« Back to Facilities Management Roofing Category Home

Preventive Maintenance Considerations for Commercial Roofing Systems

November 9, 2016

- Roofing

Out of sight should not mean out of mind when it comes to maintenance and engineering managers and their roofs.

While the roof system may sometimes be an unnoticed component of institutional and commercial facilities, it is often one of the most important. After all, the roof is a building's first line of defense against hazards such as wind, rain, ice, snow, extreme heat and other inclement weather conditions.

However, commercial roofing systems often go overlooked until they leak or show other signs of failure. The reality is that commercial buildings are not designed to be indestructible — and neither are the roofs that top them. As with our bodies or the cars we drive, a good preventive maintenance program can help sustain your roof’s functionality.

Maintenance considerations

There are two basic approaches to commercial roofing maintenance: reactive and proactive.

Reactive maintenance involves remedying problems as they appear. Similar to seeing the dentist only when there is a major issue, this approach can upset owners due to costly, time-sensitive repairs, which may have been avoided with proper inspection and maintenance.

Proactive maintenance looks to prevent or delay repairs by means of regular and continuous inspections, care and attention. This approach is similar to brushing twice daily and visiting your dentist for a routine checkup every six months.

Effective preventive maintenance programs — regardless of the roofing materials used — involve the following key phases:

- An assessment of the commercial roof system’s existing conditions and performance at least two times per year — once in the fall prior to the winter season and once in the spring after the winter season.

- The creation of a data file on the building and its commercial roofing assembly.

- A discussion and implementation of a maintenance program that includes any repairs required to prevent potential problem areas and to return the commercial roofing assembly to the expected level of performance.

- Continuous documentation and retention of files generated as a result of the maintenance program

Commercial roof assessment

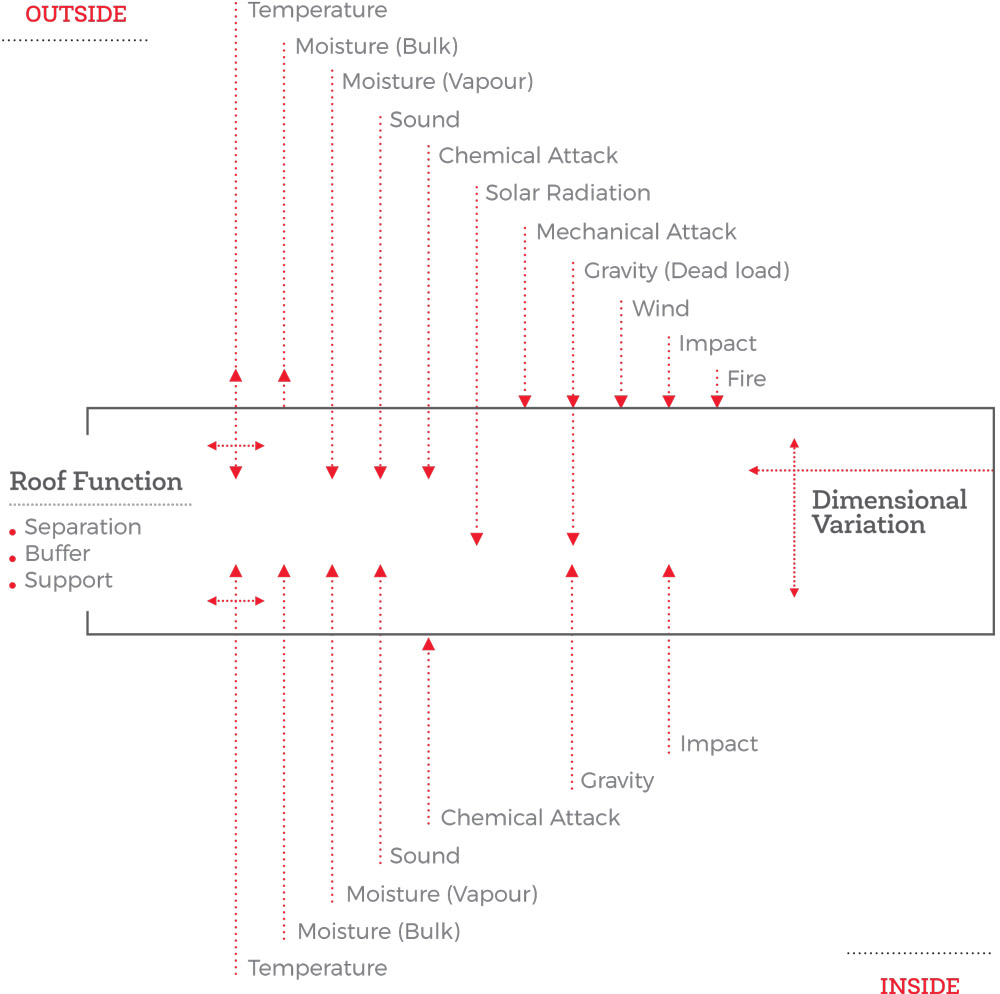

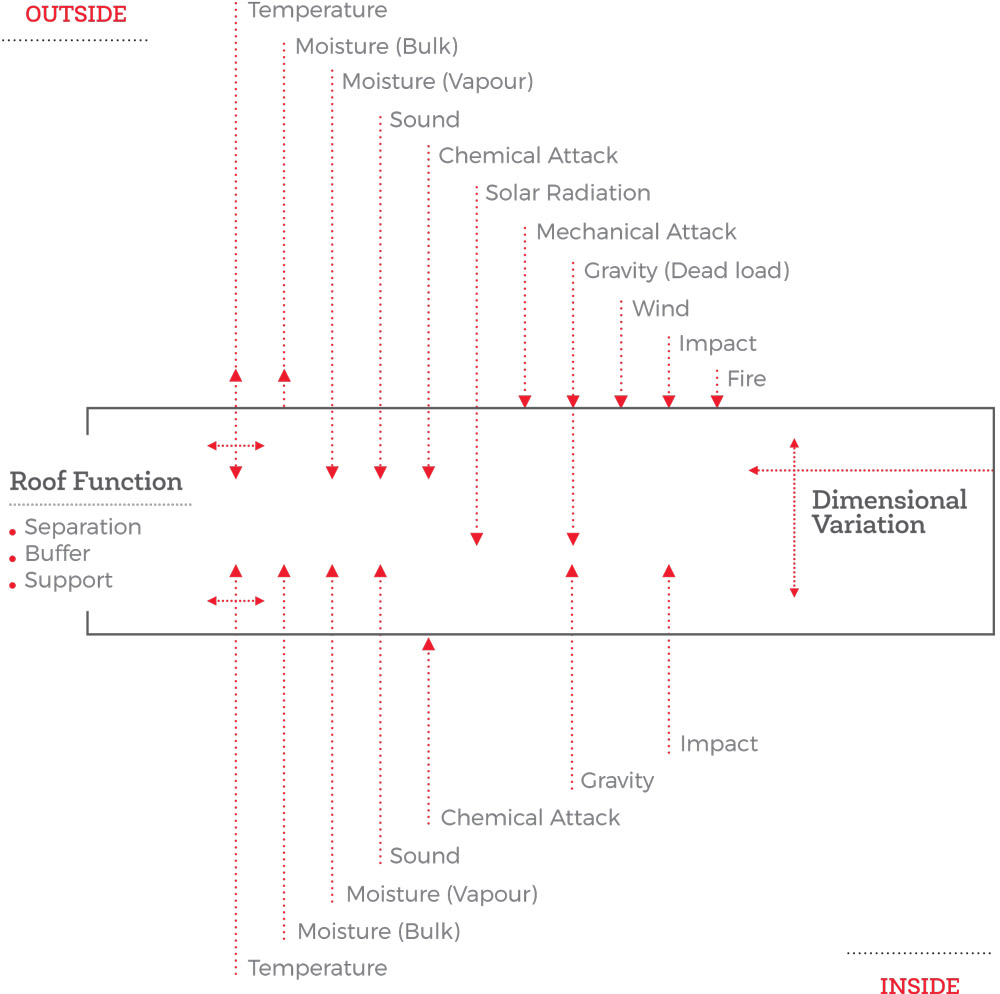

Given the various loads imposed on commercial roof assemblies — both structurally and environmentally on both sides of the partition as shown by the graphic accompanying this article — a comprehensive assessment of the commercial roof condition at regular intervals (at minimum, two times per year) is essential to good preventive maintenance practices.

This commercial roof assessment can be broken down into three basic steps:

- Step 1: Physical Inspection of the Exterior of the Building

The first step focuses on the portions of the wall that meet the roof line, or the parapet. It is important to visually inspect the roof parapet for areas that might be deteriorating or leaking, where rain may be penetrating the roof assembly or condensation may be occurring. Also check for possible signs of movement in the roof assembly, such as blistering, ridging, lifting of insulation or displaced metal flashings.

Common warning signs of a problem in the roof’s exterior assembly include the presence of efflorescence, or salt deposits, and/or cracking of masonry.

- Step 2: Interior Inspection of Roof

An evaluation of the interior side of the commercial roofing assembly is also important to assess possible problem areas. Staining on ceiling tiles or evidence of leakage on the interior floor are easy identification signs for a roof in need of repair. Other problem areas include any deformations in the decking or faulty installation techniques used for mechanical equipment in the roof assembly.

The interior of the building also provides insight into the operating conditions of the facility (such as high relative humidity levels), which may also lead to or be causing problems for the roof above.

- Step 3: Rooftop Inspection

The final step is to observe the condition of the actual commercial roof assembly.

The appearance of a well-maintained roof will have mechanical equipment featuring fully bonded caulking or seals and the presence of designated and properly prepared traffic paths for workers. Also, there should not be any evidence of debris or ponding water. If there are blocked drains, algae, heavily trafficked or bare spots, or a buildup of debris on the roof, it is usually a good sign that the roof assembly has been neglected.

Other critical components of the commercial roofing assembly that should be evaluated in the rooftop inspection include the integrity of the seams of the membrane and flashings, the condition of any penetrations and the seals used around them, as well as any evidence of movement in the assembly.

If a data file is not readily available on the type of roofing membrane and assembly components, be sure to document these for future inspections. A sketch of the rooftop and various equipment locations are also useful.

The most successful preventive maintenance programs include regular, complete and consistent examination, as well as follow-up on the findings of the assessment. Several roofing manufacturers, including IKO, advocate a minimum of two maintenance inspections per year — but the more frequent, the better. If the commercial roofing assembly is exposed to severe, inclement weather or heavy or frequent rains, additional inspections should be scheduled.

With routine, quality maintenance, and preventive repairs as needed, building owners can help to ensure that the performance of their commercial roofing assembly is sustained. Inspections and repairs should always be performed by trained professionals.

For more information and a list of IKO professional contractors in your area, visit www.iko.com/commercial.

Thomas Garvey is a product specialist for IKO North America.