How To Control Water Costs Without Energy Penalties

Part 2 of a 2 part article on water efficiency best practices for cooling towers.

The foremost objective should be to control rising water and wastewater costs without incurring unacceptable energy penalties. In other words, don’t just trade energy efficiency for water efficiency. Many opportunities exist to accomplish this double task. The first and most obvious is to ensure that water leaks and building envelope air leaks are controlled and all equipment is properly maintained. Beyond proper maintenance, the options fall into four categories:

• Achieve more efficient cooling tower operation.

• Reduce the heat load on the cooling tower.

• Choose alternative methods of heat rejection that do not depend solely on water evaporation.

• Consider alternative technologies for cooling.

The cost, labor intensity, and related factors must be weighed when making choices on which options to use in your situation.

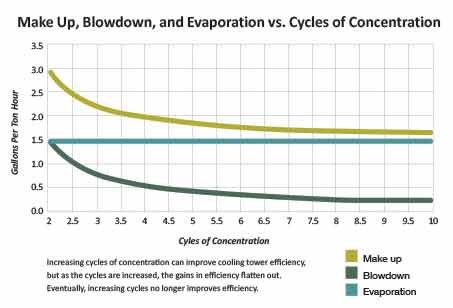

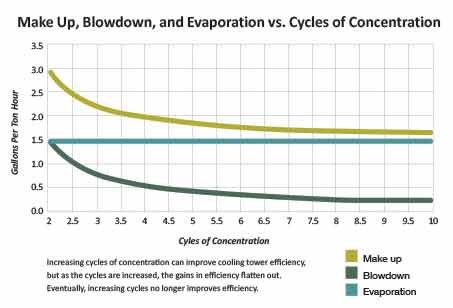

More efficient cooling tower operations have been a mainstay of the water efficiency community for decades. The most current effort is aimed at increasing the cycles of concentration for water in the cooling tower. But this has its limits, as shown in the “Make Up, Blowdown, and Evaporation” graph below. Based on the latent heat of evaporation for water, 1 ton of cooling (12,000 BTUs) is equal to 1.48 gallons of evaporation. For an evaporative process, this is the limit of water reduction even at near infinite cycles of concentration, but evaporation remains the same. Reclaimed wastewater and other alternate sources of water can be used, but these are still sources of water that would otherwise be returned to a watercourse — fresh water is water. The other two methods offer some unique and interesting possibilities.

Increasing cycles of concentration can improve cooling tower efficiency, but as the cycles are increased, the gains in efficiency flatten out.

Eventually, increasing cycles no longer improves efficiency.

Reducing heat load to the cooling tower is the first option. This can take several forms, including:

• The capture of the heat in the working fluid as it exits the compressor for water heating.

• Increasing building energy efficiency to reduce heat load on the air conditioning system (a BTU saved is a BTU that the air conditioning system does not have to remove and send to the cooling tower to be rejected by evaporation).

• The use of air-side economizers to achieve free cooling when outside temperatures permit.

• The use of water-side economizers. (Note that water is still evaporated, but the compressor heat that would normally be rejected to the cooling tower is eliminated. Air-side economizers are much less water-use-intensive.)

• Increased efficiency of HVAC equipment.

All of these forms have the impact of reducing the total number of BTUs the air conditioning system rejects to the cooling tower, and reduced heat load translates directly into water savings. For every ton hour not rejected to the cooling tower, 2 gallons of makeup water, 1.48 gallons of evaporation loss, and 0.5 gallons of blowdown are eliminated. For an office building with 800 tons of air conditioning and an energy efficiency of 0.65 kWh/ton hour, on a hot summer day when the total system daily load equals 65 percent of system capacity (24-hour basis), this translates to a makeup rate of about 30,000 gallons per day.

Alternative methods of heat rejection can either reduce the percent of the heat load rejected by evaporation of water or eliminate water use entirely.

Choosing which technology makes sense for your operation should include examination of both current and future utility rates — water, sewer, water treatment, electricity, natural gas, etc. Each has its advantages and drawbacks.

• Air cooling: This eliminates water use, is the simplest of all of the options to operate, and has low initial capital cost, but is less energy efficient. You will be trading energy use for water use, but for smaller systems under 400 tons, this is a real option to look at when the associated labor, water treatment, and related costs of operation of a cooling tower are considered.

• Hybrid cooling towers: Cooling tower manufacturers offer a number of variations on hybrid cooling towers. All have the ability to reject part of the heat load to the air and part to the water. These systems reduce water use and are being more closely looked at. Initial capital costs are higher than their simple air-cooled and cooling tower options, but energy efficiency is maintained and water consumption is reduced, potentially significantly.

• Geothermal systems: These systems use the ground as both a heat sink and source. They offer the ability to eliminate the need for either air cooling or cooling towers while not sacrificing energy efficiency. Their application, however, is limited to sites with adequate land, capital availability, and ground temperature, and thus geography is a consideration. Some systems can employ geothermal cooling as well as partial cool load dissipation with either air or cooling tower use.

• Sanitary sewers: One method being experimented with in Sweden and Switzerland is use of specially designed large wastewater pipes with heat exchangers built into the wall of the bottom of the pipe. It will be a while before the jury comes in on this one, but it shows the innovative thinking going on.

Alternative technologies for cooling include the use of combined heat and power systems that use the waste heat to operate desiccant systems. In humid areas, as much as a third of the air conditioning load is for removal of moisture. The use of desiccant systems removes this heat load from the mechanical compressor equipment and thus removes that heat load from the cooling tower.

By contrast, absorptive cooling with ammonia or lithium bromide is another technology that has been considered with cogeneration, but the heat rejected to the cooling system (heat sink) is actually higher per ton hour than with mechanical systems. This means that these technologies can actually increase water use if a cooling tower is used.

Rapidly rising water and wastewater costs are impacting all aspects of how we use water in our facilities. This is especially true for cooling technologies. Cooling towers have served us well, but we need to rethink how we use them and be aware of the alternatives discussed here, which can reduce both energy and water use. Each situation is unique, so the technology one chooses for a facility will vary, but in making that decision, both the present and future cost of energy, water, wastewater, labor, and liability must be taken into account. It is not just the cost of operation today that matters, but where these costs (energy, water, wastewater, labor, etc.) are trending in the future.

Bill Hoffman is president of H.W. (Bill) Hoffman & Associates, LLC, and has more than 40 years of water conservation and water resource planning experience. He has been involved in the development of water conservation legislation, water efficient codes and standards for IAPMO and ASHRAE, and new rating tools for both LEED and Green Globes. He can be reached at billhoffmantx@earthlink.net.

Email questions to edward.sullivan@tradepress.com.

Related Topics: