The primary drawback of UV-C technology is the need to implement safety protocols to protect workers and building occupants from exposure.

The primary drawback of UV-C technology is the need to implement safety protocols to protect workers and building occupants from exposure.Understanding How UV-C Light Can Effectively Combat COVID-19

To maximize the impact of UV-C technology, managers need to ensure specification and installation address key issues.

OTHER PARTS OF THIS ARTICLEPt. 1: This Page

Nearly 150 years ago, scientists discovered that ultraviolet (UV) light was effective in disinfecting surfaces. Since then, it has been widely used, primarily in water purification systems and healthcare facilities. Now, it also has become an effective weapon in the fight against COVID-19.

What makes UV light effective against COVID-19 is its ability to interact with the DNA and RNA molecules in the coronavirus, making them inactive and, therefore, non-infectious. To bring the benefits of UV-C technology to institutional and commercial facilities, maintenance and engineering managers specifying UV light technology must ensure the installation meets three conditions. The UV light must be of the proper wavelength, the exposure must be intense enough, and the time of exposure must be long enough.

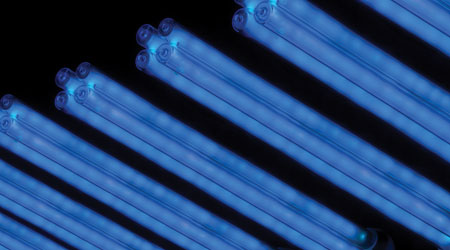

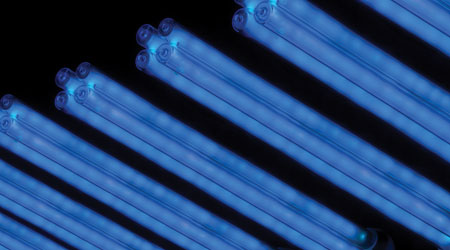

UV-C: A closer look

UV light comes in wavelengths of 10-400 nanometers (nm). Not all wavelengths work equally well at destroying viruses. Researchers found that those in the range of 200-280 nm — known as UV-C light — are the most effective, destroying up to 99 percent of the virus in exposure tests. Actual destruction rates depend on the intensity of the light and the length of time of exposure.

Unfortunately, UV-C light is not safe for human exposure because it can damage skin and eyes. It also can damage building materials, causing them to become brittle, and it can change their color. But with proper placement, shielding and safety precautions, the application of UV-C light can be an effective tool against COVID-19.

Three primary types of UV-C lamps are in use today: low- and medium-pressure mercury lamps; pulsed xenon arc lamps; and lamps that use LED technology. All three offer the advantages of low energy use, the reduced need for HVAC coil cleaning, improved coil efficiency due to reduced biological growth on its surfaces, and the elimination of the need for using harsh chemicals within the system. The primary drawback of UV-C technology is the need to implement safety protocols to protect workers and building occupants from exposure.

Facilities are installing UV-C technology in HVAC systems in two primary ways: in-duct systems and upper-room installations.

In-duct systems

In-duct systems use UV-C emitting lamps installed in HVAC ductwork — typically, close to the coil. Since the time of exposure and the intensity of the light determine lamp effectiveness, installers can coat the interior of the duct in the lamp location with a reflective material to improve exposure.

Installation is straightforward, but for the lamps to be effective, designers must take into consideration the volume and velocity of the airflow in the duct. Too little exposure, and the percentage of airborne RNA molecules deactivated will fall. Even at a high exposure rate and a low flow rate, the systems will not achieve 100 percent virus deactivation.

Since UV-C light is harmful to skin and eyes and can cause permanent damage, it is essential that several precautionary steps be taken. Access panels near the UV lamp must include auto-shutoff switches to prevent accidental exposure of maintenance technicians to the UV light. Similarly, inspection windows that technicians use to confirm the lamps are operational must be constructed from materials that block UV-C wavelengths.

In-duct UV-C systems offer the advantages of being low energy use and low installation and operation costs. Since they operate in an enclosed system, they also offer low risk of exposure to building occupants.

While the systems can be effective in deactivating viruses, they are not 100 percent effective. To deactivate the virus, it must be exposed for a certain period of time and under the right conditions. If the air velocity is too high, exposure will be limited and might not be sufficient to deactivate all of the virus present in the airflow. Dust and moisture entrained in the airflow can shield the virus from the UV-C light, and any buildup of dust or dirt on the lamps will reduce light output, so it is essential that systems be carefully designed to provide the maximum exposure.

Equally important, technicians must regularly inspect and maintain systems. One side benefit of the in-duct systems is their ability to prevent the buildup of biological material on evaporator coils. Constant exposure of the coils to UV-C light has an efficacy rate of 90 percent or greater for coil surfaces, reducing the frequency with which technicians must clean coils. Again, the actual efficacy rate depends on the intensity of the light and how fully the coil is illuminated.

Upper-room systems

Upper-room UV-C installations take a different approach from in-duct systems. Instead of installing lamps in the HVAC ductwork, installers place the lamps in the upper levels of rooms with high ceilings. Specially designed fixtures placed on walls direct the UV-C light upward away from the occupants, disinfecting the room's upper air volume. With proper air movement in the room, the system can disinfect a high volume of air constantly.

Installers can enhance the performance if air movement is increased with the installation of ceiling fans. With many HVAC systems introducing air into the conditioned space through ceiling diffusers, the systems disinfect ventilation air as it is being introduced into the space.

What makes the upper-room design effective is that it attacks the virus at its point of introduction into the occupied space. One of the most common ways COVID-19 is transmitted is from person to person. By speaking, coughing and sneezing, people expel water droplets containing the virus into the air. Larger droplets might fall to surfaces quickly, but smaller ones can remain airborne for several minutes and move via the airflow. By disinfecting the air where this transmission potentially takes place, upper-room systems can reduce transmission rates significantly.

Since UV-C light is not safe for human exposure, these systems must be designed and operated carefully. No lamps can be installed in such a manner that they are visible to occupants anywhere in the room. The ceiling and wall finish and materials also must be evaluated to ensure that they absorb and not reflect UV light. Any finishes and components in the room exposed to the light must be evaluated for possible deterioration as the result of exposure.

As with in-duct systems, upper-room systems offer the advantages of disinfecting large volumes of air while using minimal amounts of energy. They also have relatively low maintenance requirements, and they do not use harsh chemicals. As with in-duct systems, they must be carefully designed in order to be effective while posing no risk to building occupants. Their major drawbacks include higher installation cost and that use is limited to high-ceiling areas.

System selection

One size of UV-C lighting system does not fit all applications. As a result, managers must ensure each system is carefully designed and installed in order to gain the maximum benefit.

The key to success is uniform distribution of UV light across the entire duct or upper-room area. Designers must select and properly place the lamps to achieve this coverage.

Lamps and their fixtures also must be suitable for operation throughout the temperature and humidity range typically found in the duct system, and lamps must be installed so they are readily accessible for cleaning, inspection and replacement.

James Piper, P.E. is a national consultant based in Bowie, Md. He has more than 35 years of experience with facilities maintenance, engineering and management issues.

Related Topics: