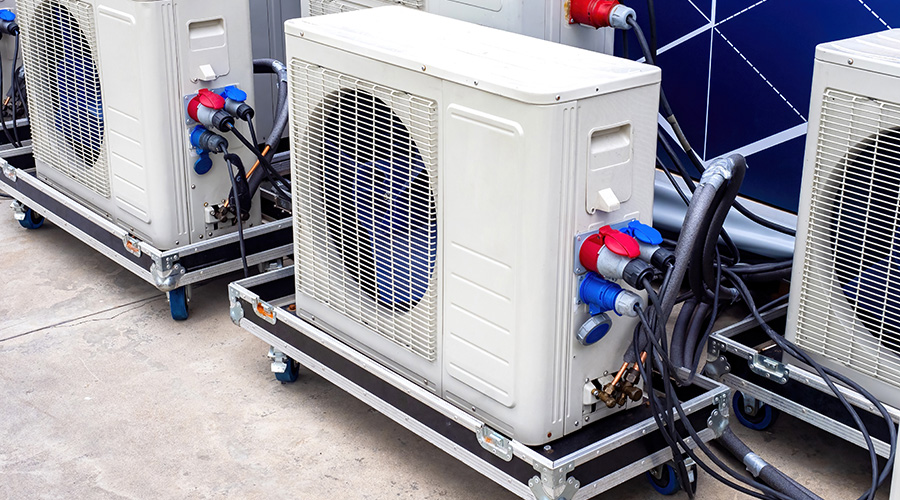

Energy efficiency goals for facilities at Collin College’s nine campuses led to projects that replaced aging chillers and boilers.Collin College

Energy efficiency goals for facilities at Collin College’s nine campuses led to projects that replaced aging chillers and boilers.Collin CollegeHigher Learning: Lessons in HVAC Efficiency

Collin College takes on HVAC projects to address enrollment growth, energy savings.

By Dan Hounsell, Editor-in-Chief

Things have changed at Collin College in recent years. Enrollment at the public community college system with nine campuses northwest of Dallas was growing, with 59,000 students working toward degrees and certificates in more than 100 disciplines.

Kenny Neal, the college’s director of facilities operations, knew the enrollment changes, coupled growing demands for heating and cooling, also meant changes for the college’s facilities and HVAC systems.

“I was tracking the annual electrical costs for (the college’s Frisco) campus, and I noticed an increase in the electricity usage,” Neal says. ”Also, some of the equipment was starting to age out.”

So in 2019, Neal and his team made the decision to invest in HVAC system upgrades at five campuses — as well as lighting, plumbing and fire safety upgrades — with a total value of $14.9 million.

Focus on facilities

Collin College consists of nine campuses north of Dallas, with a 10th campus set to be completed in mid-April 2021. The system’s three largest campuses are in: Plano, which has two facilities with a total of 662,000 square feet; Frisco, which has 10 buildings with about 562,000 square feet; and McKinney with four facilities containing about 500,000 square feet. The system’s oldest facility was built in 1985.

Each of the college’s campuses is assigned a facilities team.

“Depending on the square footage, that staff will include a facilities manager and two supervisors — one on the HVAC side and one on the maintenance side,” Neal says. “Each supervisor has support staff of HVAC techs and building maintenance techs.”

The campuses are spread out geographically, so each facilities group operates on its own.

“Each campus kind of functions as a standalone campus, and each campus facilities department has its own operational budget,” Neal says. “We don’t do deferred maintenance. We have what we call renewal replacement for equipment that reaches its life cycle, so we have a budget to replace that equipment as needed. I oversee all of the facility managers, so whatever they need, they come to me.”

Scoping the projects

Based on the college’s growing enrollment and the need for greater energy efficiency, Neal and his team took a closer look at the age and condition of existing HVAC equipment at several campuses.

”The two 250-ton units at Frisco were the original units from 1994,” he says. “Also, two of the three firetube boilers were the originals. So energy efficiency was the driver.”

Discussions regarding the scope and timing of the upgrade projects started in early 2018.

“After discussions on the budget and the payback, the projects were agreed upon,” Neal says. “The construction documents were released in December 2019 and the beginning of 2020.”

The Frisco campus received the bulk of the HVAC upgrades.

“On the HVAC side, it’s mainly the fan-powered boxes, the air handlers, replacing the motors, and new belts,” Neal says. “Some of them needed new sealants and insulation. At the Frisco campus, they replaced three firetube boilers with four condensing upright boilers, which are a lot more efficient.” The campus also upgraded four chillers — two 500-ton units and two 250-ton units — to four 500-ton Trane units.”

“In the process of deciding which manufacturer to go with, we already had a great relationship with Trane,” he says. ”Most of our campuses already used Trane, so the decision was made to go with Trane." The decision on which upgrade projects to undertake became a group decision.

“I had reviewed the list of potential projects and their payback and the issues that the other campuses decided with the various projects to be included with the college president, who also had input,” he says.

Meeting the challenges

As with most facility upgrade projects, Neal, his team and the installers ran into issues. Not surprisingly, high on the list of hurdles were keeping workers, students and staff safe while following COVID-19 precautions and at the same time avoiding disruptions to the core mission of the college — education.

“The major challenges were related to phasing the work and scheduling the replacement of the equipment in facilities that were in use,” he says. “COVID hit at the right time and wrong time. Sometimes, it was hard getting the shipments in, and it was hard sometimes scheduling the work hours around the class hours. We couldn’t do everything at night. Some stuff has to be done in the daytime. Replacing the boilers at Frisco was a challenge because we were still operating. We had to do it in phases. Then cold weather hit at kind of a bad time. It was challenging, but they worked through it.”

Prior to the COVID-19 shutdown, Neal and his team ran into scheduling issues. Needing to shut off equipment while facilities were occupied presented a tough challenge.

“When they were doing the air handlers, they might have needed three or four days to refresh that air handler,” Neal says. “Trying to relocate classes that were affected by the air handler shutdown proved to be difficult because some of the classes were specific classes that could only be utilized in those specific rooms. We could not just move those classes, especially if they were labs. And that type of work, we really couldn’t do it at night.”

Scheduling the work to accommodate the needs of students and staff involved a great deal of communication and cooperation.

“We worked around it, but it was challenging because there were a lot of moving parts involved when you’ve got the vice presidents of each campus involved in rescheduling classes,” Neal says. “And then you’ve got facilities and the contractor. To me, that was the major challenge — trying to minimize the inconvenience as much as possible.”

Delivering results

Despite the hurdles, the HVAC upgrades that have been completed have produced results as intended.

“The boiler they replaced at Frisco is performing better than expected,” Neal says. “We’ve had some pretty cold nights, and the guys have reported that only two of them are running. That campus is more than 500,000 square feet, so that’s good. We haven’t had any extended cold weather, but that’s pretty encouraging.

“We’ve only had the one chiller running because we haven’t had the load, so it’s kind of hard to gauge that. We’ll have a better sense of that once everything is completed and we have more of a load when the students come back.”

The HVAC upgrades will continue in 2021 as Collin College seeks to keep its equipment up to date and efficient as possible to meet the demands of a growing student population.

“For 2021, we have two sectional boilers at our Plano campus, and they are the original units that are 5 million Btus each,” Neal says. “They’ve been rebuilt, and they’re on schedule to be replaced hopefully in the summer of 2021. At the Frisco campus, we have a culinary arts campus that is about 10,000 square feet. In 2008, it was converted from a natatorium to culinary arts. At the time, they put the area on DX units. Now we’re looking to integrate that area into our chilled-water system. The DX units are not as energy efficient.”

Related Topics: