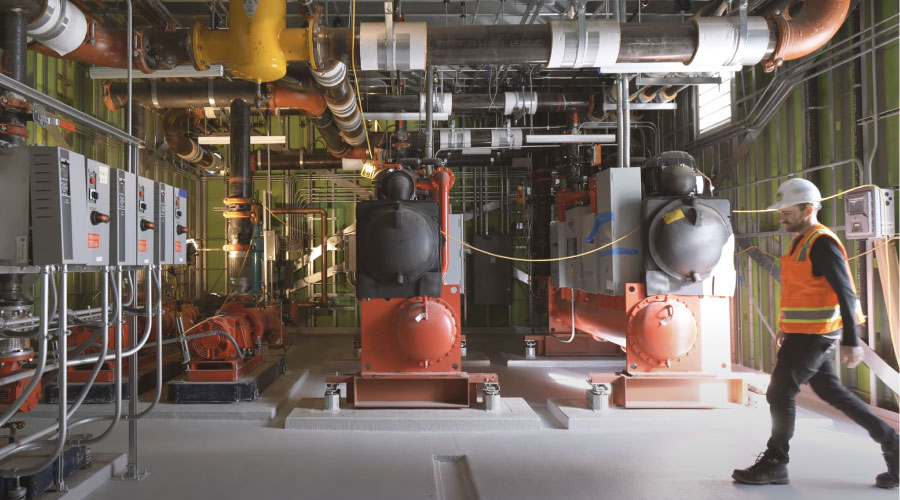

Regular Inspections, Testing Helps Improve Energy Efficiency in Chillers

Energy efficiency and HVAC system reliability remain top priorities for maintenance and engineering managers. Chillers are the single largest users of electricity in most institutional and commercial facilities, as well as the most expensive piece of equipment in HVAC systems. So they are natural targets for improvement efforts. While many managers look to chiller retrofits, system add-ons, or even replacements to improve efficiency, many overlook the single most important factor in determining both chiller efficiency and reliability: maintenance.

The lack of proper maintenance has a detrimental impact on these goals. It quickly decreases the service life of the chiller by 25-50 percent, and system reliability declines.

The lack of maintenance also results in increased energy use — sometimes doubling it in just a few years. Even though front-line technicians are not performing required maintenance tasks, overall maintenance costs increase because of the resulting early component failures and service interruptions.

The bottom line is that for every $1 invested in chiller maintenance, managers can expect a return of $10 dollars in the form of reduced operating costs and fewer breakdown maintenance repairs.

Facilities with new, high-efficiency chillers are at even greater risk. Advances in control systems, refrigerants, and chiller designs over the past 20 years have resulted in vast improvements and chiller efficiencies. But these improvements also have resulted in tighter operational tolerances, which have made regular and preventive maintenance more important than ever. Ignore maintenance on these units, and their benefits rapidly disappear.

Related Topics: