Temporary Cooling Systems: Managers Have Many Options

To a large extent, the load requirements and the power and space limitations of the application will determine the type of temporary cooling equipment managers specify. Even then, managers have options when it comes to selecting a particular system.

For small, localized applications, the portable system is the most common temporary cooling system. Portable systems come mounted on wheels and are easy to move, and most units are small enough to fit easily through a doorway. They are fully self-contained and typically plug into a standard 120- or 240-volt outlet.

Flexible ducts connected to the units allow technicians to position them to direct the cooled air where it is required. An additional flexible duct allows heat rejected from the unit to flow from the space. Units are available with cooling capacities of up to 5 tons.

Larger cooling loads require units located outside of the conditioned space. These units can be self-contained, with flexible ductwork supplying the cooling air to the conditioned space, or they can be split systems, with a separate cooling coil and circulation fan installed within the space.

The capacities of these units typically range up to 100 tons, and most are air-cooled. The units can be mounted on a trailer or pad. Determining the type of unit best suited to an application depends on the accessibility of the space and its distance from the building's exterior.

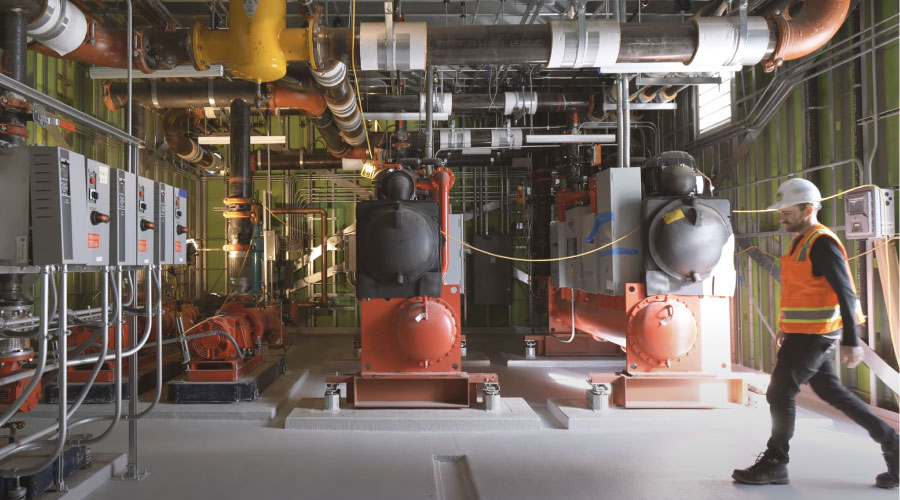

Managers also can opt to bring in still larger pieces of equipment that provide cooling for entire buildings. Typically, they are self-contained, with either cooling towers or air-cooled condensing units to reject the heat from the units. Because of their larger capacities, most of these components are designed to supply chilled water to the facility.

Connecting these units to the building's chilled-water distribution system requires the installation of temporary piping. Technicians also will have to route electrical power to the unit or make arrangements for a temporary electrical generator. Again, electrical power supplied to the unit must match the unit's power requirements. Managers can reduce installation time by scheduling the installation of connection ports, valves, and electrical connections in critical systems ahead of time.

Related Topics: