Understanding Advanced Filtration in Air Handling Units

Advanced filtration, combined with new diagnostic tools and the WELL rating system, are valuable strategies for fighting the coronavirus in indoor spaces.

Viruses vary in size. The average coronavirus particle is 0.12 microns (μm) with a size range between about 0.002 to 2.5 μm.

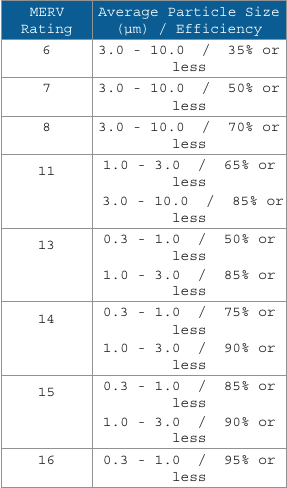

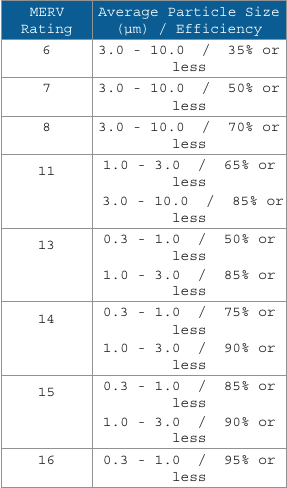

AHUs contain filters that remove particulates from the airstream. Varying filters have different efficiencies when filtering different particulate concentrations and sizes, and ASHRAE has a standard reference for Minimum Efficiency Reporting Value, or MERV rating for filters:

Source: ASHRAE Standard 52.2-2019

Beyond MERV 16, HEPA, and Ultra Low Particulate Air (ULPA) filters are rated for even smaller sized particles and typically remove at least 99.9995 percent of dust, pollen, mold, bacteria, as well as viruses with a size of 0.12 μm. Conversely, higher efficiency filtration has the potential to increase energy use, and make a system fan draw air less efficiently, so other forms of air treatment might involve more investigation such as pre-filters, UVC, and Bipolar Ionization (BPI) for handling smaller particles and aerosols. Only a qualified engineer and environmental testing team should assess and recommend modification.

To understand infectious aerosol movement, ASHRAE identifies that the management of indoor air to control the distribution of aerosols is critical. New technology simulates this condition with completely safe DNA particles — these are the same size particles as SARS-CoV-2 — to approximate viral movement in a building's air systems and surroundings to assess potential risks.

This technology also allows for testing room dynamics, answering key questions such as how long it will take a virus from an infected individual to disperse in an enclosed space (i.e. conference rooms, auditoriums) to a non-infectious level. Testing using this technology provides data to determine the most effective mitigation combinations of different technologies.

Combining this new technology with diagnostic tools, as well as the WELL rating system and an ongoing data-driven air-monitoring system, provide facility managers with a holistic approach for safe indoor air quality, and this synergistic approach can be a valuable long-term consideration for facility managers to demonstrate optimal building performance. Continuous monitoring with air quality sensors throughout a building provides valuable data to facility teams by capturing real-time issues as they occur, allowing the onsite facility team to immediately respond, thereby minimizing health risks and limiting exposure at the property.

Kathy Collins, AIA, WELL AP, (Kathy.Collins@NV5.com) is sustainability director at the international engineering company, NV5 Global, Inc. She has more than 20 years of experience working with asset and operations teams, optimizing high-performance buildings.

Related Topics: