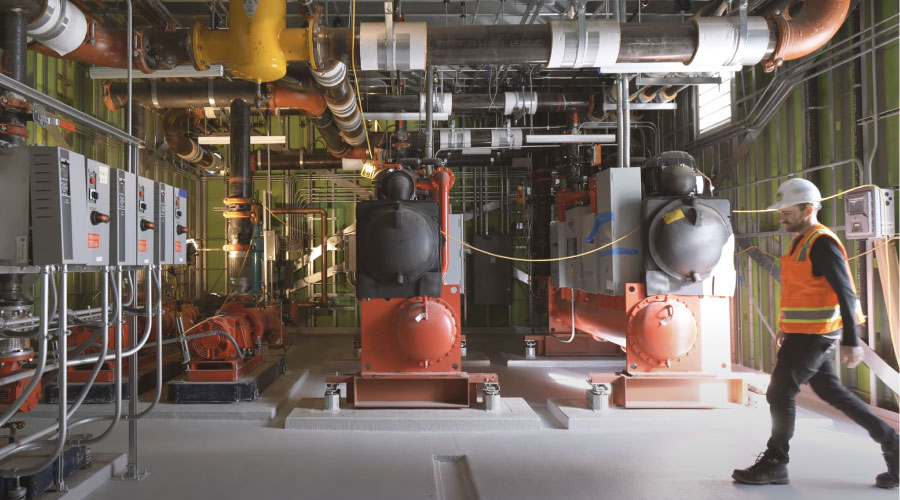

HVAC Opportunity: Improve The Efficiency Of The Heating And Cooling Distribution Systems

Another HVAC opportunity: improve the efficiency of the heating and cooling distribution system. This improvement should address both peak-load and part-load efficiency, since most HVAC systems operate mostly at part load. Good part-load efficiency for distribution systems often involves variable speed drives along with components to allow drives to operate at lower frequencies as often as possible. For fans and pumps, facilitating variable flow operation is a must.

One way to reduce transport energy is to use water, as much as possible, as the heat transport fluid. Transport of heat by water is 4 to 10 times as energy efficient as transport by air. The trade-off is that free-cooling strategies are less effective in water-based distribution systems. Water systems are most effective in climates that are too hot and humid for airside free cooling, or so cold that waterside free cooling is frequently effective. For these climates, a dedicated outdoor air system with heat recovery, for ventilation and dehumidification, along with a primarily hydronic sensible heating and cooling distribution system, such as fan coils, chilled beams, or radiant panels, is likely the most energy efficient selection.

At peak load, efficiency can be significantly improved by minimizing pressure drop. For hydronic systems, pipe sizing and selection of valves are critical. Similarly, for air distribution systems, duct sizing, selection of aerodynamic flow accessories — such as turning vanes — and optimal sizing and selection of dampers are critical. Coils and other heat exchangers should be selected for reduced pressure drop on both the primary and secondary sides of the exchanger. Minimized approach temperature should also be considered in selection of coils and heat exchangers. The ideal distribution system, whether air or water, features reduced pressure drop along with maximized temperature differential across the system.

For variable flow systems to be effective, capacity reduction should be accompanied by flow reduction. Two-way control valves should almost always be specified for hydronic distribution systems. Some systems require a minimum flow rate, so the use of a controlled minimum flow bypass may be required. The bypass is preferred to using a limited number of three-way valves, because the three-way valves will increase flow through the system when actual required flow is above the minimum, increasing pumping energy.

Appropriate selection of prime movers is also important. Pump and fan curves can be compared to find the best selection for each application. In general, larger diameter, slow rotation speed selections are more efficient, up to a point, although the designer should avoid selections for which a slight miscalculation of the system pressure drop might result in an undesirable operating point.

Related Topics: