VRF technology continues to grow in popularity and could be the solution for managers seeking to address air conditioning comfort and cost concerns in their facility.

VRF technology continues to grow in popularity and could be the solution for managers seeking to address air conditioning comfort and cost concerns in their facility.VRF: Focusing on Fine-Tuning

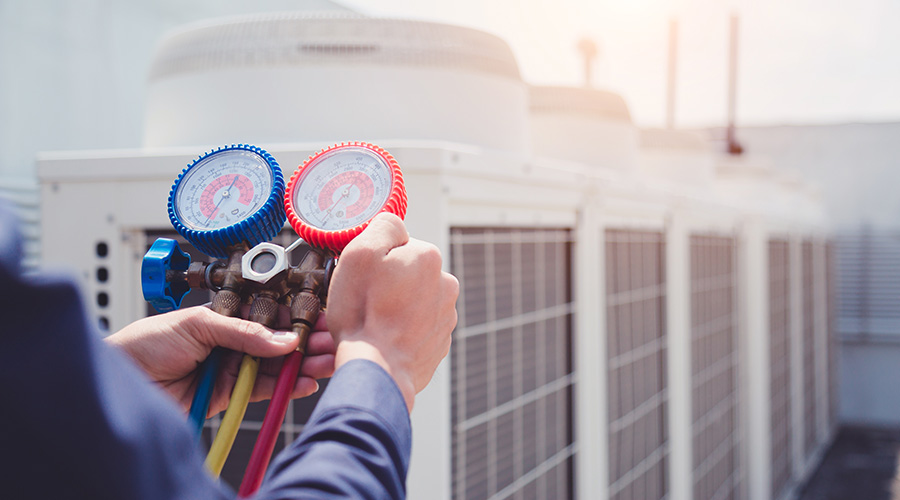

VRF systems are sensitive to accurate charging levels. Technicians need to perform field charging according to manufacturer instructions and established practices.

VRF systems are sensitive to accurate charge levels. Technicians must avoid overcharging and undercharging, and managers must observe manufacturer-published values for weights of operating refrigerant in the additional field-installed piping. Technicians need to perform field charging according to manufacturer instructions and established practices.

Failing to observe precautions can result in poor performance, erratic operation, and premature failures in compressors and control components. When compressor burnouts contaminate piping systems, they become difficult and expensive to clean, and fugitive residues will cause additional failures until technicians remove them.

Contamination with water and debris was a bad issue with traditional halocarbon-based systems, and it presents even greater challenges when using R410a. Mineral oil lubricants commonly used in halocarbon refrigerant systems had to be replaced with polyolester oils, which are excellent solvents and comparatively hygroscopic. Technicians must prevent the presence of water in any form because even a small amount will cause control valve operation problems and lead to the internal formation of corrosive acids.

These challenges place a premium on correctly handling refrigerant components and lubricants, and on requirements for higher-quality moisture-removal capabilities. Technicians must conscientiously maintain dry systems during and after installation. Systems typically require better grades of particle filtration and moisture removal.

Systems with multiple fan-coil terminals assigned to one condensing unit present an added complication — ensuring piping systems and controls are connected to the correct terminals. Serious errors in connection and control assignments, such as connecting two terminal units to the wrong line-sets, can be disastrous for the equipment. The best antidote is expert design, installation and commissioning.

Commissioning VRF systems requires more experience and skill from the provider of commissioning services. The provider should have direct experience in designing, installing and operating split-system air conditioning and understand issues and trade-offs.

VRF equipment service life expectancies are similar to those for traditional split-system equipment, and they are normally lower than those for large central-station apparatus. Due to the increased number of maintenance and inspection points, the overall level of effort to maintain VRF system components is higher, but when conscientiously performed, they can yield entirely satisfactory performance lives.

Jack de Pagter, P.E., is a senior project engineer with Horizon Engineering Associates — www.horizon-engineering.com. He has more than 40 years of experience providing engineering services and specializes in the commissioning, qualification and validation of commercial buildings.

Related Topics: