« Return to FMDAA entries

Max Planck Florida Institute for Neuroscience

CATEGORY: Sustainability

Overview

The Max Planck Florida Institute (MPFI) is the first institute outside of Europe for Germany’s Max Planck Society.

The MPFI facility located in Jupiter, Fla., operates 24 hours per day, 7 days a week, is a 109,960 gross square foot building with three floors plus mechanical penthouse equipment space.

Dedicated to research/laboratories, the space is designed to accommodate wet and dry bench research, instrumentation labs, computational research, core imaging facilities and microscope suites, information technology services and offices for researchers and support staff. In addition, there is space designated for core laboratory support services including the Animal Resource Center, Electron Microscopy, Optical Workshop, Molecular Core, Mechanical workshop and Central Glass wash/Sterilization area.

Designed to reduce energy consumption and use materials wisely, MPFI set a high standard for sustainable laboratory design in South Florida, consuming the least amount of energy possible, which resulted in achieving the U.S. Green Building Council’s LEED-NC Gold Certification.

Some of the features that contributed to the Gold certification include: an air-conditioning zoning strategy that reduces demand load within the space, mechanical systems with state-of-the-art energy recovery wheels to capture useable energy from building exhaust.

Another feature is the recycling of moisture (condensate) removed in the process of dehumidification that contributes to the building’s cooling system. It was the recognition of this feature underutilization that presented an opportunity to improve the sustainability function, lower utility water use and provide direct cost saving.

HVAC: MPFI building design includes a combination of Constant Air Volume (CAV) and Variable Air Volume (VAV) air terminal boxes. A constant volume unit will continuously supply air to a zone/room constantly at the scheduled airflow rate. A variable volume terminal unit will supply air between a minimum and maximum scheduled airflow rate.

100% of the supply air in the building is carried in through the Air Handling system from the Outside. Conversely all interior spaces are 100% exhaust to the exterior through rooftop exhaust fans.

The conditioned air from the central air handling unit is set to produce 55 degree air to remove humidity and then distributed through the building to local CAV or VAV valve boxes. This air is then reheated via a hydronic (hot water) coil attached to the outlet of the constant volume or variable volume terminal unit to meet desired space temperatures.

The chilled water (CHW) system consists of a variable primary pumping loop for two (2) chillers that distribute water to the facility AHU cooling coils. The primary loop contains 950 tons of connected cooling capacity with two (2) 475 nominal water cooled variable speed drive chillers. The chillers have associated matching cooling towers and three (3) condenser water pumps.

The variable chilled water pumping consists of three (3) pumps each with a variable frequency drive. Each pumping system has a spare pump providing N+1 redundancy.

The HVAC system is monitored and controlled by a Siemens Building Automation System (BAS). The BAS communicates through BACnet protocol to several integrated devices that contain their own control logic and microprocessor. In addition to the control points provided by Siemens, key monitoring points are displayed at the user workstation from the integrated equipment.

Through the use of smart technology the HVAC systems can monitored, set, adjusted, altered, and restarted via remote access login by the Facilities staff.

What problem or opportunity started the process that produced the achievement?

The original design calls for condensate from the AHU’s to return to a 200 gallon storage tank. The sequence of operations was: on demand from the cooling tower and indication the condensate tank is full the condensate collection pump engages and delivers water directly to the cooling towers.

The issues identified by the facilities team include a poor pipe arrangement on the storage tank and the limitations presented by the designated sequence of operations caused up to 85% of collected condensate to be unused and sent to city sewer in lieu of cooling towers as intended.

Why did you choose a particular course of action?

It was recognized that the desire is to increase the capture of condensate water and in conjunction increase the tower cycle ration. This course of action presented critical issues regarding the chemical water mixture of domestic city make up, condensate return and the new requirement to add a water softener system to achieve this goal.

What challenges did you face along the way, and how did you overcome them?

One of the first challenges was to identify a contractor with the expertise to assist in this endeavor in a hot/humid climate while recognizing the negative effect that could damage the HVAC equipment if the correct water mixture is not maintained:

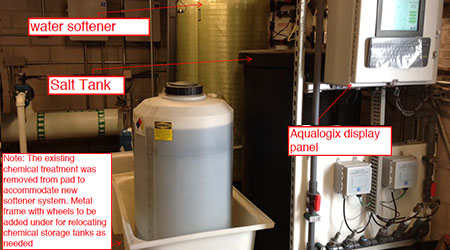

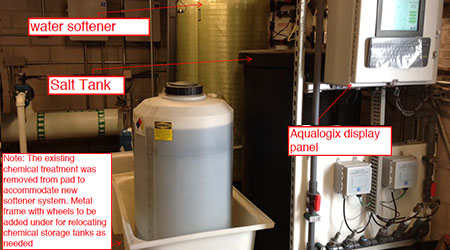

- Due diligence was taken by the Facilities Management team to seek out viable contractors and vendors that had the expertise and experience to meet project goals. This was accomplished both formally via bid proposals and informally via equivalent industry networking contacts. Ultimately Aqualogix was selected for their expertise and unique monitoring and management capabilities.

- Funding on a non-planned project. This opportunity was identified and proposed during the year when budgets were already in place. While this could have been submitted with annual budget cycle review , a proposal was presented to the Senior leadership team identify the advantages of this scope and project cost benefit along with the projected the ROI of 24-30 months.

- Coordination of existing team to buy in to project.

- The existing support vendors; equipment manufacturers, water treatment vendor, building automation system, were all engaged early in the process. It was imperative to relay the purpose and scope of the project and their role in the process. It was particularly important to reassure each organization that this new project was to to existing operation, not replace any functional piece. Each team member was given the opportunity to review the intent, process and expected results and provide feedback on their particular piece of the puzzle.

What was the outcome of the process, i.e., the achievement?

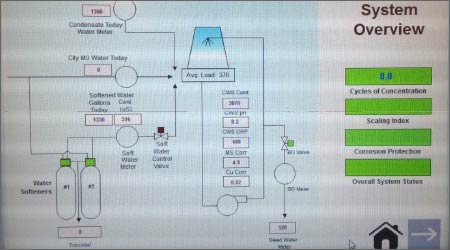

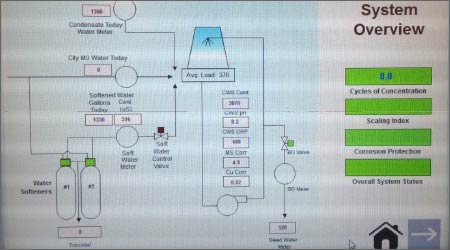

This has exceeded all expectations set at the start of the project. As of 1/1/16, MPFI now sends 100% condensate return back to the cooling towers. The chemical water treatment and water softener system mixture has been adjusted to accommodate the revised water content and the tower cycles has been increased from 4:1 to 9:1 thus decreasing the blowdown ratios.

The water softener system in place is unique via a head end monitoring system managed by Aqualogix. This system continuously monitors the chemical makeup of the tower source water and ensures that these critical mixtures are maintained at all times. Equally important is the ability to provide remote notification to MPFI facilities in the event of an unforeseen system component failure.

MPFI has experienced an instant reduction in overall water usage of almost 23% from the average prior use in the corresponding months.

In-house Participants

David Hader: Head of Facilities

Corey Pine: Facility Manager

Fausto dos Santos: HVAC lead

John Schirmer: Electrician

Mike Mitchell : Plumber

Additional Information

» View Energy Savings (PDF)

↑ Back to top