Integrating CMMS with Other Building Systems

CMMS capabilities hold the potential to open doors to coordinating and blending other facility-related programs for controlling costs, such as energy efficiency programs, pursuit of LEED certification, and retrocommissioning. Because such efforts may also be computer-based, parallels and shortcuts may exist wherein CMMS programs import and export information from and to other programs, saving time and work hours in the process. The end result may be a reduction in necessary maintenance, fewer (or less frequent) service calls, and lower energy bills.

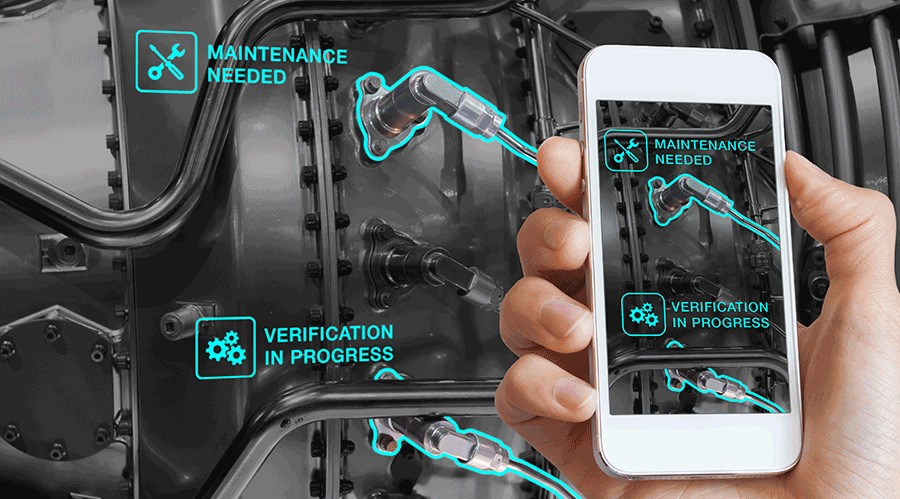

Some CMMS programs, for example, push the envelope by adding "predictive" or "condition-based" capabilities that involve automated data collection on such variables as run time, power consumption, operating temperature/pressure, and other characteristics of mechanical equipment. Such data may also be collected by energy management systems (EMS), customer-owned submeters, and data loggers installed for measurement and verification programs as part of energy-related efforts.

Some CMMS programs use such data to predict when maintenance might be needed, rather than blindly scheduling it based on rules of thumb or past experience with failures.

For example, with the ever-increasing use of variable speed drives for air and water systems, scheduling maintenance the same as for constant volume systems may result in wasted personnel time and excessive lubrication. Through a combination of learning algorithms, benchmarking, and user-controllable settings, the CMMS programs seek to predict when maintenance is required, rather than merely scheduling it based on a routine.

Where energy consumption or demand may be an indicator of a need for maintenance, such programs may require submeters. The same types of meters may be usable by demand-response programs now supported in more than half the states and some Canadian provinces. Many energy performance contracts also require measurement and verification procedures that involve long-term metering of energy use. Some states offer funding for such meters and the data acquisition systems needed to gather and catalog their data. Smart facility managers keep a lookout for ways to secure double duty out of such opportunities by using the same data gathered for one process to help cut costs of others. Having a system that can seamlessly perform such data interactions may go a long way to securing the most value with the least work.

In one case, a facility used flow and temperature data from a condensate meter to do two things: calculate the thermal energy purchased from a district steam supplier while also monitoring the condition of some of its major steam traps. A much higher condensate temperature may be a sign of traps blowing steam instead of limiting its flow, potentially wasting fuel dollars and creating room temperature problems. Such data may then automatically cue a work order to correct the situation.

When pursuing LEED certification for existing or new buildings, points are given for installation of metering that tracks energy and water-related consumption. Some of the same meters that may yield such credits may also expand CMMS capabilities to minimize energy and environmental impacts. Any effort to expand metering for LEED points should therefore be coordinated with ways to expand one's CMMS monitoring capabilities to double the bang for the buck.

Retrocommissioning is often the first recommendation of an energy audit because of its short payback. It typically involves only minimal mechanical repairs because it is simply restoring a facility's existing control systems to proper order. But some have been daunted by its occasionally high cost — one study found an average cost of $.25 a square foot — and its often lengthy and invasive procedures. Every control point must be identified, catalogued, tested, and — if needed — recalibrated or repaired.

Retrocommissioning And Beyond

One savvy facility manager found ways to link up previously unused capabilities of his CMMS to provide information that truncated the retrocommissioning process and cost. Like some aspects of energy management and building automation systems, potentially powerful capabilities of CMMS software often remain unused due to a lack of training, poor setup, or loss of software documentation.

A more advanced version of retrocommissioning, called "monitoring-based commissioning" (MBCx), also runs parallel to advanced CMMS activities. Many of the characteristics of the MBCx process are available in or expandable for existing CMMS programs, but often remain unused. As pursued by a project supported by the California Energy Commission, the MBCx approach is designed to avoid the usual degradation of systems over time that often follows standard commissioning. Like some sophisticated CMMS programs, MBCx involves ongoing collection of operating data linked to the performance of building equipment, with a focus on those that consume energy.

According to a September 2008 summary of this effort, "MBCx provides the ability to trend and benchmark building-performance data continuously. By serving as a baseline for comparison with subsequent data sets, this information can be used to alert operators when performance starts to degrade and help them determine what actions to take."

When implemented across a portfolio of 40 university campus buildings, this process produced a median reduction of 10 percent of total annual energy use and a median reduction in peak electric demand of 5 percent. The median payback period was 2.4 years. In one building, the process found that "discomfort calls and extreme temperature differencesÉwere caused by faulty thermostat calibration and inoperative damper actuator or reheat valves, and not by an undersized chiller," which was previously considered the culprit. "This led to a shift in retrofit priorities away from a new chiller and to new digital controls."

Where a CMMS already exists, pursuing such success may involve little more than a review of its capabilities, the addition of a few measurement points, and leveraging those strengths to new ends.

Lindsay Audin is president of EnergyWiz, an energy consulting firm based in Croton, N.Y. He is a contributing editor for Building Operating Management.

Related Topics: