Chillers: Repair or Replace?

Gathering and analyzing data builds the foundation needed to make a cost-effective decision

Chillers are an enormous cost for facilities, both for first costs and operation expenses. They use tremendous amounts of energy and require regular maintenance. For maintenance and engineering managers who are not intimately aware of their organization’s chiller performance, maintenance and cost data, chillers can appear outlandishly expensive. But in-depth knowledge about an facility’s chiller maintenance and operation can help control chiller expenses and make decisions on chiller replacement easier.

Changes in refrigerant supplies also are causing managers to rethink chiller replacement time lines. However, most managers should decide when to replace a chiller by assessing maintenance and cost data and by reviewing the benefits gained by upgrading to chillers that use the latest generation of refrigerants.

Tom Heck, director of plant operations at King’s Daughters Medical Center in Ashland, Ky., recently faced just such a decision. The center’s growth required plant expansion, so, armed with the data gleaned from maintenance logs and operation expenses, and mindful of refrigerant phaseout considerations, Heck was equipped to specify a chiller that best suited his organization’s expansion.

Performance and Operation Logs

The basis for many decisions regarding chiller maintenance and replacement decisions is chiller performance data. Heck says his staff regularly records the loads and amperages of his operation’s chilled-water system.

Al Asendorf, a heating and ventilation supervisor at State University of New York-New Paltz, also tracks water temperatures. He says his organization keeps the logs to track efficiency loss.

Every maintenance and engineering department should undertake such practices, says James Piper, a consultant with more than 25 years of experience in maintenance, engineering and facility management. Technicians also should check and record power consumption, chilled-water supply and return temperatures, chiller current, water flow, and condenser-water supply and return temperatures. With this data, managers can gain a rudimentary but accurate sense of chiller efficiency.

To create a more accurate picture of operating efficiencies, technicians should record energy-use measurements for all equipment in the chilled-water system, including chillers, pumps and cooling towers. Although technicians can estimate operating efficiencies by conducting false-load tests, Piper recommends a longer and more complex audit process. An audit conducted over several weeks or even months gives managers a more accurate picture of operating efficiencies. Piper recommends managers review the chiller’s operating log and ask the following questions:

- Are maintenance entries made regularly?

- Does recorded data fall within the chiller’s normal operating range, or does it show that something is forcing the chiller to operate at less than optimal efficiency?

- What is the setting for the chilled water supply?

Inspection Strategies

Regular inspections also keep the chillers at Kaiser Permanente’s Vallejo (Calif.) Medical Center operating with better information, says Ron Bass, the center’s facilities services manager.

“We conduct quarterly inspections, which are very basic,” he says. “Then we also do an annual maintenance inspection on each of our chillers, which is more in-depth. We essentially do a complete system check; we do an oil analysis and perform a flow check, for example.”

In New York, where chiller use is seasonal, Asendorf says SUNY-New Paltz will perform extensive oil, refrigerant and other checks twice a year — once in spring or summer, and again upon shutting the chilled water system down in the fall.

Managers also should schedule time for technicians to clean scale from heat-exchanger tubes every two years to optimize operating efficiency, Piper says. Tube cleaning should take place before an audit to ensure the accuracy of efficiency measurements. He also says inspectors should look for other causes of low operating efficiencies, including high purge-unit run times, which might indicate an efficiency-robbing air leak.

Other weekly inspection duties should include a check for unusual noises or vibrations, and annual checks should include refrigerant testing, controls calibration, safety tests, and inspections of wires, cables and disconnects.

Maintenance Data

Technicians should record the results of regular inspections and all maintenance tasks. Bass says his organization keeps daily round sheets on preventive maintenance duties. Technicians record any chiller maintenance, whether performed by in-house technicians or outside contractors.

Managers should not underestimate the value of recording even seemingly minor maintenance, such as the addition of oil or making minor adjustments. Technicians who include such detailed maintenance information in their reports give managers the information on which to base their chiller maintenance and upgrade decisions.

While such detailed maintenance data might not reveal short-term problems, extensive maintenance logs can help managers identify long-term trends that can compromise chiller efficiency and affect the organization’s bottom line.

Cost Considerations

Chiller expenses are numerous and can add up quickly, so managers should track power costs, maintenance costs, and a number of other related costs.

At the King’s Daughters Medical Complex, Heck says the organization’s accounting system tracks maintenance expenses, and the hospital’s chemical cost center helps Heck keep a close eye on refrigerant costs.

“We’re always looking forward,” he says, and adding that his organization selects the newest generation of refrigerants because of their cost-effectiveness.

Managers also can use cost data related to chiller operation to plan for future refrigerant phase-out costs and to gain credit for refrigerant leakage savings.

Bass says that while Kaiser Permanente doesn’t track costs down to the daily maintenance expenses, his hospital’s cost data might help him build a business case for replacing 10-year-old chillers that exhibit chronic operating problems. For more on building a case for replacement, see the accompanying article on this page.

Evaluating Data

Once managers have gathered and analyzed data on chiller performance, maintenance and costs, they can use such information to make a case for the repair or replacement, including a cost comparison of existing equipment and new equipment. Typically, these costs might include:

- total equipment expenses, including installation

- maintenance costs

- energy consumption costs

- refrigerant costs, including phaseout costs.

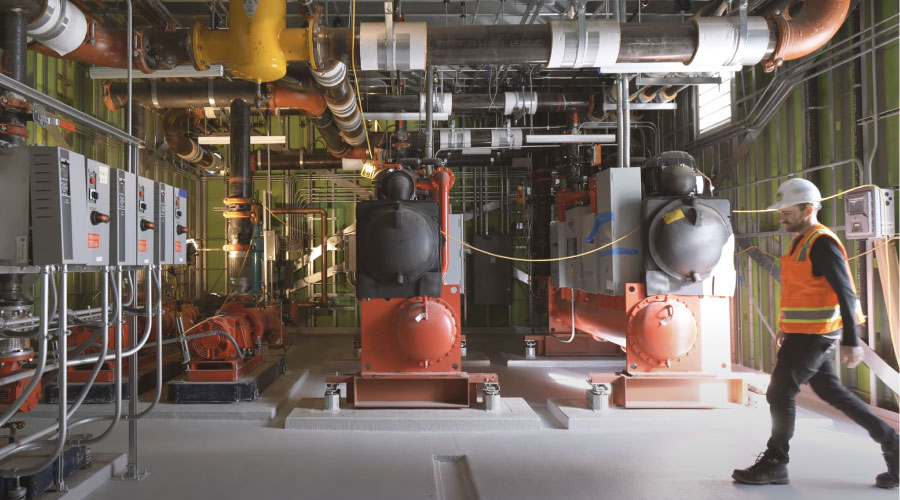

Maintenance managers also might consider costs for upgrades to mechanical rooms or plants to accommodate the new equipment, if necessary.

If chiller replacement seems like the best option, managers then can begin the process of cost-justifying the investment to the building owners and executives. Operating logs can help managers determine their facility’s cooling demand, including run times and loads, and maintenance data helps quantify the kinds of routine maintenance that are required during a chiller’s life expectancy. Managers then can marry this information to cost data and chiller manufacturer specifications to help find support the maintain-or-replace decision.

Such information makes it possible for managers to anticipate life-cycle costs and build a solid, clear case for taking action to improve chiller efficiency and the organization’s bottom line.

Case study: When chillers fail

Ron Bass seems to have mixed emotions about high-efficiency chillers, given his recent experiences. In fact, poor performance from some of the newest chillers at the Kaiser Permanente Vallejo (Calif.) Medical Center has led Bass to investigate replacing the chillers after only 10 years of operation.

Bass cautions, however, that most of his chiller maintenance experience comes from working with one manufacturer’s equipment.

"It seems that our R-11 units are fairly bombproof," he says. "But despite efficiency increases, some of the new machines have their own problems in terms of reliability."

Impeller seals and oil pumps have failed on multiple machines, Bass says, adding that he has had five catastrophic chiller failures in two facilities during the last six years. Bass characterizes a catastrophic failure as an inability to produce chilled water and a breakdown that incurs more than $5,000 in damage.

“We had one failure that cost our organization $60,000, and this was on a machine that isn’t even 10 years old," he says. His first serious chiller breakdown occurred before the machine was even two years old.

Bass says the manufacturer has been unresponsive, given the nature of his organization’s chiller failures. He says the equipment’s downtime, maintenance costs and the manufacturer’s attitude have combined to lead him to investigate chiller replacement, even though the failing machines haven’t yet reached the midpoint of their expected performance life.

"Our organization is such that I could build a business case for chiller replacement, even though these machines are still quite young," Bass says. "Our annual preventive maintenance on failing equipment is far more than for some of the older, more durable machines."

Bass says he could use his organization’s data to calculate run times, maintenance costs and, if the payback was less than five years, he would stand a good chance of gaining top-level support for chiller replacement.

|

Related Topics: