Dry-erase Coatings and Chalkboard Coatings: Lessons for FMs

These two types of coatings take different routes to a similar end.

Dry-erase coatings and chalkboard coatings are both designed to the written on, but they have very different characteristics. Dry-erase coatings are marked on with special dry-erase pens, while chalkboard coatings are marked on with ordinary chalk.

Dry-erase coatings are sometimes called marker-board coatings or white-board coatings, and they are usually produced by specialty coating manufacturers.

Dry-erase coatings are often used in conference rooms, lecture halls, classrooms, day care facilities, or wherever a simple and economical erasable writing surface is needed. As noted, special dry-erase pens leave an erasable mark on dry-erase coatings, and these markers are available in many colors. They produce very little or no dust or residue when writing or erasing because the eraser picks up the residue with little to none of it being deposited on the floor. As a bonus, surfaces coated with white dry-erase coatings can also be used as projection screens.

Dry-erase coatings are often applied over steel or aluminum sheet metal. However, they can also be applied over smooth continuous surfaces such as drywall. When applied over drywall, the drywall should be finished to a level 5 finish. If applied over masonry or concrete, use an alkali-resistant filler to fill pores and smooth the surface. However, masonry and concrete surfaces will not be as smooth as metal or drywall.

Dry-erase coatings are normally applied as a colored base coat and covered with a clear, hard, smooth, erasable finish coat. Since this is a smooth writing or projection surface, surface imperfections, such as runs, drips, sags, bumps, and depressions can make a significant appearance during use. Some manufacturers claim that dry-erase coatings can be applied over existing paint. If application over an existing surface is a requirement, that claim should be verified. Also, when preparing a dry-erase board, consider trays to hold the dry-erase pens. Trays are usually made of aluminum, wood, or plastic and can be purchased from school or office supply firms. Consider tray location, size, and attachment when purchasing.

Chalkboard coatings

Chalkboard coatings are usually produced by specialty-coating manufacturers and typically have a low sheen that reduces glare and reflection. Black is the usual color. Unlike dry-erase coatings, chalkboard coatings are marked on with ordinary chalk, which can be messy, especially during erasing. Also, chalk is limited in colors.

Chalkboard coatings can be applied over drywall board, wood, metal, concrete, and masonry surfaces. Chalkboard coatings work best over smooth non-porous surfaces, and they usually can be reapplied over worn chalkboard coatings. Like dry-erase coatings, drywall substrates require a level 5 finish. Chalkboard coatings are usually used in the same locations as dry-erase coatings. However, chalkboard coatings are not as durable as actual chalkboard. Chalkboard coatings are softer than slate chalkboards. Repetitive writing, erasing, and cleaning tend to wear down the surface. The same considerations for chalk rail should be considered when chalkboard coatings are used.

Proper primers, as recommended by the manufacturer, are required, and the primer should be alkali-resistant if the substrate is concrete or masonry. When properly prepared and thinned, chalkboard coatings can be applied by brush, roller, or spray.

Paints and Coatings 101: What’s in a Name?

Paints can be divided into two primary categories - paints and protective coatings or just coatings; however, the terms are often used interchangeably. For this article, the term coatings will be used.

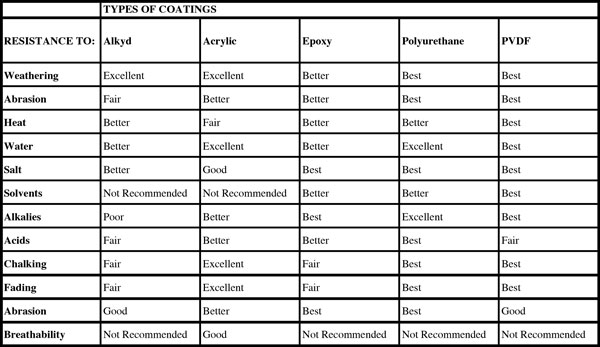

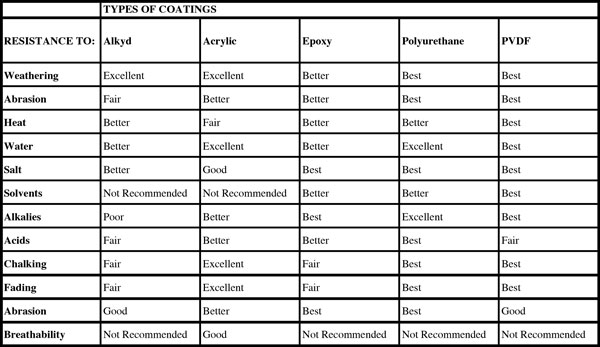

A paint's primary purpose is aesthetic — to change the appearance of the substrates, such as wood, drywall, metal, masonry, concrete, etc. — and can provide protection as a secondary purpose. A coating's primary purpose is to protect a substrate from abrasion, moisture, UV, fading, corrosion, etc., and as a secondary purpose to provide aesthetics. Paint and coatings can also be water-based or solvent-based high-performance generics such as alkyd, epoxy, polyurethane, and acrylic.

Table 1 compares the performance properties of the most common paint and coating generics. (The scale used is Not Recommended, Poor, Fair, Good, Better, Best, Excellent.)

For more information

For more detailed information on paints and coatings, consult the following published articles by this author:

1. Crissinger, Joseph L. ("Cris"), “A Drop in the Bucket.” American Schools and Universities, November 20 04, pp.348-350. http://www.asumag.com/mag/drop-bucket

2. Crissinger, Joseph L. ("Cris"), “Fundamentals of Paint Failures.” Interface, Technical Journal of RCI, September 2005, pp.32-44.

3. Crissinger, Joseph L. ("Cris"), “Considerations for Coastal Coatings, Part 1.” Interface, Technical Journal of RCI, March 2007, pp. 24-40. http://rci-online.org/wp-content/uploads/2007-03-crissinger.pdf

4. Crissinger, Joseph L. ("Cris"), “Considerations for Coastal Coatings, Part 2.” Interface, Technical Journal of RCI, June 2007, pp.32-36. http://rci-online.org/wp-content/uploads/2007-06-crissinger.pdf

5. Crissinger, Joseph L. ("Cris"), “Considerations for Coastal Coatings, Part 3.” Interface, Technical Journal of RCI, July 2007, pp.33-39. http://rci-online.org/wp-content/uploads/2007-07-crissinger.pdf

6. Crissinger, Joseph L. ("Cris"), “The Perils of Glossing Over Paint Sheen.” Construction Specifier, July 2009, pp. 40-46.

7. Crissinger, Joseph L. ("Cris"), “Corrosion: What’s Eating Your Metal, Part 1.” Interface, Technical Journal of RCI, July 2013, pp. 4-19.

8. Crissinger, Joseph L. ("Cris"), “Corrosion: What’s Eating Your Metal, Part 2.” Interface, Technical Journal of RCI, September 2013, pp. 29-36.

9. https://www.theexpertinstitute.com/floor-safety-expert-outlines-testing-standards-for-slip-resistance-of-interior-tile/

10. https://safetydirectamerica.com/ansi-standards-floor-slip-resistance

Joseph (Cris) Crissinger, CSI, CCS, CCCA, ASQ, is a construction specifications, materials, and building systems consultant in Spartanburg, S.C. He has authored numerous technical articles on construction materials and testing; and has twice received the Richard M. Horowitz Award from the Roof Consultants’ Institute (RCI) for best technical articles. Crissinger can be reached at specalyze@reagan.com.

Related Topics: