How Chiller Plant Optimization Improves Building Performance

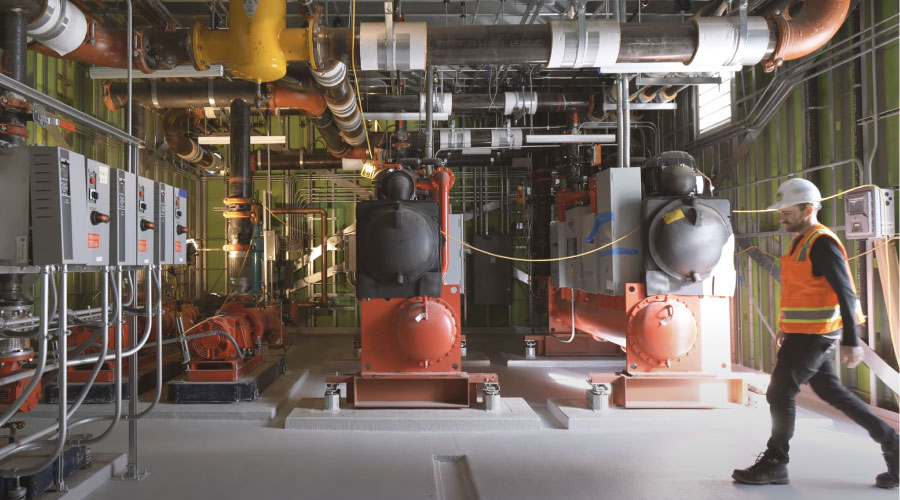

Because the chiller plant is often considered the “heart” of a building’s HVAC system, particularly for larger facilities, chiller plant optimization is critical to achieving better building performance. Not only is the chiller plant the main source of cooling, but its power requirements make up a large amount of a building’s energy needs. Consider that in a typical Las Vegas casino property, for example, the HVAC system can equal 60 percent of the total electrical load, and the plant represents a major portion of that HVAC load.

A primary challenge with chiller plants is that many do not operate at their designed temperature differential. The designed temperature differential is the difference between the chilled water supply temperature and the chilled water return temperature, referred to as “delta T.” It is not uncommon to find plants operating at less than optimal levels, at a far lower delta T than necessary based on the original design. This can be due to a number of factors, including how the chiller plant equipment is controlled or even how the airside systems (air handlers, fan coils, etc.) are operating.

The key to efficient plant control starts with the operation of the chillers and chilled water pumps. The variable-primary chilled water system is a more efficient chiller plant arrangement because only one set of pumps is used to move water through the chillers and throughout the building systems. The other arrangement is primary-secondary, which includes two sets of pumps — one for the chillers and the other for the building systems. All chillers have a designated temperature differential. As an example, that differential might be 12 degrees F. Every chiller also has specific data containing critical information about its operating characteristics, which includes its design delta T.

Proper control of the plant equipment, including the chillers, pumps, and cooling towers, is of utmost importance, particularly in combination with a quality control system. A control system that operates properly enables coordination of all system aspects and facilitates access to the chiller’s actual internal data. This allows the use of that data as input to create an efficient chiller control program. It is essential to have a highly proficient understanding of chiller operation in order to most effectively control the plant. Monitoring the chiller’s refrigerant pressure through the building management system makes it possible to determine the sweet spot of the refrigerant lift. This controls the chiller at its most efficient operation, regardless of load percent. If sufficient expertise is not available in-house, facility managers should consider employing a reliable controls partner for optimization.

Related Topics: