Boiler Controls Incorporate Microprocessors, Solid-State Sensors

The U.S. Department of Energy estimates nearly 80 percent of operating boilers in institutional and commercial buildings are more than 30 years old. Of these, fewer than one-half have undergone any major upgrades since their installation. Combine the age and the condition of the boilers with advances in boiler-control technology over the past 30 years, and chances are good managers of these facilities are working with boilers that are not operating even close to optimal efficiency.

While replacing these older boilers with new units will result in major gains in energy efficiency, total replacement might not be the most cost-effective option. As long as the overall condition of the boiler is good, managers might want to consider upgrading only the boiler's controls instead. New boiler controls can provide major gains in energy efficiency, performance, and safety at a much lower cost.

A New Generation

Older-generation boiler controls used mechanical linkages. With age and use, linkages wear and go out of adjustment, reducing the unit's efficiency. Older-generation controls also suffer from offset, which occurs when the system operates close to, but not exactly at, the desired setting.

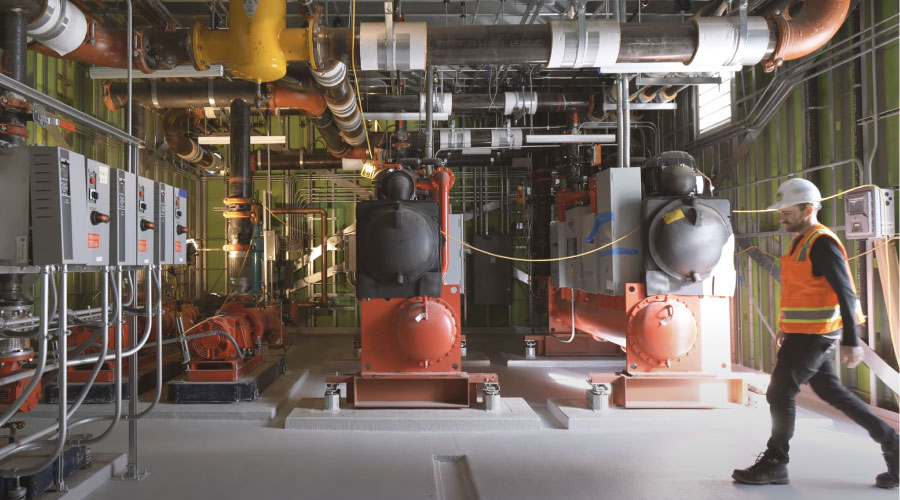

Today's boiler controls incorporate microprocessors, solid-state sensors, and independent servo motors, which give managers accurate and reliable operation, eliminating problems such as offset.

When evaluating control options, it is important to remember boiler controls perform three basic functions: combustion control; water-level control; and flame safeguarding. If a facility uses multiple boilers, the control system must perform a fourth function: sequencing. Managers must factor all of these issues into their control decisions.

Related Topics: