« Return to FMDAA entries

Day Kimball Healthcare, Putnam, Conn.

CATEGORY: Sustainability

Day Kimball Healthcare, Putnam, Conn.

Overview

Day Kimball Hospital is located in rural Northeastern Connecticut. Our campus is a collection of buildings that were constructed between 1900 and 1998 and we have the same challenges that small community hospitals are facing today — an aging infrastructure and limited financial resources. Like most hospitals our size, we feel fortunate to have any level of profitability at the end of the year. As such, many times our needs outstrip our funding capability. This is especially true as we strive to maintain and improve this aging infrastructure with limited capital resources. But again, like other small not-for-profit hospitals, we have to be creative in identifying critical funding sources in order to achieve necessary improvements. Our story here is really about the perseverance and ingenuity of our Facilities Director and the extraordinary work he has done over the many years he has worked for our organization.

PROJECT #1: In 2000, the hospital initiated a comprehensive energy conservation project across virtually all areas of the hospital as follows:

- Installed sensors to control 1400 lighting fixtures

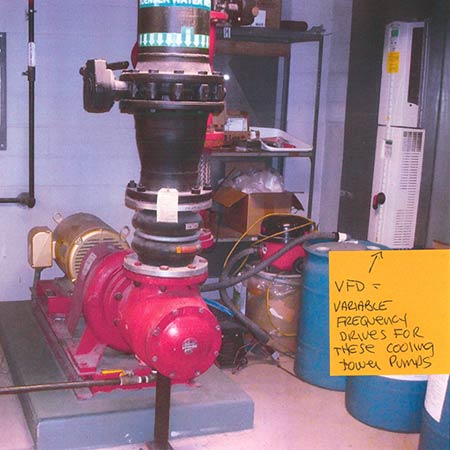

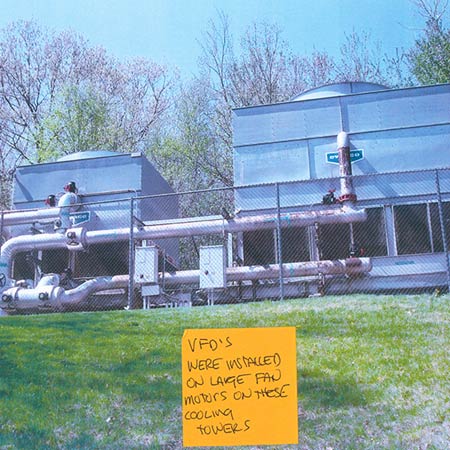

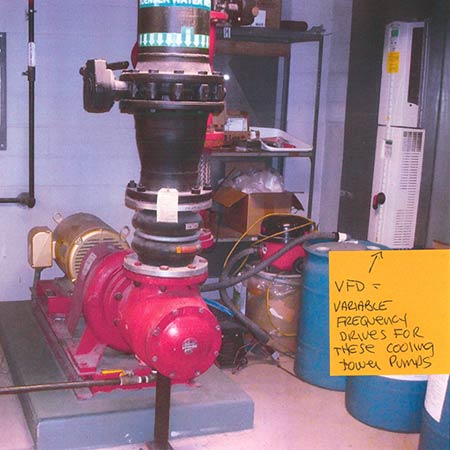

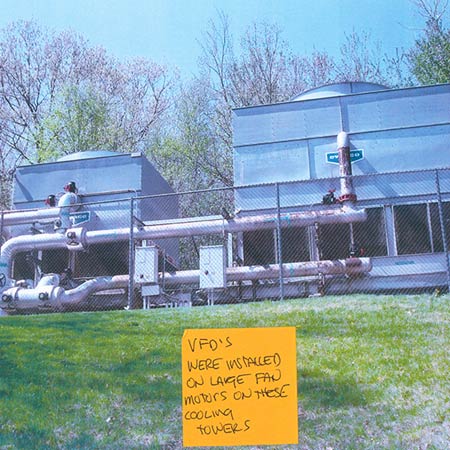

- Installed variable frequency drives on motors

- Converted air handling systems from constant volume to variable volume

- Replaced window air conditioners

- Installed kitchen make-up air units

- Installed heat recovery systems

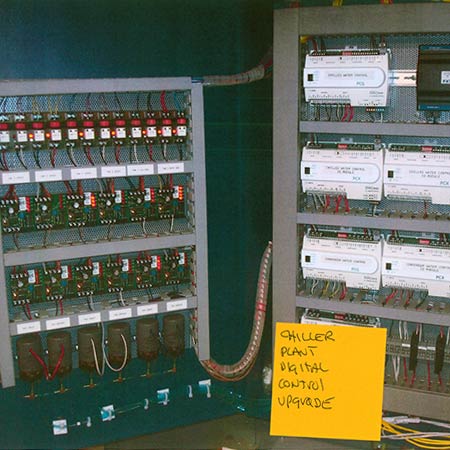

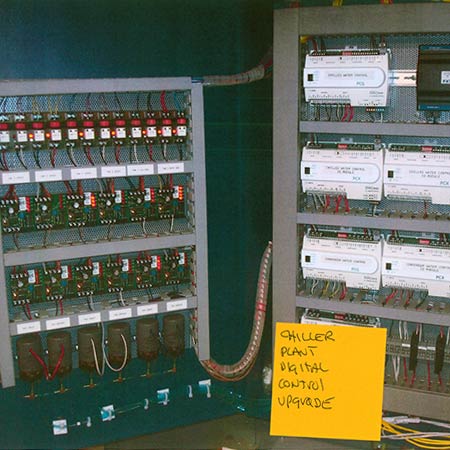

- Installed direct digital control systems

COST OF PROJECT: $1,000,000

FUNDING SOURCES: Utilized a $250,000 utility company incentive, a $500,000 no-interest loan from the utility, $250,000 equity contribution

ANNUAL SAVINGS: $240,000

RETURN ON INVESTMENT OF EQUITY: 3.125 YEARS

PROJECTED COST AVOIDANCE OVER LIFE: 10 YEARS/$2,400,000

PROJECT #2: In 2006 we initiated an off-campus electrical conservation project.

- Retrofitted off-campus lighting fixtures and controls.

COST OF PROJECT: $122,000

FUNDING SOURCES: $61,000 incentive from the utility and a $61,000 equity contribution.

ANNUAL SAVINGS: $24,000.

RETURN ON INVESTMENT OF EQUITY: 2.5 years

COST AVOIDANCE OVER LIFE: 10 YEARS / $240,000.

PROJECT #3: PHASE I: 2013 / 2014 GAS & ELECTRICAL CONSERVATION. This project included the following measures:

- Install new high performance exterior lighting

- Add variable frequency drives to the cooling tower and condenser water pumps of the chiller plant

- Replace $83,000 in antiquated controls to optimize chiller plant efficiency.

- Replace and add controls to steam plant to enable pressure reset on a scheduled basis.

COST OF PROJECT: $423,839

FUNDING SOURCES: Utility Incentives totaling $211,919

Equity contribution totaling $211,919.

ANNUAL SAVINGS: TOTAL ANNUAL IS $71,908

Natural Gas Savings is calculated to be $33,296

Electric Cost Savings is estimated at $38,612 per year

RETURN ON INVESTMENT OF EQUITY: 2.95 years

COST AVOIDANCE OVER LIFE: 15 YEARS / $1,078,627.

Greg Harubin and his team in facilities have done a remarkable job in moving our updating critical systems at a total cost of $1,022,919 with an impact that allowed us significant energy savings and cost avoidance totaling $3,718,627 over the expected life of these projects while keeping our investment in these projects within our financial capacity. This equals a payback of $3.63 for every dollar spent – a great achievement!

In-house Participants

Greg Harubin, Director Facilities

Tim Morin - Supervisor

Bob Andrews - Project Manager

Additional Information

» View Boiler Steam Pressure Reset (PDF)

↑ Back to top