Inspection, Testing, Maintenance: How to Keep Fire Safety Systems Safe

While fire safety systems are generally dependable, they do require ongoing attention if they are to perform as designed in an emergency.

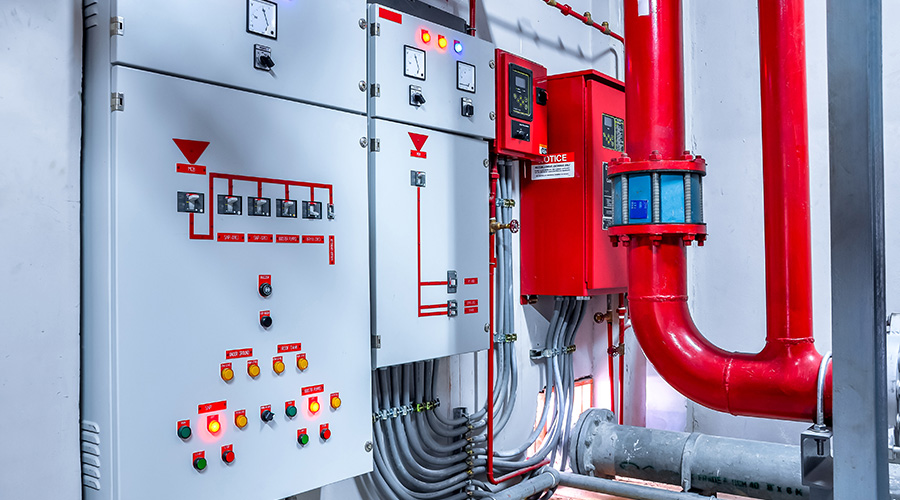

Maintenance and engineering managers and occupants all depend on the facility’s fire and life safety systems to keep the people, property and contents safe. These systems, while very dependable, require ongoing attention if they are to perform as designed in the event of an emergency.

Postmortems on systems that have failed to operate properly during an emergency typically point to lack of attention and maintenance — alarms that have been silenced, smoke detectors that are clogged with dirt and even something as simple as failing to reopen a valve after working on the system. All are simple but potentially deadly mistakes that managers can avoid through proper maintenance procedures.

NFPA 72, the National Fire Alarm and Signaling Code, spells out what managers must do in terms of inspection and testing to ensure their systems are functioning properly and are in compliance. System manufacturers typically have a checklist of tasks system owners are expected to do and the frequency with which they must do it.

Local codes and the authority having jurisdiction (AHJ) might have additional requirements. But in all cases, managers should consider requirements from NFPA 72, system manufacturer recommendations, and AHJ requirements to be the minimum level of compliance. The particular characteristics of the facility and its fire and life safety needs also might require additional activities.

Information presented here is just an overview of some of the important inspection, testing and maintenance activities system owners must perform on fire and life safety systems. For more detailed information, consult NFPA 72.

The three basic parts of any program designed to keep fire and life safety systems operating properly are inspection, testing and maintenance.

Inspections

Inspecting the operation of a fire and life safety system that appears to be operating normally typically is not high on any front-line technician’s to do list. But like all building systems, these systems deteriorate over time. Batteries fail. Components corrode. Indicator lights burn out. Dirt accumulates in smoke detectors and sprinkler heads. Performing regularly scheduled inspections, conducting the required tests and keeping up with maintenance tasks are the only way to keep systems operating reliably.

Inspections also are critical in identifying where changes have been made to the facility and its operations — changes that might need modifications to the existing systems or installation of additional fire and life safety equipment.

New or modified systems

Inspections and tests must be performed by factory-trained and certified personnel for the type of system being tested — personnel employed by a nationally recognized and certified organization or by personnel registered or certified by the local authority.

The inspecting and testing program starts with the acceptance testing of all new system installations. NFPA 72 spells out the requirements that owners must adhere to in conducting those tests. Unfortunately, managers can be under a great deal of pressure to accept the system, since testing is basically the last step in the construction process. Contractors want to move on, and occupants want to move in. But before they can do so, the system must pass the acceptance test.

Acceptance testing for new systems includes verifying all fire alarm initiating devices and notification devices, including pull stations, smoke detectors, heat detectors and alarm notification devices. Interfaces with other building systems, such as elevators and HVAC equipment, also must be verified. Once completed, the inspector must complete a detailed sign-off report and provide it to the owner or manager before the space can be occupied.

When acceptance testing is complete, a complete inventory of all installed components, such as smoke detectors, pull stations and horns will be part of the final report. This inventory is essential in ensuring that all system components are properly inspected, tested and maintained over the system’s life. This inventory also serves as the basis for future inspections and tests.

When modifications are made to an existing system, the requirements are similar. According to NFPA 72, modifications include adding or removing any system component, modifying or repairing system hardware or wiring, or modifying or upgrading system software. Additionally, the inspector also must test 10 percent of initiating devices in the system up to a maximum of 50 devices. The inspector also must test any added components, wiring or software, as well as those that might be impacted by the changes.

When system modifications are completed, the inventory of installed components must be updated to reflect additions to the system, as well as components that have been removed.

Scheduled inspections

Once acceptance testing on the system is complete, managers must implement an ongoing inspection and testing program. Specific items must be inspected or tested weekly, monthly, semi-annually or annually. While specific inspection and testing activities depend on the type of system installed, some common activities exist.

Each week, technicians should check to see that central panels and other control equipment are in normal operating condition. This step includes a visual inspection of trouble lamps, system power lamps, fuses and building system interfaces, including elevator recall, sprinkler system activation, fire pumps, HVAC systems, smoke control systems, and kitchen hood suppression systems.

All system batteries must be visually inspected monthly for leaks and corrosion. Terminals must be inspected for tightness and corrosion, and additional inspections, including load testing, must be performed for certain types of batteries.

Depending on the type of battery installed in the system, semi-annual inspections and tests include additional activities for batteries that function as secondary power sources for alarm systems, including load voltage tests, discharge tests, and specific gravity tests. Alarm transmission equipment that automatically notifies the fire department when the system goes into alarm must be visually inspected semi-annually.

Annual inspections and tests

The entire fire alarm system must be inspected and tested once each year. Tests are to include all central control equipment, remote annunciators, initiating devices, alarm notification devices, and all interfaces with other building equipment. Batteries and battery chargers must be inspected and tested.

Smoke detectors have their own testing requirements. Battery powered detectors must have their batteries replaced annually and must be tested for sensitivity as specified by the manufacturer. Hardwired smoke detectors must be tested one year after installation. After that, the test should be repeated in two years. If the detector is found to be within its manufacturer's specified sensitivity range after the first two year test, the period of time between tests can be extended to every five years.

The annual inspection goes just beyond the system's installed components. Those performing the inspection must look for changes within the facility that might impact the operation of the system, including changes to space configurations and occupancy. For example, newly installed equipment or furniture might obstruct the operation of devices such as smoke detectors or sprinklers. All such problems must be identified so necessary changes to the system can be implemented.

Maintenance

Weekly, monthly, semi-annual and annual inspections and tests identify issues within the system that need correction. While they are necessary and required steps, managers should consider them the minimum level of maintenance for the system. Components corrode, wear, and go out of calibration. Dust and dirt accumulate on components, such as smoke detectors, that could interfere with their operation.

Maintenance begins with a quick response to a failure within the system. When visual inspections or testing identify a fault, it is essential to make repairs as quickly as possible. Technicians should not make temporary repairs or bypasses of a fault on an emergency basis only. Follow-up with permanent repairs must not be delayed.

Maintenance requirements increase as the system ages. Components have a finite life span, even if they continue to pass inspection. Eventually, many components will have to be replaced if the system is to keep operating reliably. While portions of the system, such as sprinkler piping, have a long service life, most fire alarm systems have a rated system life of 15-25 years. Beyond that point, maintenance costs can increase dramatically. Managers also might have difficulty obtaining replacement parts or software upgrades because manufactures might no longer support that particular system.

Documentation

When a system passes the acceptance test, the inspector must turn over a number of documents to the owner or manager. Besides detailed results of the acceptance test, these documents must include:

• operator instruction manuals

• maintenance manuals that detail component maintenance tasks and frequencies

• detailed testing procedures broken out by required frequencies

• troubleshooting steps.

It is essential that managers document all activities related to inspection, testing and maintenance of the entire system. From the acceptance test to even the most minor repair, all of these activities must be logged and filed. While NFPA 72 requires that records be kept only until the next annual inspection, managers would be wise to retain all reports. By doing so, they can trace back through the data to track recurring issues and maintenance costs — important information when facing repair or replace decisions.

James Piper. P.E., is a national consultant based in Bowie, Md. He has more than 35 years of experience with facilities maintenance, engineering and management issues.

Related Topics: