Boilers and Water Heaters: Identify Water Use

Rising costs and increasing use restrictions are forcing many engineering and maintenance managers to implement comprehensive water-conservation programs. Most already have implemented programs to minimize water use in restrooms through the use of low-flow fixtures or have installed automatic controls on irrigation systems. While these programs generally have succeeded in reducing water use, many ignore a third major target area for curtailing water use — mechanical systems.

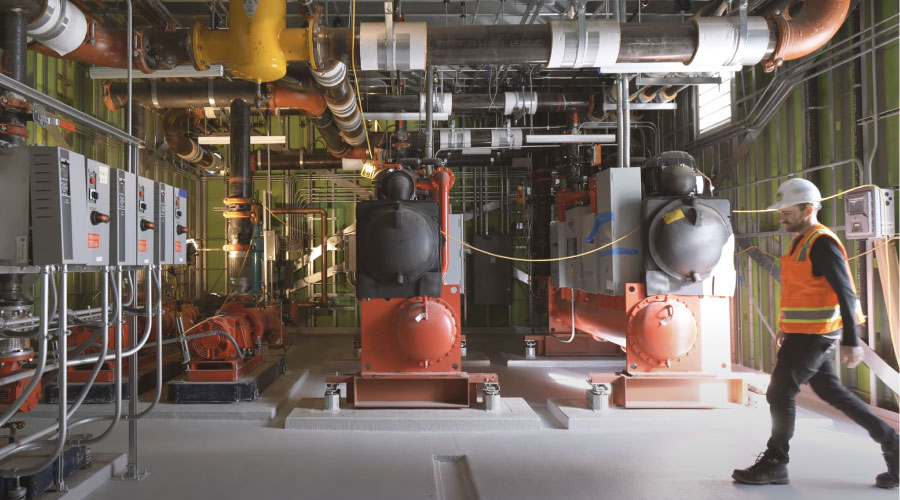

Mechanical systems require significant amounts of water during normal operations. In a typical facility, the water use by HVAC systems accounts for more than one-third of the facility's total consumption, and that amount can be larger if the systems are not operating properly. Problems such as leaking or failed valves and improperly set systems can increase their demand for water significantly.

Fortunately, managers can take a number of steps to curtail water use by mechanical systems — in particular, boilers and water heaters — without disrupting operations.

Tracking Water Use

The first step in controlling the amount of water mechanical systems use is to identify each system's water use. Most mechanical systems operate behind the scenes, so managers can lose track of their demands for water. Technicians also can easily fail to detect system leaks and other malfunctions, often for months at a time.

Tracking water use starts by identifying the major water-using mechanical systems, including boilers, domestic water heaters, cooling towers, and once-through HVAC systems. Technicians can install a separate meter on each system to identify the demand for water. They must make certain the controls that regulate the system's water use operate properly and monitor water use over a specific period.

For some systems, such as larger boilers and cooling towers, it might be necessary to record water use daily. For other systems, it might be best to record water use weekly or monthly. These readings will help managers identify systems with high requirements for water and set a baseline for use.

Managers must be careful when establishing a baseline for water use. If technicians do not detect and correct leaks and other malfunctions within the system before readings begin, the result will be a baseline that is higher than it should be.

It is not enough to just record water use. Once managers have established the baseline, technicians need to monitor readings regularly and compare them to the baseline. If readings deviate, technicians will need to investigate and identify the cause of the deviation.

Related Topics: