Retrocommissioning: Finding Energy Waste

Retrocommissioning can uncover problems with systems and components that require adjustment or repair.

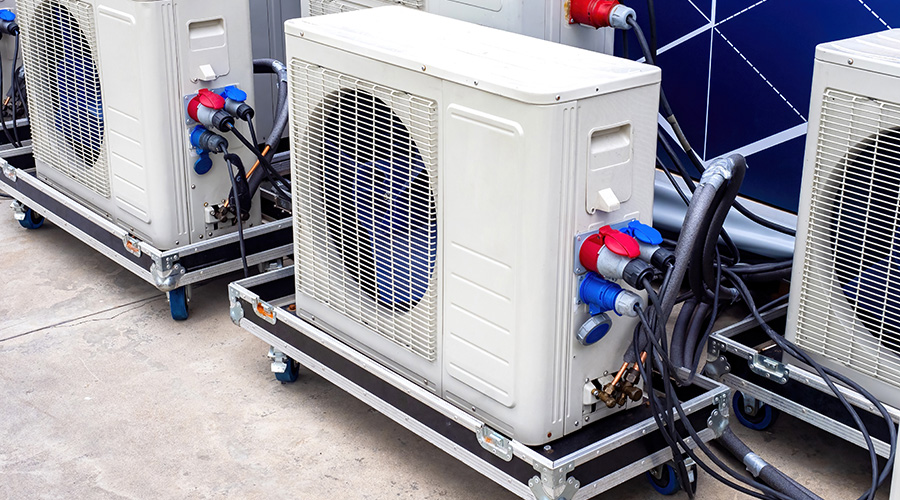

The retrocommissioning process gives inspectors, along with maintenance and engineering managers, the ability to investigate all areas, activities and processes within institutional and commercial facilities. The goal of the process is to match HVAC system performance to the needs of the organization and building occupants. Along the way, it also can uncover problems with systems and components that require adjustment or repair.

Among the typical issues I would find during retrocommissioning projects are these:

- abandoned exhaust systems still operating

- abandoned piping still on and discharging to the drain

- abandoned ductwork left open and discharging air to void spaces

- ductwork not connected to diffusers

- extremely dirty filters

- dirty internal ductwork

- non-operational exhaust fans

- equipment supplying unoccupied areas that eventually were put on a schedule

- non-operational ampers not operating

- outdated controls

- windows left open in the winter because there was no control for the radiators

- variable air volume units (VAV), package terminal air conditioners, and fan coil units out of calibration

- VAV units working in reverse

- return-air fans running backwards

- uninsulated steam and condensate piping

- supply systems connected to exhaust systems and exhaust systems connected to supply systems.

— Phillip McCrory

Related Topics: