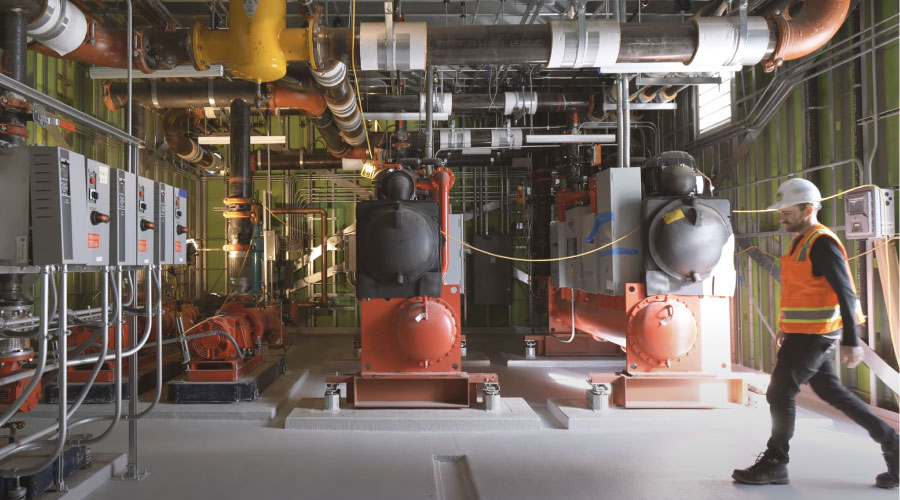

Mechanical systems account for about 25 percent of total water use when they operate properly, but equipment failures and improper setup can increase this number dramatically.

Mechanical systems account for about 25 percent of total water use when they operate properly, but equipment failures and improper setup can increase this number dramatically.Water Watch: Strategies for Conservation

Water audits, leak-detection technology and updated fixtures can help managers curtail facility water use

How widespread are water leaks in institutional and commercial facilities? The WaterSense program estimates that on average, leaks account for more than 6 percent of a facility’s total water use. Water has long been the forgotten utility. It was inexpensive, and most thought is was plentiful. Beyond that, facilities had few incentives to conserve water.

That time has passed. Population growth, economic development, aging infrastructures and ongoing regional droughts are causing trouble for municipal water systems trying to keep up with rising demand. Maintenance and engineering managers are facing rapidly rising rates, water use restrictions or both.

The good news is that facilities with comprehensive water-conservation and leak-detection programs have found that the return on investment is becoming easier to justify. To achieve savings, managers need a program designed to address all aspects of water use and leaks within a facility.

Leaks and audits

A growing number of managers are implementing leak-detection technology, in some cases incorporating WiFi technology, that sends email alerts when a detector comes in direct water contact. The systems also sound a loud alarm and flash red LED lights to alert technicians of the leak.

Water use audits, like their energy counterparts, also are important in understanding a facility’s water use and what can be done to reduce it. They trace water use from its point of entry into the facility through its discharge into the sewer. They identify each point of water use in and around a facility and estimate the quantity of water used at each point. They identify and quantify unaccountable water losses and possible leaks and provide technicians with a road map to potential savings.

A comprehensive water-use audit should examine all major areas in which a facility uses water, including sanitation, plumbing, mechanical and irrigation systems. For each of those areas, the audit provides a breakdown of the how, when and where of water use.

In addition to identifying all water-use points and flow rates, the audit should identify if the water used is hot or cold or if it undergoes special filtering or treatment. Reducing water use in applications that use hot or treated water produces savings that go beyond the cost of the water.

When completing the inventory, managers need to pay attention to any unexplained water flow. As piping systems are modified, it is easy to lose track of what piping serves what equipment. Managers should not be surprised to find water flowing to equipment that is no longer used.

Related Topics: