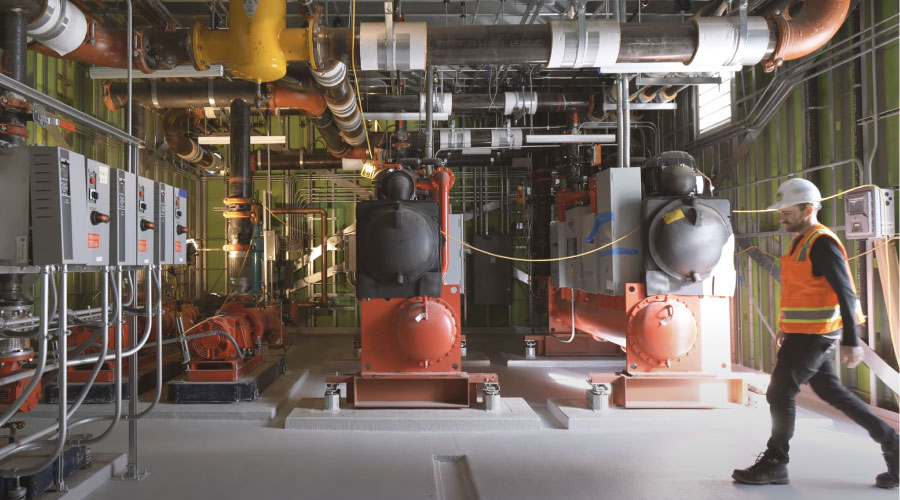

HVAC upgrades in facilities at Vanderbilt University gave managers the opportunity to incorporate new energy-saving measures and equipment, as well improve redundancy and service availability.

HVAC upgrades in facilities at Vanderbilt University gave managers the opportunity to incorporate new energy-saving measures and equipment, as well improve redundancy and service availability.How to Plan and Scope an HVAC Upgrade

Vanderbilt University’s experiences offer insights and ideas for delivering successful HVAC system upgrades

Once an HVAC upgrade receives funding, managers need to put together the schedule and gather detailed costs. Talk through the schedule with the contractor, including the way the work will be sequenced. For these types of projects, a large part of the time in the schedule is lead time for the new equipment to be built and shipped to the site.

Managers should talk to the contractor about preparation that can take place in advance of the new equipment arrival — for example, mobilization, pipe and duct installation, electric breaker and wiring installation. The schedule also has a substantial impact on the contractor’s costs related to general conditions, which are based on monthly mobilization, general, and administrative costs to be on the job site.

“Even for seemingly simple equipment replacements, it is crucial to include a representative of all parties for planning the installation of the equipment,” Hurt says. “At Vanderbilt, this may be facility maintenance, property managers, building owners, department heads, building security, finance, or Infection control directors (for hospital work). All these people are affected, and their input should be considered.”

Once the plan is developed, managing expectations is essential. Communicate the plan, including expected disruptions to the facility and contingency plans in the event of an unplanned power outage or loss of HVAC.

For example, during construction, will there be noise and dust for a month? What security protocols are required? Managers need to require the contractor to develop a contingency plan in the event of a loss of power, a loss of heating or cooling, or an errant fire alarm. Managers need answers to these questions in order to provide the answers to organizational leadership that will give them confidence in the manager’s ability to plan and execute a successful project.

The discussions also should cover logistics. Managers need to challenge the contractor to minimize downtime and clarify plans to remove the old equipment and install new equipment.

Testing, testing

Managers need to know the new HVAC equipment will work properly. Success means more than installing it, turning it on, and giving the thumbs up before they walk out the door. Managers need to make sure the contractor has commissioning support in their price.

Managers are responsible for defining commissioning. At a minimum, the contractor should have their TAB and controls contractor and equipment vendor on site while a third-party commissioning agent takes the equipment through various stages of operation to ensure functionality. This is functional performance testing. Include a line item in the bid form called commissioning support to make sure the contractor understands it is a critical part of that process.

In short, be clear about expectations and success by viewing the equipment replacement as an opportunity to further the mission of the building. Anticipate surprises, and when they occur, demand that partners have a contingency plan to avoid facility disruptions any more than necessary.

The overall challenge for managers is to work to truly improve the systems in the building instead of just replacing like for like. They need to demand that upgrade partners have the same viewpoint and approach. Let them know how important this project is to the mission of the facility or campus. Keeping all these things in mind will help managers navigate upgrade projects.

Casey Hester, P.E. — chester@ssr-inc .com — is mechanical department head for the Nashville office of Smith Seckman Reid — www.ssr-inc.com — a national consulting design engineering firm.

Related Topics: