The Importance of Scheduled Boiler Inspections

Preventive maintenance tips for water-side and fire-side boiler

By Mike Valentino, ABMA Technical Consultant

A well-maintained boiler can pay facility owners large dividends over the typical life of a boiler ranging from 20 to 30 years — even longer with a sound preventative maintenance program in place.

The need for proper care and preventive maintenance of a boiler or multiple boiler system cannot be overstated. Conversely, improper care can result in higher operating costs, frequent breakdowns and outages, and costly replacement and service work.

A boiler system is comprised of many key elements, including:

- The boiler pressure vessel

- Burner and fuel delivery systems (for fossil fuel-driven boilers)

- Combustion controls and related safety systems

- Feedwater system/deaerator

- Water chemical treatment system and softeners

- Instrumentation including pressure-temperature gages and monitors

- Flue gas heat recovery economizer (if present)

- Stack draft control system (if present)

- Plus, a litany of subsystems and components including: valves, dampers, annunciators, flow meters, and more.

The list is far from exhaustive and dependent on boiler-boiler design, function, and operational characteristics. Through development of a “check list” consisting of preventative maintenance inspection points, inspection frequency, and assignment responsibility, expectation for long boiler service life at optimal performance can be realized.

Water-side inspection and maintenance

When speaking of boiler maintenance, it is referring to two general areas: “water-side” and “fire-side.”

Boilers are largely composed of steel. In a watertube style boiler, water to be heated or converted to steam flows through tubes joined by an upper and lower drum. Hot flue gases from combustion surround the tubes and drums, and transfer its heat to the water to generate hot water or steam.

In a firetube style boiler, water surrounds a steel furnace section and tubes which contain flowing hot gases. Heat is subsequently transferred from the hot gases to the cooler surrounding water.

These steel-based materials are subject to corrosion from the water which contains oxygen and impurities. Maintaining proper water chemistry is key to maintaining the integrity of these materials and extending the boiler life. Boiler water and feedwater quality are two very key aspects to boiler performance and longevity. Poor quality can lead to scale forming deposits, corrosion, and poor steam quality.

The American Boiler Manufacturers Association (ABMA) provides recommendations on limits for boiler water and feedwater quality, for both firetube and watertube boiler designs operating at various pressures. This very detailed document titled “Boiler Water Quality Requirements and Associated Steam Quality for ICI Boilers” may be purchased from their website.

Feedwater limits include:

- Dissolved Oxygen (ppm)

- Total Iron (ppm)

- Total Copper (ppm)

- Total Hardness (ppm)

- pH

- Non-volatile Total Organic Compounds (ppm)

- Oily Matter (ppm)

Boiler water limits include:

- Maximum Boiler Water Solids (ppm)

- Steam/Boiler Water TDS (total dissolved solids), ppm

- Maximum Total Alkalinity, expresses as CaCO3 (ppm)

- Maximum Suspended Solids (ppm)

- Maximum Fractional Carryover (FCO)

Boiler feedwater should be softened for low pressure boilers and demineralized for high pressure boilers. It must be free of oxygen, and essentially free of hardness constituents and suspended solids.

Additionally, regularly scheduled boiler blowdown is an important preventative maintenance procedure and should be performed regularly to reduce TDS levels.

As a real-life example of boiler water quality negligence, a service agent was recently called in by the facility supervisor because their boiler was no longer servicing its intended load. The photograph depicts the reason why the boiler was having trouble.

This unit, a watertube boiler, had been operating over the past one and a half years bypassing the water softener, without water treatment, and ignoring a regularly scheduled blowdown schedule. Scale developed inside the tubes where the boiler water flowed and had built up to a point where the hot flue gases could no longer effectively transfer its heat to the water.

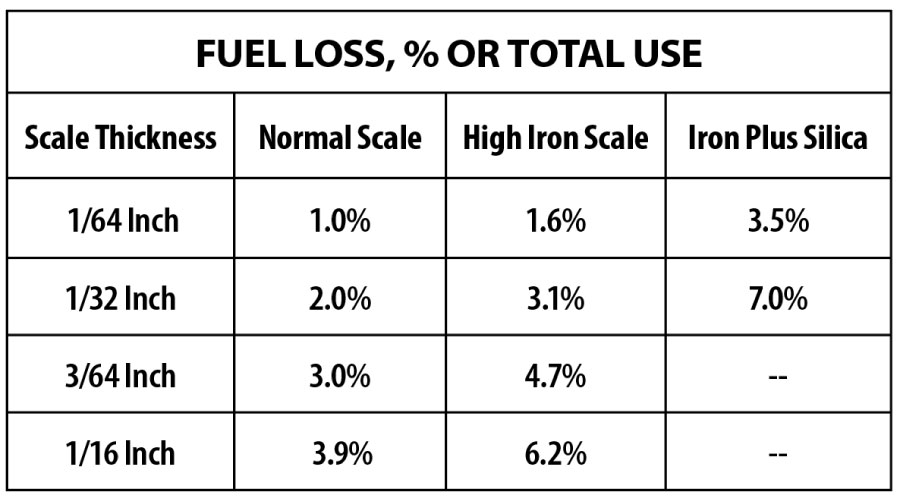

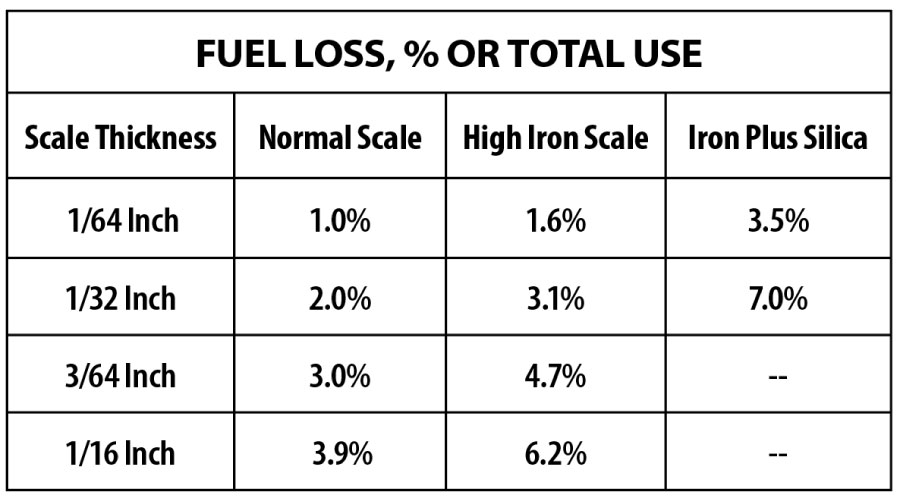

The “National Institute of Standards and Technology Handbook” provides these estimates of Fuel Loss based on scale deposit thickness:

It is recommended that the water softeners and chemical feed systems be inspected monthly, at a minimum, by an operator to ensure proper operation and dispensing of required chemicals. More frequent inspection will depend on initial feedwater chemistry, boiler usage and type.

There are other key components to the water-side of boilers, such as the boiler water level controls, the feedwater pumping systems, and other controls that require regular inspection and maintenance.

Fire-side inspection and maintenance

The fire-side to the boiler includes those surfaces exposed to flame and hot flue gases, as well as components and other systems required to produce the necessary heat required to heat water and make steam.

Most boilers today fire natural gas as their primary fuel, however there are still a number of boilers that use fuel oils, LP gas (propane), even renewables such as landfill and digester gases as their primary or auxiliary fuel source. While there are different definitions to boiler efficiency including combustion and thermal efficiency, to the operator-owner the bottom line comes down to fuel utilization and operating costs, i.e., how much fuel and dollars are required to manage my building heat or process demands.

Paramount to good efficiency is the burner. A well-operating burner will deliver the fuel’s available heat in the most efficient and cleanest manner subject to the burner’s capabilities and the application at hand. Poor combustion can lead to unwanted carbon monoxide (CO), lower combustion efficiencies, and even “sooting” of the fire-side surfaces. These inefficiencies increase costs and potential for early failure. Soot formation on the fire-side, much like scale on the water-side, impedes heat transfer from the hot gases to the medium being heated.

Excess air, for example, is defined as the additional air required above the theoretical minimum required to exactly convert the fuel into CO2, H2O vapor, and N2 from the combustion air. This is called “stoichiometric” air. For the purpose of this article, minor flue gas constituents such as NOX compounds produced during combustion are ignored.

In reality, combustion air in excess of stoichiometric air is required to ensure low levels of CO and unburned hydrocarbons that may result in the combustion process. Most well-tuned burners firing natural gas, for example, will operate with approximately 15 percent excess air from mid-to-high fire. At lower firing rates, particularly with high turndown burners, even more excess air is required to provide the proper mixing of air and fuel at lower rates. As excess air levels are increased, resulting combustion efficiency is reduced due to the cooling of the flame — ultimately resulting in additional fuel required to satisfy the hot water or steam demand.

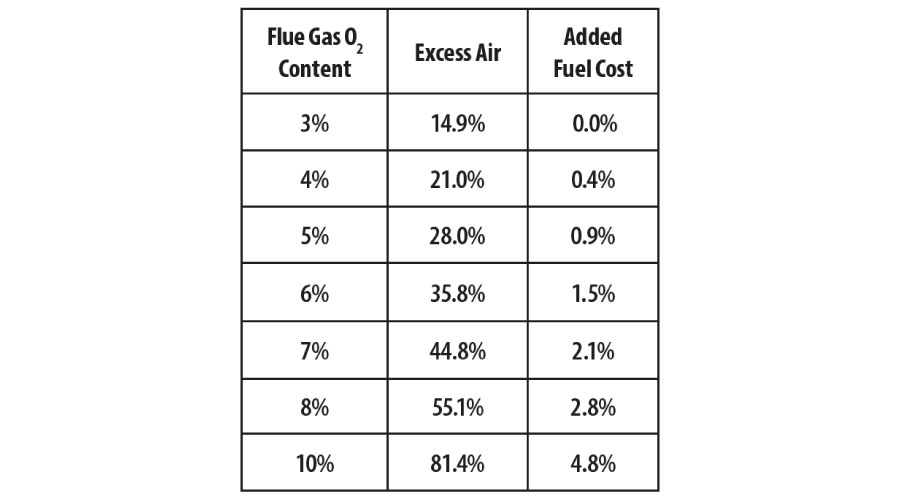

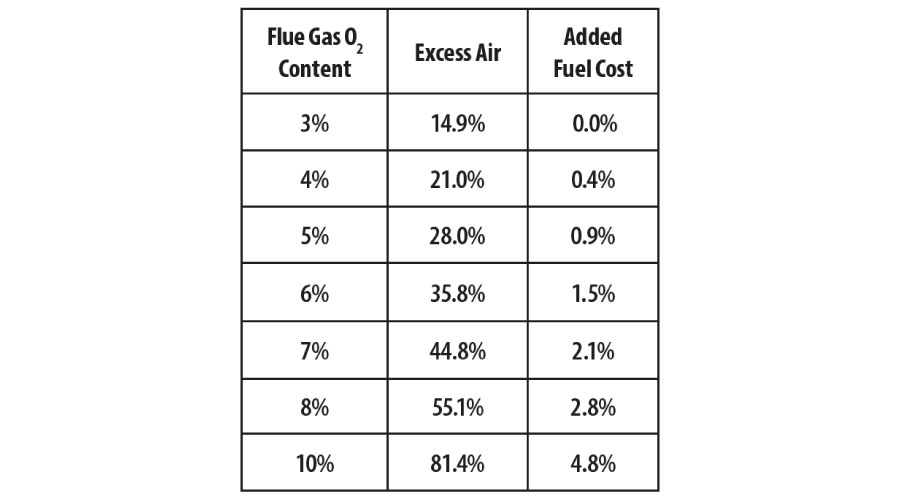

As a guideline, the following table provides an estimated added fuel cost firing natural gas at vairous excess air levels. A value of 3 percent O2 (oxygen) in the boiler flue gas stack serves as the baseline:

Results are similar firing other fuels such as fuel oil, LP gas, digester/landfill gases, and others. Burner linkages should be routinely checked for wear, looseness, and repeatability. Burner internals should also be examined periodically for wear and material deterioration, fatigue and cracking.

Often it is financially prudent to upgrade legacy burner controls. For example, linkaged burners can exhibit hysteresis and non-repeatability leading to off-ratio burning of fuel. A “parallel positioning system” upgrade from linkages can offer fuel savings of in the range of 5 to 15 percent alone.

There are many additional systems and components associated with the burner and its operation. This includes the fuel delivery system, gas pressure regulation, burner sequencing, flame monitoring, and associated safety all requiring routine preventative maintenance.

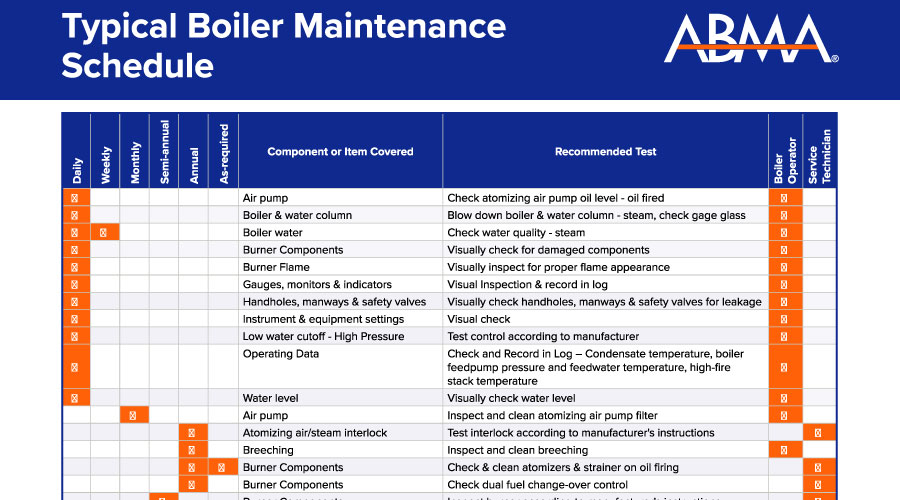

ABMA recommended boiler maintenance schedule

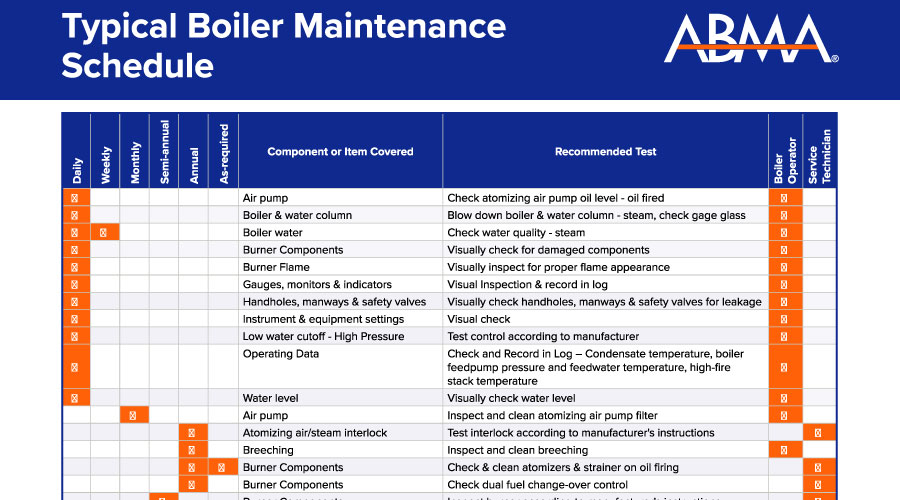

ABMA has produced a typical boiler maintenance schedule outlining touch points and recommended tests, inspection frequency, and qualified individuals performing these duties. The free document can be found at www.abma.com/boiler-maintenance-schedule.

In many instances, maintenance and preventative maintenance duties can be performed by the boiler operator. With others, it’s recommended that an experienced and qualified third-party service agent perform both inspection and maintenance.

The schedule highlights 54 of the most common inspection and maintenance points, a suggested frequency of inspection (Daily, Weekly, Monthly, Semi-Annually, or As-Required), as well as who should perform the work.

Several excerpts from the publication include:

- Boiler and Water Column. Check Daily: Blow down boiler and water column, steam, check gage glass — Performed by Operator

- Low Water Cutoff, High Pressure. Check Daily: Test control according to manufacturer — Performed by Operator

- Low Water Cutoff, Low Pressure. Check Monthly: Test control according to manufacturer — Performed by Operator

- Water Level. Check Daily: Visually check water level — Performed by Operator

- Burner Components. Check Semi-annually: Inspect burner according to manufacturer’s instructions — Performed by Service Technician

- Fuel-air-ratio Controls. Check Annually and As-Required: Tune burner for CO, excess air, and emissions requirements — Performed by Service Technician

In most states, power boilers require an annual inspection by the State Boiler Inspector at least once per year. For high-pressure steam boilers (boilers operating above 15 psig in pressure), internal inspection of the pressure vessel is typically required by state code, by a boiler insurance provider, or by the local authority having jurisdiction. Inspection dates and outcomes should be documented in the boiler logbook, noting any issues or deviations from normal.

Periodic review of the logbook can indicate trouble brewing within the boiler system early on, before small problems become major ones. Performing regularly scheduled preventative maintenance while attending to potential issues will assure maximum boiler uptime, fewer unscheduled downtimes, and operation at peak efficiencies.

Mike Valentino is a technical consultant for the American Boiler Manufacturers Association (ABMA).

Since its founding in 1888, the American Boiler Manufacturers Association (ABMA) has advocated for the safe production and operation of boilers, facilitated advances in energy efficiency, and provided solutions for our member companies. To learn more, visit ABMA.com. Next May, ABMA will be hosting BOILER 2024 — the only two-day world-class expo and conference for the boiler supply chain, bringing together boiler manufacturers, influencers, and end-users of our products to collectively seek out best practices and solutions to industry challenges. For more details, visit BOILER2024.com.

Related Topics: