Specifying HVAC Equipment Based on Facility Needs

With careful planning, upgrades of boilers, chillers and air-handling units can improve efficiency, comfort and savings

ll building HVAC systems have a finite service life. Even with a comprehensive maintenance programs, systems and components will eventually wear out, ongoing maintenance costs will increase, system reliability will slip, and operating efficiency will decrease. Managers might be able to keep things running for a while, but eventually, the system will have to be upgraded. When that happens, how well the manager plans that upgrade project will determine to a great extent the program’s short-and long-term success.

Managers should not undertake an HVAC system upgrade lightly because such projects present too many challenges. HVAC systems have long service lives. Installing the wrong system or installing the correct system improperly will result in problems managers will have to live with for years.

HVAC systems also are expensive, so money spent on system upgrades must be spent wisely, or managers might have to go through the process again. The process of upgrading an HVAC system also can be disruptive to occupants and operations, so it takes careful planning and scheduling to minimize such disruptions.

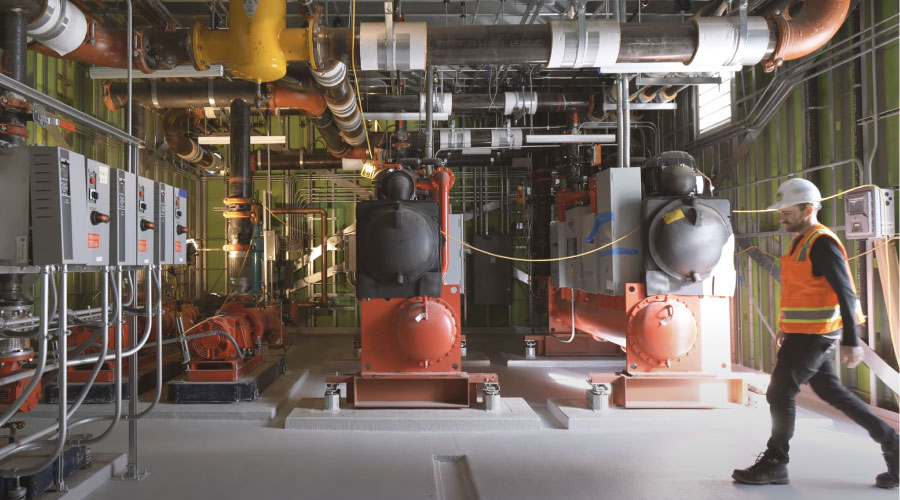

While careful planning is necessary for most HVAC system upgrades, it is particularly important when considering the upgrade of three essential systems; boilers, chillers, and air-handling units. By addressing key issues in each of these upgrade areas, managers can get the maximum performance out of their new systems.

Hot topic

The first issue managers need to address when considering a boiler upgrade is the constraints of the existing installation. Boiler room space generally is limited. Is there sufficient room to install the upgraded boiler or boilers? Changes to building systems over the years might make it difficult to install the new boilers without making modifications to piping, flues, ventilation systems, and other equipment.

Is there an adequate, clear path to get the boilers into the boiler room from outside the building? In many cases, the boilers might have been installed before the completion of boiler room walls, making it necessary to remove portions of walls to remove the old boilers and install the new ones. These size issues will require managers to carefully consider options when selecting new boilers.

Timing also might be an issue, since most upgrades take days to weeks. If the boiler is used only seasonally, then managers can schedule replacement scheduled during the off-season. But if boilers are needed year round, a temporary installation might be required and must be planned for.

A second issue managers must address early in the upgrade planning process is the boiler’s capacity. Even if the original boiler was properly sized for the application when it was installed, that might no longer be true. Boilers have service lives of as long as 40 years. Over this period, many changes have taken place to the operations and activities taking place in the space, as well as to the building envelope, that require different heating loads.

If the new installation is to meet the needs of the facility, managers need to consider the current and future demand for heat from the boiler. If the load varies over time, consider installing several modular boilers that operators can stage to meet the requirements of the facility. Matching the available capacity of the boiler to the demand increases the efficiency of the operation.

A third issue managers must address if the upgrade is to succeed is understanding other changes to accommodate the upgraded boilers. Is asbestos present on the piping systems that installers must addressed? Does other equipment, such as expansion tanks or system pumps, also require upgrades? Ignoring these issues will prolong the upgrade process and increase costs.

Related Topics: