Mechanical systems account for about 25 percent of total water use when they operate properly, but equipment failures and improper setup can increase this number dramatically.

Mechanical systems account for about 25 percent of total water use when they operate properly, but equipment failures and improper setup can increase this number dramatically.Water Watch: Identifying HVAC Culprits

Water audits, leak-detection technology and updated fixtures can help managers curtail facility water use

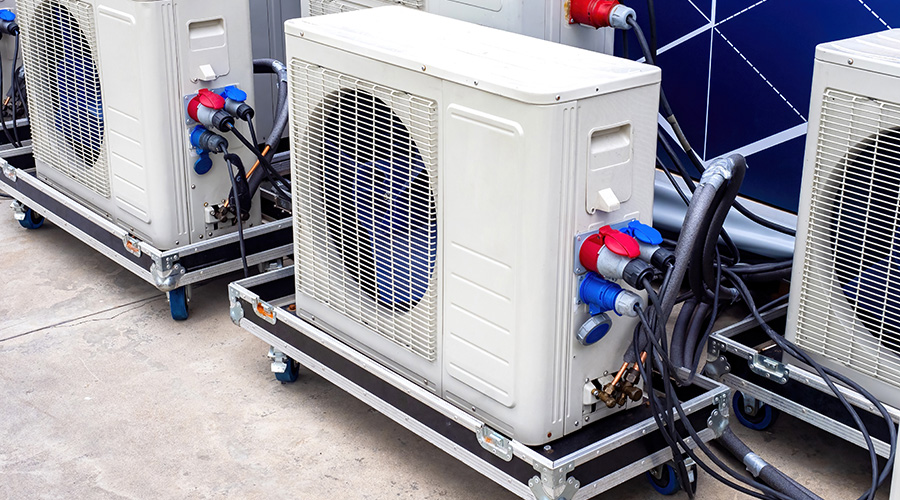

While most of the attention in water-conservation and leak-detection programs goes to reducing the amount of domestic water a facility uses, mechanical systems often offer the highest rate of return for retrofit programs. In a typical facility, mechanical systems account for about 25 percent of total water use when they operate properly. But equipment failures and improper setup can increase this number dramatically.

To determine the potential savings of a retrofit program, technicians need to identify each component that regularly uses water, including boilers, cooling towers, and once-through refrigeration-cooling systems. For each system, they need to measure water use.

For cooling towers, technicians need to bleed off water at a certain rate to prevent the level of suspended solids from exceeding the manufacturer’s recommended level. They also must add water to the system to replace water lost due to drift from the tower.

The system should monitor losses and solids and then bleed off the correct amount of water, but that rarely happens. Bleed rates typically are set too high, or the makeup valve malfunctions, and too much water is added to the tower basin. The result is higher water use by the system.

Boilers also require bleeding off water to prevent solids from accumulating. A bleed rate that is too high results in wasted water.

For both cooling towers and boilers, technicians need to inspect the operation of makeup and bleed systems and look for obvious equipment failures. They should test the water in both systems and measure the rate at which water is added. If they can reduce water rates — particularly by adding automated monitoring systems — they can determine the amount of water the changes can save in a season.

For refrigeration systems with once-through cooling systems, technicians can identify the equipment the systems serve and the capacity of the installed systems. For each, they can measure the flow rate through the cooling system and determine the amount of time the flow occurs to estimate potential water savings. Even when these systems operate properly, they use large amounts of water. Malfunctions, such as valves that fail to close when water is not needed, make matters even worse.

Related Topics: