Water Heater Upgrades Improve Energy Efficiency at Quinnipiac University

University realizes financial savings after installing new water heater system in sports arena.

The financial savings continued after the units were installed, Marquardt says. The two water heaters easily met the building’s hot water demand and provided an efficient system that improved health and safety. The solution also saved space and energy and reduced the campus’s carbon emissions.

"We also had to have mixing valves to deliver 120-degree water to the stadium with the old system," he says. "Now we don't have to do that because the temperature leaving the water heater is always 120 degrees."

When water is needed, the modular units also work together to share the load. So instead of one unit supplying 100 percent of the water, one unit might provide 40 percent and the other 60 percent. Marquardt says this process guarantees a constant supply of hot water.

"Because they are paired together, we never have one of them running at 100 percent," he says. "Dropping the load on each raises their efficiency."

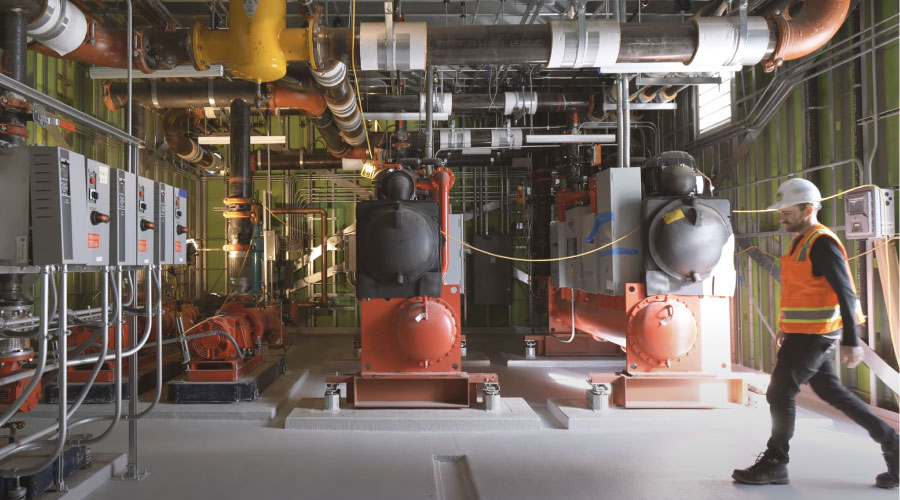

The two systems, which at 34 inches wide take up less room in the mechanical room, were also easy to install, Marquardt says, adding there are two flanges on the back of each unit — one for hot water and one for cold water — and a natural gas hookup.

"The design makes it really easy to bring a pipe to it and connect it to the flange," he says. "It was a nice and neat installation. Most installations of these water heaters only take a day or two."

The new system's only drawback is a cooler mechanical room.

"The units are closed up, so they don't throw off any heat," he says. "But while the room is colder, it is not cool enough that we need supplemental heat. But think of the savings. We were losing a lot of heat with the old system."

Spotlight on maintenance

The new hot water heater system requires far less maintenance than the old boiler hot water system. In the past, technicians had to maintain the mixing valves that kept water at the correct temperature.

"We had a lot of issues with mixing valves," he says. "Because mixing valves are no longer required, we no longer have that maintenance need."

Marquardt says each one of the hot water heater's three engines (250,000 Btu) are independent, meaning "each engine has its own gas valve, igniter, inducer and circuit board. So if one engine goes down, the other engines pick up the slack. They only share a common flue and hot/cold header."

The old system's maintenance also included its 1.6-million Btu power flame burners.

"We had to have someone come out, clean the system, check the igniter and sensors and do a combustion check annually to keep the burners clean and running efficiently,” he says. “We don't have to do that anymore.”

Marquardt says he found the reduced maintenance appealing, but what really sold him on the system was the way the supplier tackles the problem of outdated parts.

“Each engine has its own inducer, gas valve and ignitor, but the cool thing is all these parts are interchangeable,” he says. “I can just keep one of each part — one gas valve, one inducer, one igniter — and it'll work with any hot water heater. I won't have to stockpile a bunch of parts that become useless later on when the systems change. Whether it's a boiler, a water heater, or a light fixture, I've seen parts we can't use anymore just sitting on shelves. Nobody wants to deal with outdated parts. Now, I can keep the parts on hand and have fewer of them in stock."

The upgraded hot water system at M&T Bank Arena continues to drive improvements to the university's other buildings.

Marquardt and his team have discovered that replacing outdated, inefficient storage tanks with on-demand water heaters can significantly enhance energy efficiency and reduce costs. The systems deliver hot water instantly, cutting energy waste. The shift also boosts efficiency, saves valuable space and eliminates costly maintenance tasks, such as managing mixing valves.

The university plans to expand this technology across its three campuses, and the new system conserves energy and supports health and safety. The reduced maintenance and modular design, along with the longevity of interchangeable parts, ensure a reliable and future-proof application to meet the university's water heating needs.

Ronnie Wendt is a freelance writer based in Minocqua, Wisconsin.

Related Topics: