How to Identify Common Fire Sprinkler Problems

Managers need to ensure buildings are regularly inspected and maintained in proper working order.

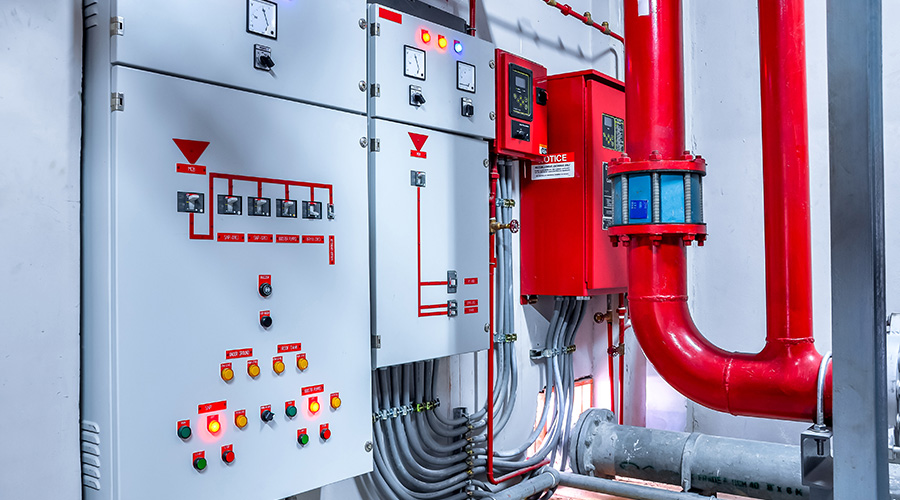

Automatic sprinkler systems play an important part in the safety of the occupants of institutional and commercial facilities. These systems are designed to limit the spread of a fire and contain it to the compartment of origin.

But in many facilities, problems can arise. If the sprinkler system has not been designed, installed and maintained properly, the fire can spread, increasing the risk of damage to the building and harm to occupants.

Looking for trouble

Sprinkler systems must be designed properly in accordance with the local building code and NFPA 13 Standard for the Installation of Sprinkler Systems. In addition to a properly designed sprinkler system, the sprinkler contractor must install the sprinkler system in accordance with the design. When the design changes or unforeseen interferences arise, the contractor and designer must come up with solutions that meet the code requirements.

Once a sprinkler system has been successfully installed, the responsibility of maintaining it falls to the building owner. According to the International Fire Code (IFC) 2015 Edition, 901.6 Inspection, Testing and Maintenance, the fire detection, alarm, and extinguishing systems, mechanical smoke exhaust systems, and smoke and heat vents must be maintained in an operative condition at all times and shall be replaced or repaired where defective.

The IFC goes on to require that NFPA 25 Standard for the Inspection, Testing and Maintenance of Water-Based Fire Protection Systems be used to keep an automatic sprinkler system in good working order.

As a fire protection engineer, I have participated in all phases of automatic sprinkler system design, installation, inspection, testing, and maintenance. While local jurisdictions require fire protection professionals to be involved in the design and installation process, this is enforced through the permitting process. The inspection, testing and maintenance typically is left to the building owner.

From my experience, this is where the process is most lacking. We regularly inspect buildings and identify many deficiencies with sprinkler systems. Although some issues are technical and require a fire protection professional to work through, many other problems can be identified by maintenance and engineering managers and front-line technicians.

Spotlight on violations

What should managers and their staff look for when it comes to fire sprinklers? To maintain buildings in the safest condition, managers need to ensure buildings are regularly inspected in accordance with NFPA 25 and maintained in proper working order.

During our inspections, we repeatedly see the problems listed below. The items are relatively easy to identify and should not cost much to repair.

NFPA 13, 2019 Edition, “10.2.5.3 Minimum Distances from Walls. Sprinklers shall be located a minimum of 4 inches from a wall.” This is required for all types of sprinklers — pendant, upright and sidewall. Sprinklers located closer than 4 inches to a wall might be subjected to cooler air and result in a delayed activation. We typically see this violation after a minor remodel where a partition was relocated and a fire protection professional was not brought in.

NFPA 13, 2019 Edition, “16.2.3.2 Where cover plates on concealed sprinklers have been painted by other than the sprinkler manufacturer, the cover plate shall be replaced.” In buildings or spaces that use concealed sprinkler heads, an aesthetically pleasing cover plate is used to conceal the sprinkler. The cover plates must be listed for use with the sprinkler to ensure proper activation and deployment of the sprinkler. The cover plate shall not be painted by anyone other than the manufacturer.

In many buildings we survey, cover plates have been painted over. In a time-saving effort, the contractor tried to paint around the cover plate but still got paint on it or painted the entire cover plate. Similar to a window that is painted shut, a small amount of paint can adhere the cover plate to the ceiling, resulting in delayed activation of the sprinkler head or possible obstruction of the spray when it is activated.

NFPA 13, 2019 Edition, “7.2.5.2 Painting. Sprinkler shall only be painted by the sprinkler manufacturer.” When sprinklers have been painted, whether accidentally or purposely by persons other than the manufacturer, it can cause delayed activation or malfunction. Once the sprinkler has been painted, it is not acceptable to use solvent or other means to remove the paint.

According to NFPA 13, 2019 Edition, “16.2.3.1 Where sprinklers have had paint applied by other than the sprinkler manufacturer, they shall be replaced with new listed sprinklers of the same characteristics, including K-factor, thermal response, and water distribution.” NFPA 25 Standard for the Inspection, Testing and Maintenance of Water Based Fire Protection Systems, 2017 Edition, Table A.3.3.7, notes that, “One sprinkler and less than 50 percent of sprinklers in compartment is heavily loaded or corroded; painted operating element, bulb, deflector, or cover plate” is a critical deficiency.

A critical deficiency is defined as “a deficiency that, if not corrected, can have a material effect on the ability of the fire protection system or unit to function as intended in a fire event.” Table A.3.3.7 notes that “Two or more sprinklers in compartment are heavily loaded or corroded; painted operating element, bulb, deflector, or cover plate” is an impairment. An impairment is defined as “a condition where a fire protection system or unit or portion thereof is out of order, and the condition can result in the fire protection system or unit not functioning in a fire event.”

NFPA 13, 2019 Edition, “16.2.5.4 The use of caulking or glue to seal the penetration or to affix the components of a recessed escutcheon or concealed cover plate shall not be permitted.” This issue can be difficult to detect because the glue or caulk is not always visible. But once a technician has seen it on one sprinkler, he or she can look closely at others to see if the problem is widespread.

The problem with gluing or caulking the recessed escutcheon or concealed cover plate to the ceiling is that this step violates the manufacturer’s instructions. For the concealed head cover plate, the glue or caulk will block the heat from getting to the head, and if the head does activate, then the cover plate can block the spray pattern and delivery of water to the fire.

NFPA 25, 2017 Edition, “5.2.1.1.5 Escutcheons and cover plates for recessed, flush, and concealed sprinklers shall be replaced with their listed escutcheon or cover plate if found missing during the inspection.” During our inspections, we frequently see missing escutcheon or cover plates. The escutcheon and cover plates are part of the listed sprinkler assembly and are required. This situation is a concern because hot gases from a fire can escape into the space above the ceiling.

NFPA 25 lists this as a noncritical deficiency because the activation time of the sprinkler should not be impacted. A noncritical deficiency is defined as “a deficiency that does not have a material effect on the ability of the fire protection system or unit to function in a fire event, but correction is needed to meet the requirements of this standard or for the proper inspection, testing, and maintenance of the system or unit.”

Rock Meng is the president of Capitol FPE, a life safety and fire protection consulting company. He is a registered fire protection engineer in five states and has more than 20 years of experience in fire alarm design and installation.

Related Topics: