The designs for Terminal 2 and 3 at SFO incorporate biophilic design by using subtle shifts in pattern, lighting, and even ceiling height that provide a variety of experiences for the travelers who walk along the concourse to and from their gates. Nic Lehoux

The designs for Terminal 2 and 3 at SFO incorporate biophilic design by using subtle shifts in pattern, lighting, and even ceiling height that provide a variety of experiences for the travelers who walk along the concourse to and from their gates. Nic LehouxSustainable Goals: Biophilic Design, Reduction of Carbon Footprint

At SFO, reconnecting travels with nature while reducing the carbon footprint by carefully selecting materials have been major ongoing goals.

There has been a shift from thinking purely about the environmental impact of the building industry to a desire to understand how the built environment affects occupants’ health and well-being. Biophilia is the human urge to affiliate with other forms of life. Connecting love of nature and life to the design of spaces can reduce stress, enhance creativity, help a person heal faster, or simply provide a moment of joy.

(Departure waiting areas at SFO provide seating and environment options that allow a person to be in the open and engage with their surroundings. Photo credit: Joe Fletcher)

An airport terminal is usually the opposite of “natural.” Out of necessity, it is mechanically ventilated and sealed off from the outside world, filled with hard surfaces, and surrounded by acres of concrete. The spaces are often acoustically and visually chaotic, contributing to a higher level of stress than most indoor environments. The design firm Terrapin published 14 Patterns of Biophilic Design, which is a useful tool for exploring design opportunities beyond potted plants and large-scale graphic images of nature. It includes strategies like “dynamic and diffuse light” and “visual connections with nature,” as two examples. The designs for SFO’s Terminal 2 and Terminal 3 incorporate subtle shifts in pattern, lighting, and even changes in ceiling height that provide a variety of experiences for the travelers who walk along the concourse to and from their gates, without calling too much attention to these changes. Departure waiting areas provide seating and environment options that allow a person to be in the open and engage with their surroundings, or to be slightly cocooned in a tall comfortable lounge chair, while keeping an eye on the activity around them. Groups of seating under a lower ceiling with views towards the airfield or the higher spaces of the concourse support the theories of Prospect and Refuge — giving a sense of safety and control over the environment.

The importance of seeing natural elements and living things has informed the latest design strategies for Terminal 1 at SFO, currently under construction. When the terminal is completed in 2021, passengers will have views of large landscape elements on both sides of the security checkpoint, visually connecting with sky and taller plantings immediately beyond large-scale windows at the curbside. A Recompose area just beyond the checkpoint will have a sculptural stair, plantings, and a water feature that will signify a different type of experience at security.

(At SFO, some seating is designed so that travelers are slightly cocooned in tall comfortable lounge chairs, while they're still able to keep an eye on the activity around them. Photo credit: Nic Lehoux)

Carpet footprints: The carbon kind

In the ongoing drive to design, build, and operate buildings in a more environmentally responsible manner, new performance standards and measurement protocols are emerging to help assess the impact of product selections on a more scientifically rigorous basis. Whereas before, facility managers would often rely on attribute proxies such as bio-based or recycled content, the new standards make it possible to calculate and present comparative analyses using globally recognized criteria such as global warming potential (also referred to as carbon footprint). Additionally, facility managers can now conduct assessments at a product level (like carpet), at the tenant fit-out level, at the whole building level, and from a project’s full life cycle perspective.

The basis for these standards derives from work performed over the decades through the evolution of the ISO 9001 quality standards and the ISO 14001 environmental management standards. Within the 14000 series, we have the ISO 14025 and 14040-44 standards tackling lifecycle assessment and reporting. These include very specific protocols for developing Product Category Rules (PCRs) as well as Environmental Product Declarations (EPDs) which at the end of the day enable all facility managers, as building performance guardians, to truly understand and account for the impact of the products selected for installation.

While it’s still the early stages of using life-cycle based performance as a tool in selecting products, a number of manufacturers within key product categories have been stepping forward to encourage the development of relevant PCRs as well as to complete and release their product specific EPDs. Designers and facility managers now have available a rich body of environmental data, including carbon footprint insights, for concrete, steel, and wood structural elements, ceiling tiles, wallboard, carpet, resilient flooring, roofing materials, hardware, and seating.

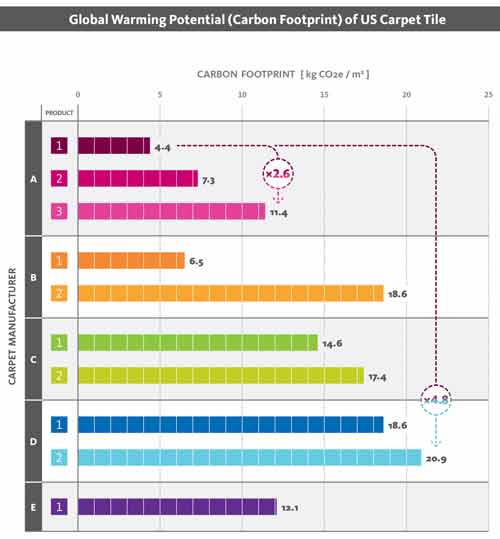

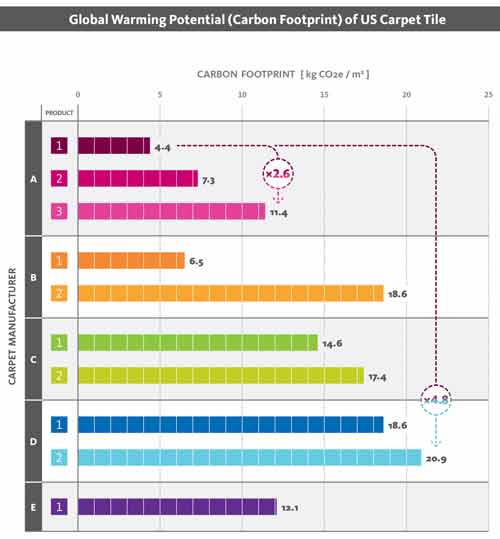

At SFO, particularly for Terminal 1, sorting through the available life cycle/EPD information to understand the true relative impact of different products and even different manufacturers in a single product category has been a particular point of emphasis, and eye-opening for all those involved. For example, even for a product category like carpet tile, which many facility managers might think has a relatively similar environmental impact, within a single manufacturer’s product offering, there can be a 250 percent difference in carbon footprint. More surprisingly, across a range of manufacturers and product formulations, the difference between Product A and Product B can be over 500 percent. Clearly, with this variation in performance it‘s critical to take a closer look at what is being used, to understand the impact of typical ‘go to’ products, and work to make sure the smartest option is being selected.

For a product category like carpet tile, even within a single manufacturer’s offering, one product can have a carbon footprint that is two and a half times greater than another. Across a range of manufacturers and product formulations, Product A may have a carbon footprint that is nearly five times greater than Product B. Source: The International EPD (Environmental Product Declaration) System. Chart created by Midori Sakurai of Gensler's Tokyo office.

Related Topics: