Managers who closely monitor and analyze the operation of HVAC systems can achieve savings.

Managers who closely monitor and analyze the operation of HVAC systems can achieve savings.Energy Waste: Improving HVAC Performance

Managers who seek feedback from building occupants can better understand how well the HVAC system is performing.

One of the most important steps in improving HVAC performance is the one managers most often skip: communication. HVAC systems are designed to provide comfort and support operations, but rarely do systems managers actively seek feedback from building occupants as to how well the system is serving their needs. What little feedback they do get usually comes in the form of complaints.

While this feedback is important in day-to-day operations, it does not tell managers much about the overall performance of the HVAC system, nor does it tell them what occupants need or expect. That information can be developed only by communicating with occupants.

First, managers need to walk the building and talk to occupants. What do they need for their operations? Do some operations require special HVAC services? Do they operate equipment that has demanding requirements for temperature and humidity control? What are their hours of operation? Remember, the primary purpose of any HVAC system is to provide comfort to occupants and to support their operations. If managers do not know their requirements, it will be impossible to provide the necessary support.

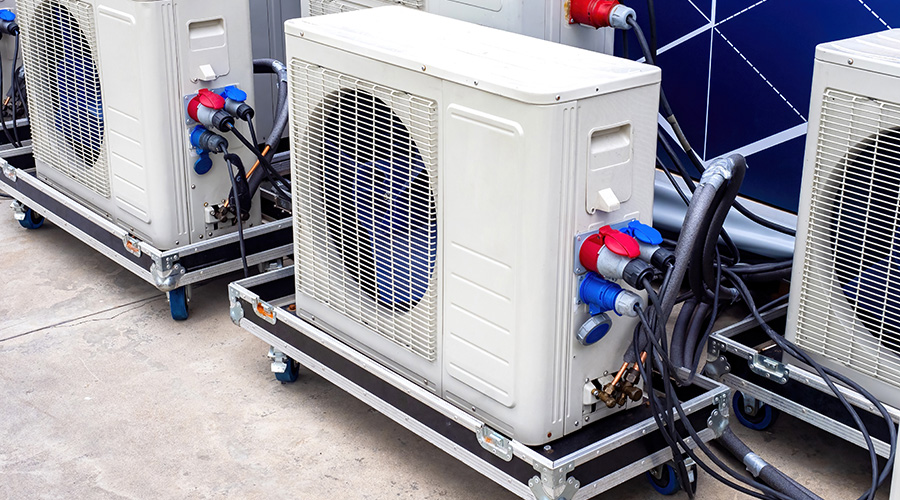

The next step in the evaluation process is to perform a visual inspection of the entire system, from the outdoor air intake grill to the room diffusers. At this point, it is not necessary to take measurements. That will come later. The purpose of the visual inspection is to identify conditions that would negatively affect the operation of the system.

Start with the outdoor air portion of the HVAC system. Is the outdoor air intake grill located near a source of contamination, such as a loading dock or a dumpster pad? Is the grill free of debris or is it clogged? Has the damper control been disconnected? Is there damage to the ductwork that would interfere with how much outdoor air is being drawn into the system?

Inspect the air handler. Is there corrosion on the unit’s casing or condensate pan? Is water dripping from the unit? Are the filters structurally sound? Have control linkages been disconnected or wired in a set position? It is not uncommon to find that changes have been made to system controls in order to achieve a temporary solution to a problem, only to have that solution become permanent, even though it might be harming performance.

James Piper, P.E., is a national consultant based in Bowie, Md. He has more than 30 years of experience with facilities maintenance, engineering and management issues.

Related Topics: