How Lean Design, Construction Techniques Trim Healthcare Costs

Part 1 of a 3-part article on how healthcare facilities are improving efficiency in design, construction, and operations

Lean design and construction is a production-based methodology for project delivery that focuses on increasing efficiency and reducing waste. Companies need to operate as efficiently as possible, and lean techniques can help healthcare facilities save money and be more efficient. Among the available tools are spaghetti charts to spot design problems, a methodology called choosing by advantage, which aids design decisions, and virtual mock-ups.

Lean design includes workshops and activities with end users, such as potential tenants and facilities staff, which help the architect design the most efficient layout of a facility. Lean design in healthcare facilities is laser-focused on improving efficiency and the patient experience, including:

- Reducing the number of nursing staff needed per patient bed.

- Reducing the amount of time a patient spends in the hospital.

- Reducing patient service time.

- Reducing the use of excess materials, supplies, linens, etc., and the associated inefficiencies of managing these items.

Lean design activities and workshops in healthcare projects include spaghetti charts to track the number of steps taken by nurses or other providers in their daily course of work. A spaghetti chart tracks all of the steps taken to complete a task or work day and shows all of the lines of their walking pattern on paper. The spaghetti chart often identifies areas where workers walk excess distances or multiple times to do one task.

These findings are taken into account in designing the new facility, the goal being to reduce the number of steps and the distance traveled to accomplish the task. At the Providence Regional Medical Center in Everett, Wash., for example, the design intentionally minimized the distance required for nurses to travel from nurse stations to patients and supply rooms. As a result, the hospital is operating in the 90-plus percentile for nurse staffing per bed.

Another tool used is choosing by advantage, a methodology that helps stakeholders analyze and select the best options for the facility. For example, several mechanical systems could be evaluated based on the different advantages they offer, and by systematically evaluating these different options, owners can decide which option provides the greatest advantage to their situation.

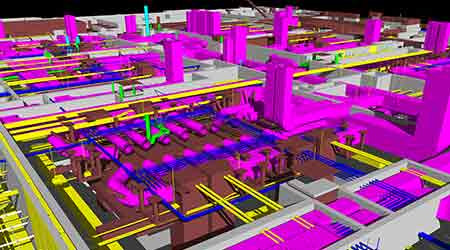

Additionally, virtual mock-ups using 3D Building Information Models (BIM) facilitate streamlined owner decision making and support an iterative redesign process virtually rather than making physical and costly changes to in-place work product in the field.

Flexibility is highly important in designing today’s healthcare facilities. Modular casework, demountable walls, and raised floor systems for easy access maximize flexibility and convenience. These design solutions address the continuous evolution of technology and patient care experienced by healthcare facilities as they identify more efficient ways of operating. For example, modular casework was included in the design of the Swedish Ballard Medical Office Building in Seattle to allow for convenient change of organization and flow in doctor and nurse work areas.

Related Topics: