Classifying Motor Technologies

Specs have several ways of classifying motor technologies - by the type of electrical current used to operate them, by their energy use, or by function. Direct current (DC) motors are used for specific variable-speed applications and often are hand-built to those specs. Alternating current (AC) motors are built to standards established by the National Electrical Manufacturers Association (NEMA) and compose about 95 percent of the motors found in typical buildings.

Essentially, AC motors found in buildings are either pump motors or fan motors, says Richard Halfpap, marketing manager for Marathon Electric Manufacturing Corp., a division of Regal-Beloit Corp.

"Pump motors are very often the lightest duty from a mechanical standpoint, particularly in horizontal applications," Halfpap says. "The majority are medium-sized, centrifugal systems sized for commercial buildings and industrial buildings that heat with water. Typically, they are 1/2 horsepower to 1 horsepower and operate in clean environments."

Larger pump motors can be found in utilities and wastewater treatment applications. These motors are relatively large, and many applications are vertical, having thrust bearings that might need additional maintenance.

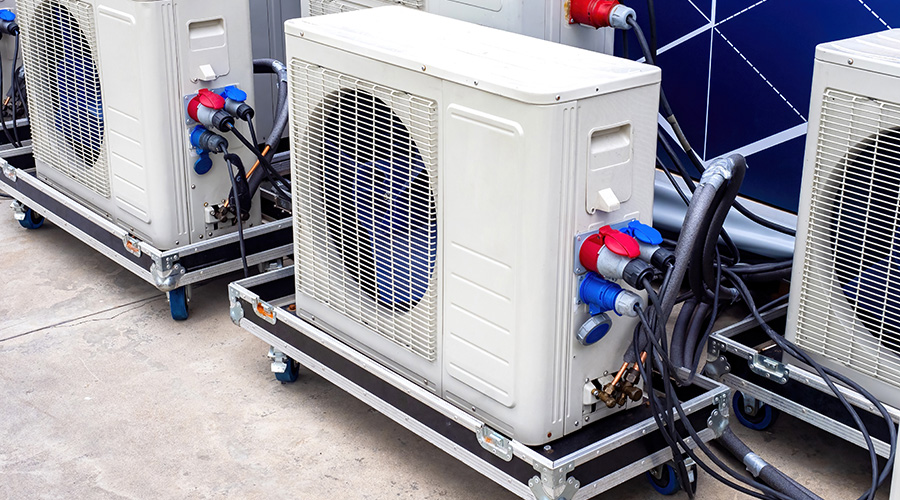

"Fan motors can be belted or direct-drive units," Halfpap says. "Both types are commonly used in commercial and industrial buildings. They range in size from very small (fractional horsepower) to large (10 horsepower or more), with larger motors being used for rooftop ventilation units and to supply drafts for large boilers."

Fan motors and pump motors represent 65-70 percent of all motors in the United States.

A third way to classify motors is by their energy efficiency. There are standard motors; motors that meet the Energy Policy Act, which went into effect in 1997; and the highly efficient NEMA Premium™ motors.

Related Topics: