Taking Inventory of Safety Relief Valves

Safety relief valves are designed to ensure that whatever they connect to does not blow up. All mechanical systems that involve heated liquids or gases, such as hot water and steam, or pressurized gases, such as compressed air, have safety relief valves that protect for unplanned conditions. Examples of such situations include:

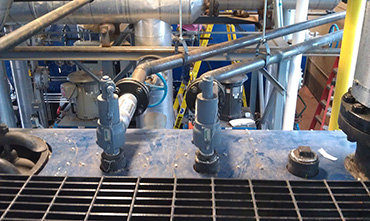

High-temperature water application with expansion joint at the outlet.

High-temperature water application with expansion joint at the outlet.

- A key component — such as a sensing, logic, or control device — involved in the control of the amount of heat or pressure in a system can fail.

- An operator can accidentally trap fluid in a heat exchanger, such as when performing maintenance and leaving the valves shut.

- An explosion can occur during a fire, which is the last thing emergency personnel need to worry about.

The safety relief valve is not involved in the normal control of the system. Rather, it is waiting in the wings, ready to jump into action when something goes wrong. If something does go wrong and the valve is not in place to do its job, the situation will be worse than any horror movie.

Take inventory

The first step in maintaining a system's safety relief valves is taking inventory. Technicians should make a list of all safety relief valves. The failure of a half-inch safety relief valve can result in enough damage to make the newspapers and bring on the lawyers. Keep this list active and available to all applicable personnel.

Label each valve — if it is not already labeled — so everybody can positively identify it. Record which tank, pipe, heat exchanger or other equipment it serves.

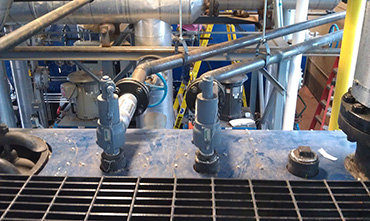

High-pressure steam boiler with multiple relief valves and drip-pan elbow.

High-pressure steam boiler with multiple relief valves and drip-pan elbow.

Record the set pressure. If the system pressure is higher than the set pressure of the relief valve, you have a big a problem that technicians need to address immediately. If the valve label is missing, painted over, or illegible, get a new valve.

Record the rated flow, list the reason the safety relief valve was installed, and the way it is supposed to function. For example, when it relieves, is it supposed to blow a great deal or little? Is it in place to protect a vessel when there is an external fire, to protect lower-pressure rated equipment downstream of a pressure-regulating valve or to protect from the controls of a boiler running away? If you cannot answer any of these questions, call the original design engineer. Knowing the valve' purpose helps operators better understand their systems, identify problems, and troubleshoot them. Engineers often will install a safety relief valve for a specific condition, so it is imperative that operators understand the reason so they can take care of it.

Record the system's normal operating pressure or pressure range. If the relief valve vents into a pressurized system such as a return system, record that normal operating pressure or pressure range.

Related Topics: