typical delivery truck holds 100 mats. If a facility wants larger or heavier mats they must be willing to pay a premium.

Once a facility is locked into their assortment of mat sizes, they may be forced to employ a patchwork of mats to cover large areas like the entrance. This fragmented approach virtually guarantees that the mats will move out of position and create gaps that interrupt the continuous coverage necessary to keep the floor safe.

Limited mat sizes also make it difficult to provide adequate coverage in other areas, creating slip and trip zones in transition areas, walkways and other hard-to-fit spaces. The New Pig survey reports that a primary reason why slips, trips and falls happen so frequently is that many dangerous areas are neglected. Less than 31% of respondents reported placing floor mats in customer walkways, only 41% reported placing floor mats in employee walkways and aisles, only 35% said they place them around equipment or machines, just 23% in frequent spill areas, and only 22% in the break room.

The reality: Floor mats only increase floor safety when they provide continuous, one-piece coverage that fits the space, lies flat and doesn't shift out of position. Coverage must also extend beyond the entrance to other underserved zones where slips and falls also occur.

Myth #2: Rental mats lower maintenance costs.

Depending on their schedule, a facility may have their rental mats changed weekly, every two weeks, or monthly. That means it's up to employees to keep the mats clean and in place between deliveries. Along with needing to be vacuumed and constantly straightened, dirty, bulky rental mats must also be picked up for nightly floor cleaning and replaced in the morning. Even if cleaning and straightening rental mats is considered part of an employee's daily tasks, it's still a maintenance expense for the business.

Floor mat distributors often point out that renting costs up to three times more than buying the same mat outright. And if the facility signs on with a laundry service who tacks on extra fees or other charges not included in the contract itself, or raises rates for no apparent reason, those lower maintenance costs quickly disappear.

The reality: Facilities are paying a premium for a service that still saddles them with day-to-day upkeep. If employees spend just an hour every day maintaining mats at a rate of $15 per hour, it will add more than $5,000 per year to the cost. Contract increases and extra fees also undo any potential savings.

Myth #3: Rental mats enhance appearance.

Commercial laundry services promise to maintain a facility's appearance with clean, fresh mats that complement a facility's décor. What ends up on the floor is another matter. If a facility rents six 3' x 5' gray mats per week, the laundry service will deliver six 3' x 5' gray mats. The catch is that the mats may look brand new or they may be stained, worn, and rough around the edges — the facility has to take what they get. If a mat is stained or heavily soiled while it's on the floor, the facility must clean it or put up with it until their next delivery.

The biggest problem — and the one that prompts the most customer complaints — is a direct result of the laundering process. Heat from the dryer causes the mats to ripple, producing what is commonly referred to as "bacon mat." The rippling worsens when the mats are rolled or folded, and stacked for storage and delivery. Over time, the mats buckle from being compressed by the weight of the stack. A buckled mat doesn't just look bad — if it doesn't lie flat, it will move out of position faster and create a greater tripping hazard.

The reality: Facilities have no control over the quality of the mats they receive. They may look new or they may be old and stained, and have torn edges. Either way, an enhanced appearance is no guarantee. And because the mats are rolled, they may be buckled and dangerous.

The bottom line: Laundering aggravates the structural flaws in rubber-backed, carpeted floor mats. Heat and compression buckle the rubber backing, causing permanent ripples that create even more tripping hazards. And while many facilities choose rentals because outsourcing seems to be more efficient than owning and maintaining their own mats, renting is actually an expensive, potentially dangerous option that can increase slips, trips and falls.

Introducing the next-generation floor mat.

After decades of rubber backs and carpet tops, fresh thinking about floor mat construction has emerged from New Pig, the leader in keeping workplaces clean and safe since 1985.

Using their three decades of experience with absorbents, New Pig engineers took on the problem of managing floor safety from a different perspective. Their solution is a whole new breed of floor mat: the adhesive-backed mat. This high-tech mat is constructed with both a durable, absorbent top that efficiently captures dirt, grime and moisture, and a proprietary adhesive layer that keeps it securely in place.

PIG® Grippy® Floor Mat (patent pending), the world's first adhesive-backed mat, eliminates the built-in deficiencies of rubber-backed, carpeted floor mats.

Grippy Mat stays put.

The proprietary adhesive backing on PIG Grippy Floor Mat keeps it perfectly flat and in position as long as it's in service. Because it doesn't shift, ripple or flip over, PIG Grippy Mat drastically reduces slips, trips and falls and eliminates the wasted time of adjusting mats.

Grippy Mat keeps floors cleaner.

Just like nylon carpeting, Grippy Mat effectively captures dirt and grime at the door. But unlike carpeting, Grippy Mat is also a highly efficient absorbent that pulls moisture off shoes and spreads it throughout the mat with powerful wicking action. It's this cycle of absorbing, wicking and spreading that helps Grippy Mat dry out and keep water and dirt from being tracked onto the floor.

Grippy Mat is easy to maintain.

PIG Grippy Floor Mat stays in place to work seamlessly with standard floor cleaning methods. Grippy Mat can be swept, mopped, vacuumed or cleaned with a floor scrubber. This allows cleaning crews to treat Grippy Mat as a part of the floor and keep it clean and fresh without extra work or inconvenience.

Grippy Mat enhances appearance.

The top layer material on Grippy Mat is virtually indestructible and because it won't fray or crush in extreme foot, cart and wheeled traffic, it looks good longer. It stays put, doesn't bunch up and looks neat and appealing as long as it's on the floor.

Grippy Mat keeps floors safer.

PIG Grippy Mat's high-traction surface is certified by the National Floor Safety Institute (NFSI) and can help reduce slip-and-fall claims by up to 90%. Grippy Mat is the only floor mat that can be rolled out and cut to size to provide the necessary walk-off coverage in entrances.

Unlike standard-sized rubber mats, Grippy Mat can be configured to any size or shape to cover neglected walk zones and hard-to-fit areas around displays, floor drains or pillars.

Grippy Mat will never create a tripping hazard. The adhesive back keeps it securely in place to eliminate the rippling, shifting and flipping over that make rubber mats a danger. Because it's super thin, Grippy Mat is ADA compliant and nearly indistinguishable in height profile from the rest of the floor surface — eliminating the edges that curl and catch on shoes and cart wheels.

Grippy Mat sets a new standard.

Adhesive-backed mats don't just improve on the old standard of carpet on rubber, they're a completely different category of floor mats. With PIG Grippy Floor Mat, every facility can take charge of their floors and elevate safety to a whole new level.

1. From Research to Reality Scientific Update, Volume 18, Number 2, Fall Injuries: Inevitable or Preventable? 2016, Liberty Mutual Research Institute for Safety