Managers Turn to UV Lighting to Combat COVID-19

Ultraviolet light gets backing from CDC, ASHRAE as effective for reducing infections.

Interest has peaked during the past year among maintenance and engineering managers about how ultraviolet light (UV) technology can be used more readily as part of an overall, more robust disinfection program in institutional and commercial facilities.

As the COVID-19 pandemic continues, managers continue searching for more methods to keep common areas such as lobbies and waiting areas, offices, cafeterias, hallways, restrooms, and other high-traffic sections, safer for workers, patients, and visitors, says Jeannine Wang of Acuity Brands Lighting.

“Because lighting is necessary for occupied spaces, integrating specifically UV-C technology into lighting systems where reduction of pathogens, such as bacteria and viruses, is desired makes practical sense,” Wang says. “Using luminaires as a delivery system allows facilities to take advantage of locations where power is already distributed. This enables the disinfection technology to be added as a layer of functionality to necessary illumination using the luminaire’s intelligent control capabilities.”

Integrating UV with luminaires also creates the opportunity to provide local treatment within the space where the pathogens are being introduced into the environment.

CDC, ASHRAE approved

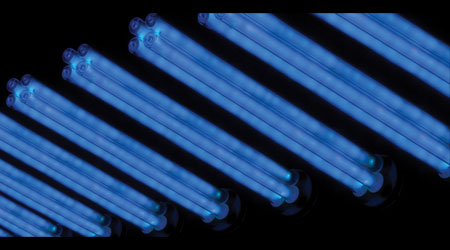

UV germicidal irradiation, including UVGI or UV-C energy, is an ideal microbial disinfectant and HVAC energy-saver up to 20 percent, and it extends air handling unit (AHU) life expectancy, says Daniel Jones of UV Resources.

“UV-C is an ideal disinfectant that inactivates infectious pathogens, reducing concentrations of infectious agents, even drug-resistant viruses and germs,” says Jones, who adds that the Centers for Disease Control & Prevention (CDC) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) have recommended germicidal UV-C as one technology that can “reduce the risk of dissemination of infectious aerosols in buildings and transportation environments.”

Through a process known as photodimerization, UV-C energy destroys a germ’s nucleic acids and protein structure by creating dimer lesions, which prevent microorganisms from infecting and reproducing, Jones says. This pathogen deactivation process also occurs without creating chemicals, VOCs, or dangerous byproducts.

In addition to reducing HVAC surface and airborne bacteria, germicidal UV is used to supplement and improve other infection-control strategies, such as room air exchange rates.

The energy-saving aspect of UV-C means that its wavelength can reduce HVAC coil pressure drop caused by a build-up of biofilm, which also improves heat transfer efficiency by up to 14.5 percent, Jones says.[Text Wrapping Break]

“As air-conditioning equipment ages, its ability to maintain adequate space temperatures and humidity levels declines,” he says. “Most often, that’s due to the AHU cooling coils’ decreased ability to remove both heat and water from the air. Evidence shows this drop in performance can occur within five years of startup and less due to the gradual build-up of contaminants on coil surfaces.

“This accumulation of material means the AHU’s coil is removing less heat, and the fan is working harder to move less air. As a result, the space temperature and humidity levels are elevated.”

UV-C also consistently improves HVAC performance. For new installations, the UV-C wavelength maintains a clean coil’s condition, Jones says. For existing applications, UV-C energy degrades organic materials deposited on coil fin and tube surfaces.

“As a result of this cleaning action, a coil’s open area remains at as-built parameters or returns HVAC system fouled coils to the original, designed performance standards,” Jones says. “In addition, the pressure drop and velocity of the air between coil fins are optimized, while fin and tube surfaces are kept clean, maximizing system heat-exchange efficiency and rate.”

Evaluating the best use of UV-C

UV-C can be used effectively by managers for most purification applications, says Larry Fletcher of RFG Environmental Group. Because of this, it is important to first define the installation’s goals — surface sanitation, air treatment, energy conservation/sustainability, etc.

Next, managers must determine where the system is going to be installed or used, such as in-duct, upper room, in room recirculation, or in the HVAC air handler.

“The installation location may impact the dwell time for the UV-C dose,” Fletcher says. “Utilizing UV-C requires delivering the appropriate dose to combat the microbes. The delivered UV-C dose is equal to the UV-C intensity multiplied by the dwell time. Every microbe has a different UV inactivation rate, which is the amount of energy required to break down its RNA/DNA structure, preventing it from reproducing.”

Jones says several operational conditions factor into the inactivation of pathogens:

- The target pathogen and its susceptibility to UV-C

- The amount of airflow in volume and velocity

- Air temperature and relative humidity

- The length of exposure time related to duct length

- Duct material reflectivity.

Each of these conditions factor into the amount of UV-C energy necessary in any given application. Installations are typically modeled to help predict individual dosage levels.

“UV-C dose is determined by the amount of germicidal energy necessary for a pathogen to be exposed to over a specific period of time,” Jones says. “In other words, UV-C dose is a function of time and intensity. Consider, for example, a surface-disinfection application involving cooling coils. The disinfection target (the coil surface) is stationary, so exposure or residence time is continuous. As a result, the UV-C intensity striking that surface can be relatively low. In the case of a moving air stream, however, exposure time is limited — a mere fraction of a second, in some cases — so UV-C intensity must be greater.”

For UV light to be effective, it must strike a pathogen for a sufficient length of time at the requisite power density to deliver a lethal dose for inactivating pathogens, Wang says.

“How UV lighting works as a disinfection technology depends upon the wavelengths being employed,” she says. “The UV-C band with a wavelength of 200-280 nanometers (NM) has emerged as a viable solution for interior settings due to its proven effectiveness against both bacteria and viruses.”

Approaches to consider

When evaluating a space for application of a UV disinfection solution, Wang says there are several UV-C-specific technologies for managers to consider.

An upper room air disinfection approach uses 254 NM UV-C lamps. The UV light is aimed toward the ceiling, helping to treat the air that is circulating through the room. Although the UV light addresses the circulating air above the occupants’ heads, it does not directly treat any of the surfaces below eye level in the space. While this technique does allow for the system to operate while occupants are present, it needs a ceiling height of at least 9 feet and preferably higher.

Additional caution during commissioning is imperative to make sure any occupants are protected against UV overexposure from either direct or reflected 254 nm UV-C light. This approach is generally less obtrusive than intense room disinfection, which uses 254 nm but is often more expensive on a per-square-foot in comparison.

The intense room disinfection approach uses pulsed xenon-based technology, which is a relatively new type of UV disinfection technology. This approach is not as obtrusive when not in use as similar-type solutions, since the technology fits more easily into various fixtures and spaces, Wang says. The pulsed xenon lamps have wavelengths of 200-1,000 nm, and they are exceptionally powerful.

“With the broadband coverage in UV-A, UV-B and UV-C bands and high output, pulsed xenon is very fast-acting, typically used in a 30-minute cycle time, against many pathogens,” Wang says. “Solutions that use pulsed xenon lamps can be considered for unoccupied spaces only.”

The third approach to UV disinfection incorporates the filtered far-UV-C light using the 222 nm wavelength in a continuous room disinfection solution. One primary difference in this approach is that laboratory studies suggest that filtered 222 nm far-UV-C does not pose a health risk for human eyes and show that this wavelength does not pose a health risk to human skin when used within appropriate parameters, which allows it to be applied throughout the day and night in occupied or unoccupied spaces for continual reduction of active pathogens.

This technology is continually powered while providing a continual dosing, meaning this technology application can be turned on and off every few minutes on a regular cadence to remain within published UV threshold limit value guidelines per American Conference of Governmental Industrial Hygienists guidelines, while providing ongoing active pathogen reduction, Wang says. Every 12 minutes, this type of UV-C light can be applied, and occupants can have the freedom to work throughout that space at any time of day or night.

The final approach is the luminaire onboard air disinfection technology, an offshoot of the 254 nm upper room solutions that provide a more targeted approach and can be used in lower ceilings. It uses an enclosed fixture to take in air from the surrounding area and run it through its own filtration with a 254 nm lamp with UV emissions fully contained inside. The luminaire then pushes that treated air back into the room.

This approach is more localized to where pathogens are potentially introduced into a space compared to an in-duct HVAC system. So it is able to treat the air and turn it over numerous times per hour in the space where the occupants are located. Occupants are not directly exposed to the 254 nm wavelength in this solution, and there is no concern of material photodegradation that might result from UV systems. [Text Wrapping Break]

On the horizon

LED UV-C systems are starting to come on the market, Fletcher says. The limited energy output of UV-C LEDs requires either long exposure times or that the microbes come very close to the surface of the LED or both.

“Additionally, UV-C LEDs are expensive when compared to traditional UV-C lamps,” Fletcher says. “However, we do anticipate UV-C LED technology will begin to make inroads into the air treatment market over the next several years as the technology evolves and prices come down.”[Text Wrapping Break]

UV products based on other wavelengths, including 222 nm and the blue light range of 405-420 nm, have come out in the last year, Fletcher says, as these wavelengths have shown germicidal properties.

“222 nm UV-C is a very promising lamp technology that is considered to be potentially less harmful to both skin and eyes,”Fletcher says. “However, there is limited antimicrobial testing at this time, and the lamps are expensive compared to traditional UV-C lamps. “The 405-420 nm range has also been shown to be antimicrobial at significantly higher energy, typically in the range of 100s to 1000s of Watts versus microwatts for traditional UV-C lamps.”

The design of a UV-C air treatment system will be determined by the type of system being considered and the installation location.

“The best approach is to get the UV-C system manufacturers involved,” Fletcher says. “They can provide assistance in determining the correct configuration, associated installation layout and identify potential challenges.”

Maura Keller is a freelance writer based in Minneapolis, Minnesota.

Related Topics: