Renovations Present Opportunities for Energy-Efficiency Improvements

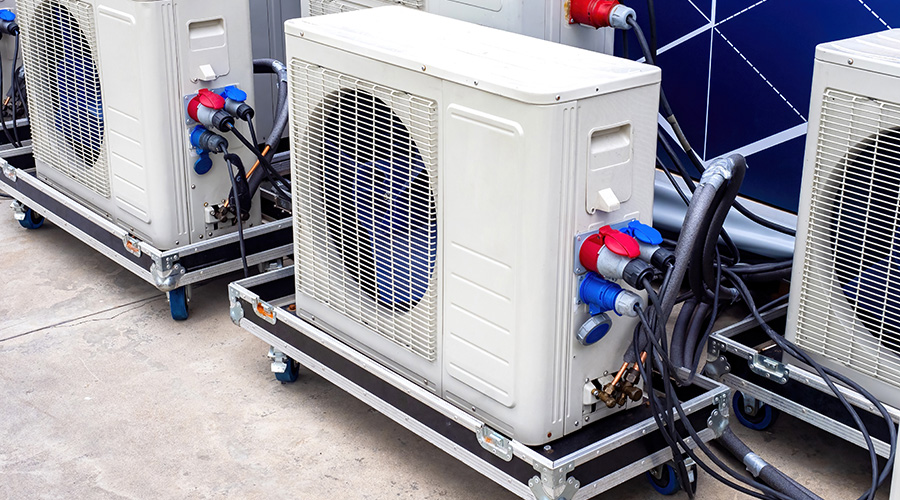

Energy once again is a major issue for engineering and maintenance managers. HVAC systems generate an estimated 25 percent of the total energy use in commercial and institutional buildings, so improvements in energy efficiency can result in significant financial savings.

The first step managers need to take in reducing energy use is to ensure all energy-using systems are performing as efficiently as possible. This action is particularly important in large energy-using systems, such as building chillers and boilers, where even a slight increase in operating efficiency can translate into significant annual savings.

Managers should review all energy-using systems for proper operation. They also should check maintenance records to determine technicians have performed maintenance activities properly and at the correct intervals.

Evaluating Equipment Options

While ensuring building systems operate as efficiently as possible is one key tactic for reducing energy use, managers eventually face decisions related to replacing or upgrading existing systems and components. New building construction, major building renovations, and system or component replacement offer managers opportunities to specify and install systems and components matched to the application requirements, while obtaining the highest possible energy efficiency at the same time.

But many options exist when it comes to specifying equipment for new construction, renovation, or equipment replacement, so managers need to ask key questions during the decision-making process. Not all new systems and components offer the same level of performance or energy-efficiency benefits — even though they might have identical capacity ratings — so specification decisions become even more difficult.

Different manufacturers also might have used different testing procedures when rating the performance of their products, so the performance and the capacity of the equipment might not be consistent.

Even the slightest disparity in testing procedures can produce a major difference in a product’s capacity or efficiency ratings. Manufacturers that use different testing procedures are not trying to cheat or stack the deck in their favor. They might have very good reasons for conducting the testing in a particular fashion.

But different test procedures mean managers are not comparing apples to apples when evaluating HVAC system and component options. Different capacity and efficiency ratings could be the result of different testing methods.

How then can managers make comparisons between different products that may or may not have been rated the same way?

Related Topics: