Managing Knowledge Gaps Within Facilities Management

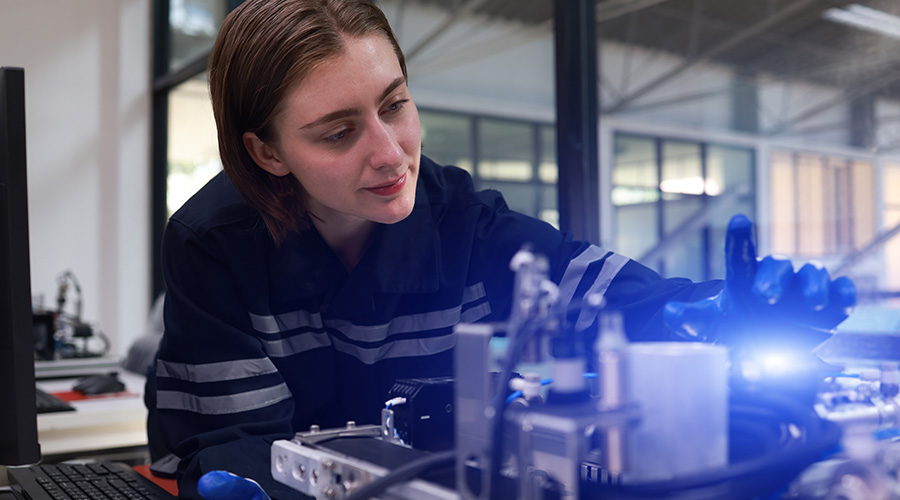

As managers search for technicians to fill positions vacated by retiring workers, many are just grateful to find new hires with at least some experience.

By Dan Hounsell, Senior Editor

What, exactly, do your front-line technicians know? The question is more important than it might seem at first glance.

As maintenance and engineering managers continue searching for technicians to fill positions vacated by retiring workers, many are just grateful to find new hires with at least some relevant training and experience. But even as they make progress in hiring, facilities and all their complex operations, equipment and technology will continue to test managers and their staffs on every shift of every day.

I included “shift” purposely after a recent conversation about the growing need for resilience in facilities. Departments can’t afford to just keep up with daily maintenance challenges. They also must help facilities prepare for and return to operation after wildfires, floods and hurricanes, all of which are becoming more frequent and destructive.

The mounting pressure should prompt managers to look more closely at their technicians’ skills — and more importantly, the gaps in those skills. I was talking about resilience and training with John Friedlander, associate managing director for security risk management with Kroll. He pointed out an often-overlooked gap in maintenance technician training.

“Where we find gaps is in third-shift training and awareness,” Friedlander says. “Often, they are either overlooked or out of the training cycle because of the nature of third shift. They might know the building better than anyone else, but they have not been informed of what to do in the incident — a smoke event or heated air or fire and proper notification protocols — whether it's the pull station on the wall next to the exit door or summoning assistance.

“In 2022, no facility is overstaffed. They are lean operations, and it's hard to find time for after-hours training, planning and preparedness.”

Managers would be smart to identify and address such shortcomings because the next equipment breakdown or actual emergency will certainly find the gaps.

Related Topics: