Advanced Digital Technology Revolutionizes Boiler Market

The building internet of things and artificial intelligence are bringing powerful new capabilities to boiler controls.

Controlling heating and domestic hot water boilers is not an easy “one size fits all” proposition. Boiler manufacturers need to keep using old and proven technology developed from centuries of code development and safety protocol. Control developers, meanwhile, are increasingly adopting newer technologies, and driving significant changes in how we integrate these appliances into building operations.

Boiler controls have gone from simple operating thermostats to sophisticated building internet of things (B-IoT) compatible devices in less than three decades. Boiler companies need to take a layered approach toward ensuring safe and efficient operation, while being open to the newest opportunities for integration with building automation systems through B-IoT and augmented intelligence software.

Once the basic boiler housekeeping and safety monitoring control functions are taken care of (See “With boiler controls, it’s safety first” on page 16), designers move out to the first layer of control and things start to get quite interesting — the choices are many.

Integrated boiler controls

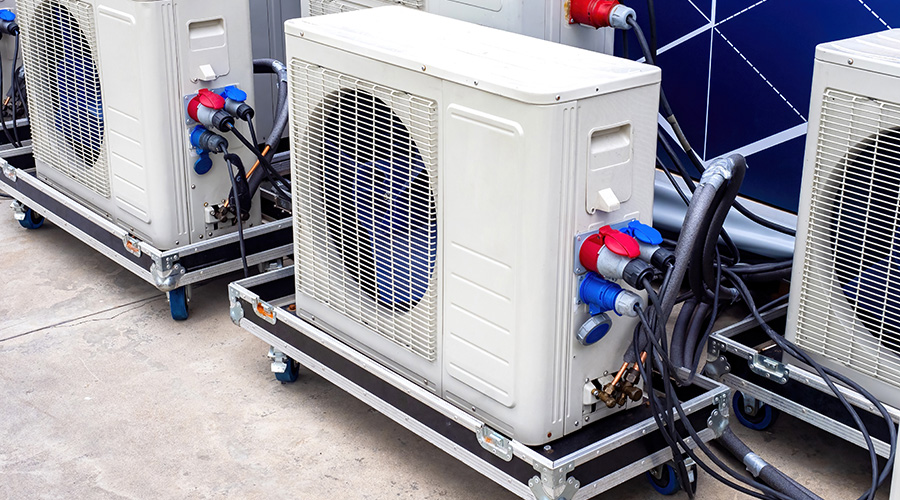

In the medium to large commercial boiler world, full integration with the BAS has become mandatory for many building owners, and the industry has stepped up to the task, and then some.

Integrated boiler controls have been available for many years now, with manufacturers providing their top boiler models with the option to integrate with the BAS, primarily through BACnet or LonWorks. These are considered mature technologies, which became popular in the mid 1990s and developed hand-in-hand with robust standards to ensure safety and reliability.

Any device in a building HVAC system can have the ability to connect to the BAS provided it is supplied with the necessary hardware and software to communicate through its specific open network. A BAS system is essentially a supervisory control and data acquisition system designed to communicate with the networked equipment and compile the information in useful ways. Building operators and engineers still need to compile or develop the required software to meet the specific requirements of each building — no small task. The remote controllability options of any given boiler, and the amount of data that can be read, will vary from manufacturer to manufacturer depending on the power of the processor provided and the sophistication of its software. Building owners and staff should discuss their networking requirements in detail with individual boiler manufacturers, to ensure that the control equipment being offered will indeed be able to do what is expected of it. In many cases BAS operators will still need to add sensors relays and other devices to a boiler system to get all of the information they want.

The outer layer of boiler control capability when connected to a network includes the following:

Basic, subordinate — These are simple controls that look after basic boiler safety functions but require precise commands from the BAS system. Typically these controls are enabled by one signal to make the boiler “go,” and another signal to tell it to deliver a specific water temperature (determined by the BAS software written for the system). Boiler function information (boiler on, flame on, temperature, alarm, etc.) can be read by the BAS system.

Smart, subordinate — These controls are programmed on-site, with functions like outdoor reset and domestic hot water priority, staging, pump operation, etc. These functions can be monitored, and some override may be possible within the programmed parameters. Data logging, diagnostics, and operating functions can be read by the BAS system.

Smart, integrated — These controls can operate as stand-alone devices or be dumbed-down to be subordinate to the system. All functions, except those that are critical and safety-related, can be overridden or re-programmed remotely by BAS operators or by augmented intelligence software. Most of these controls can default back to internal programming if external control signals are lost or if the BAS system is programmed to pass control back to the on-board devices under certain circumstances.

Related Topics: