As Water Rates Rise, Efficiency More Important, Especially For Cooling Towers

Part 1 of a 2 part article on water efficiency best practices for cooling towers.

Water and wastewater costs have risen at a phenomenal rate over the last six years. According to a 2015 report by Circle of Blue, a group of scientists and journalists, rates nationally were up 41 percent since 2010. At the same time, the cost of electricity has stabilized, and in some areas actually decreased slightly. In the past, conventional chilled water/cooling tower air conditioning was the norm for large facilities. With all the new concern with Legionella, the concern over future water supplies in much of the nation, and the push for high-performance facilities, some are relooking at water use for air conditioning cooling systems. In response, the industry is changing and evolving to become both more energy- and water-efficient. For facility managers, understanding these trends, as well as the energy/water nexus of large commercial air conditioning systems, is critical to saving money and truly moving toward high-performance and sustainability.

Twenty years ago, the choices that large facilities had for air conditioning were simply air-cooled or water-cooled systems. With facilities of 200,000 square feet or more, the clear choice was either a two- or four-pipe system with a cooling tower. The chiller/cooling tower/chilled water system was the workhorse. The energy efficiencies available with these systems versus direct expansion/air cooled systems made them the clear choice.

But these systems use significant volumes of water. Recent compilation of data from all across the nation shows that in a typical office building, the cooling towers can account for a third to over half of all the water use for that facility. While this type of system will continue to be a workhorse for the foreseeable future, the rapid rise in water and wastewater costs and water scarcity issues are causing many to look for new strategies.

There are three factors that will impact both design and systems choices in the future. These three trends are: the rising cost of water and wastewater, new technologies, and the need to be both energy and water efficient.

Energy / Water Nexus

Regarding energy efficiency, new chillers with magnetic bearings and water-cooled variable refrigerant flow (VRF) systems have ushered in a new area of efficiency, but when fan, pump, and compressor energy are added together, the whole system efficiencies are in the 0.55 to 0.75 kilowatt hours (kWh) per ton hour range. Air-cooled direct expansion systems approach 0.95 kWh/ton hour, and air-cooled VRF (when IEER is approximate to kWh/ton hour) can operate in the range of 0.85 kWh/ton hour. So energy savings with water-cooled systems are in the range of 0.15 to 0.4 kWh/ton hour. In today’s electricity market, this energy savings from using a cooling tower equals a little over 1 cent to as much as 4.5 cents per ton hour of air-conditioning, depending on the system that a water-cooled system is compared to and where you are in the nation.

In the past, little attention was given to the water and sewer costs associated with cooling tower operations. But things are changing. While electricity prices are stabilizing or even declining in some markets, water and wastewater costs continue to inflate at around 6 percent a year, with no end to this trend in sight. In fact, according to Circle of Blue, water and wastewater rates rose 41 percent in the nation’s 30 largest cities between 2010 and 2015. Currently, across the nation, combined commercial and sewer rates average $10 to $11 per thousand gallons used. This is equal to 1 to 1.1 cents per gallon. Aging infrastructure, limits to development of new water supplies, and increasing environmental and water quality regulations indicate that this trend of increasing water and wastewater costs will continue into the foreseeable future.

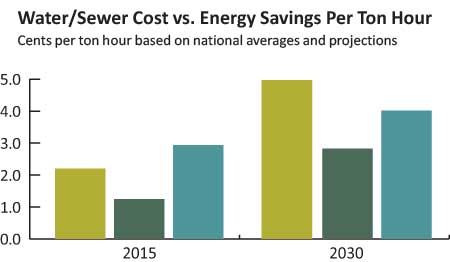

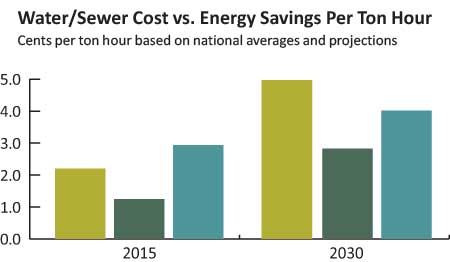

To put this into perspective for cooling towers, a tower operating at four cycles of concentration requires about 2 gallons of makeup water per ton hour of air conditioning, or about 1.9 to 2.2 cents of water and wastewater per ton hour. Even if evaporative credits are available, combined water and sewer costs are in the 1.25 to 1.75 cent per ton hour range. If inflation continues at 6 percent a year, the cost of water and wastewater will be in the range of 3 to 5 cents per ton hour.

Over the last 15 years, commercial electric rates have remained fairly constant or even decreased a little with cheaper natural gas. The U.S. Department of Energy currently projects that the cost of electricity will increase from its current national average of 9 to 10 cents per kilowatt hour to only around 12 to 14 cents per kilowatt hour over the next 15 years.

And then there are the costs of cooling tower water treatment, labor, Legionella prevention, and the liability involved in operating cooling towers. These additional costs can add another 0.1 cents to 0.5 cents per ton hour to the operating cost of a cooling tower, depending on the level of water treatment required.

This means that in the future, water and sewer costs may negate the energy savings that conventional technology relied on. The chart “Water/Sewer Cost vs. Energy Savings per Ton Hour” below summarizes the cost of water and wastewater versus energy savings in cents per ton hour. It uses a hypothetical example that factors in national energy, water, and sewer costs in 2015 with the inflation rates discussed above for just 15 years down the road. If these trends become reality, by 2030, about 15 years from now, water and wastewater will actually cost more than the energy saved with cooling towers.

So what does this portend? First, cooling towers have had and will continue to have a prominent place in the HVAC realm, but we also need to look at the options.

Based on current trends, by 2030, the overall cost of water and wastewater used for cooling towers could be greater than the cost of the energy saved by using cooling towers.

Related Topics: