« Back to Facilities Management Maintenance & Operations Category Home

Infrared Thermal Imaging Helps Pinpoint Problems with Electrical Systems

May 9, 2018

- Maintenance & Operations

By John H. Waggoner

Heat is a byproduct of operating any sized electrical circuit. Most problems in electrical systems display themselves in terms of heat. Facility staff must be able to classify a circuit as normal when the load is on or identify when it is abnormal and identify the issues that present — finding hot spots that need attention. Infrared thermography — also called thermal imaging — is a non-contact method that includes cameras that help facility staff find and solve problems with electrical equipment quicker and more safely. The newest cameras combine both thermal imaging and electrical measurement features in one inspection, troubleshooting, and diagnostic tool.

Methods for Inspecting and Analyzing Electrical Systems

In the past, the only way to inspect and analyze electrical systems was with hands-on testing — usually done after turning off the power to make sure it was electrically safe. Facility staff members typically have gone in with testing equipment and tools to connect test leads to determine if there are any issues. Many have used contact measurement techniques featuring thermocouples, which produce a temperature-dependent voltage that can be interpreted to measure heat.

With these traditional inspection and maintenance methods, the user cannot see all the possible issues, but instead must rely on guesswork, checking out connections one by one. This method does not guarantee that heat-related conditions will be solved, because turning off the power removes the load. One can measure if a circuit is overloaded, but when the power is off it is not always possible to know for sure if the problem in the circuit was fixed.

In recent years, facility staff also began using spot radiometers: small hand-held non-contact devices that can be pointed at a target to obtain a temperature measurement. Radiometers provide acceptable measurements within certain limits, but no visual imagery is available.

A step up from direct measurement and spot radiometry is thermal imaging, which detects infrared energy emitted from an object, converts it to temperature, and displays an image of temperature distribution, called a thermogram. Since infrared radiation is emitted by all objects with a temperature above absolute zero, thermography makes it possible to see the environment with or without visible illumination.

Thermal imaging provides a far higher ability to analyze, recommend, and diagnose. With thermal imaging, one can use a camera on a circuit breaker to determine if connections are loose, if there is too great a load on the breaker, and if there are any issues with the breaker contacts. Facility staff can find the problem, fix it, then go back with the thermal camera and take an image to verify that the work done has actually solved the problem.

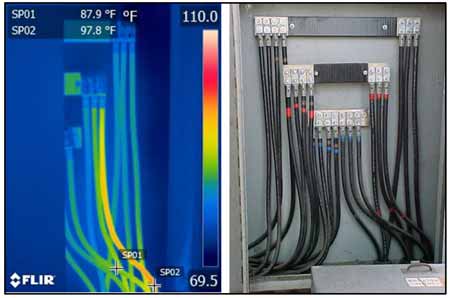

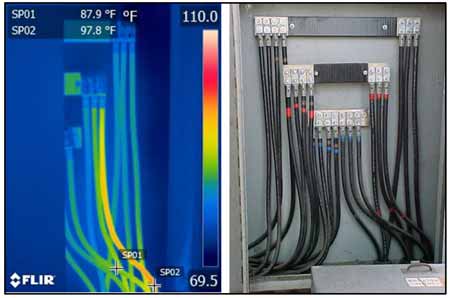

Caption: In this large junction box, one conductor was hotter than the eight others. Using the thermal imaging camera, technicians located the problem from 150 feet back.

A wide range of electrical equipment can be inspected with thermal imagers, including transformers, switchgear components, breakers, fused disconnects, non-fused disconnects, conductors, terminations, contactors, control wiring terminations, buss duct (open and enclosed), distribution and branch circuit breaker panels, and motors.

Thermal imaging is used for voltages below 1000 volts, largely for enclosed equipment that supports industrial and commercial operations. Utilities also rely on it extensively for medium and high voltage equipment (overhead lines and connections), and for substation equipment (breakers, switches, transformers, capacitors, and voltage regulators), to name a few.

Benefits of Thermal Imaging

Thermal imaging has three main benefits. First, it is a non-contact approach, so facility staff members do not have to actually touch electrical equipment to determine if the heat is within normal operating temperatures or has moved into abnormal temperatures.

Second, facility staff can use thermal cameras as a visual tool to demonstrate to others the severity of electrical problems. Infrared cameras produce an image of a target that is similar to visual photographs. Many also produce a visual image that can be placed next to the thermal image for a side-by-side comparison.

The third benefit is that thermal imaging can be performed in real time. Over the past decade, video-capture technology for infrared cameras has greatly improved. This allows users to observe and analyze electrical equipment as it heats up and begins to operate, as it operates under normal conditions over time, and as the target cools down. There is also the ability to watch fast-moving targets, as the recording speed, or frames-per-second, has improved. Cameras that record at higher frame rates allow the user to observe targets that are changing temperature rapidly, or those that are moving very fast.

Thermal Imaging Equipment Options

There is a wide range of thermography equipment, varying from low resolution cameras costing $400 to high resolution cameras costing more than $40,000. The difference among thermal imaging resolutions affects how close one needs to stand to image a target, and the different accessories available for viewing and adjusting the camera and measuring temperature.

Higher-end thermal imaging technology can produce up to 1024 x 768 pixel images. Dynamic focus control, continuous autofocus, and a user-friendly interface with an ergonomic design and rotating optical block make it easier to do numerous inspections in one day and to scan at difficult angles.

Another option that has recently come on the market are meters that combine thermal imaging with electrical measurement features in one inspection, troubleshooting, and diagnostic tool. These new meters can take voltage, current, and millivolt drop measurements while also taking an infrared image with the same device. This offers more information to make a determination, provides images to confirm the diagnosis, and offers proof showing where the problems are. Combining several tools into one reduces the total amount of time it takes to diagnose issues and increases a user’s speed. It also makes the user more skillful at troubleshooting, repair, and maintenance work.

Thermal imaging has been used all over the world to diagnose and solve electrical system problems. Users benefit by being able to “see heat” with new thermal imaging equipment, which helps pinpoint what the problem is, where it is, and how best to repair the problem.

John H. Waggoner is a senior instructor, Infrared Training Center, FLIR Systems Inc.