Data, Trust Building High-Performance Facilities Teams

Hard work and relentless precision are the MO for Brendan Robinson and his facilities team at Under Armour.

“It’s what you do in the dark, that puts you in the light. Rule yourself.” That’s the tagline for one of Under Armour’s viral ad campaigns. On screen, famous athletes exude single-minded determination as they push through the practice, practice, practice required to achieve greatness. Glory on game day is won through hard work and relentless precision behind the scenes. That message is not just a branding strategy for the performance-apparel manufacturer. It permeates the culture of the entire company, right down to the facilities team led by Brendan Robinson, director of facilities and operations, corporate real estate.

Robinson has set about better aligning the facilities team to the larger organizational goals at Under Armour with an eye on achieving high performance. He has been methodical in honing his team, starting by listening and observing to get a clear understanding of the processes in place, then judiciously applying technology solutions, gathering data and feedback, and going back to tweak the practice as needed. Repetition, precision, relentlessness. Under Armour’s first television commercial had the slogan, “Protect this house.” Robinson, it seems, is wholly intent on doing just that.

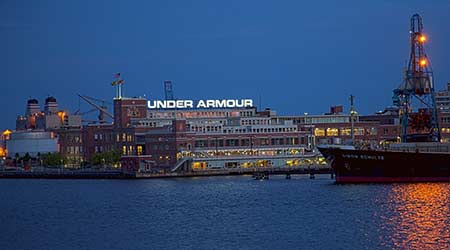

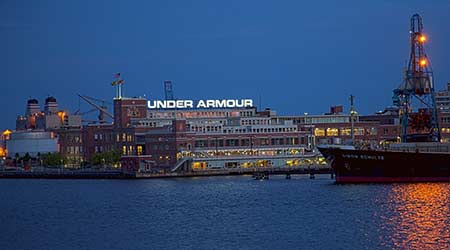

Now just over two decades into operations, Under Armour’s team is set to outgrow its existing Global Headquarters campus at Tide Point, Baltimore, Md. The multi-building Tide Point headquarters campus includes facilities such as a state-of-the art 35,000-square-foot gym, a café, product showrooms, research and development labs, as well as office facilities. The headquarters buildings used to be Procter & Gamble soap factories, built in the 1920s, and bear names like Joy, Cheer, and Cascade. In 2015, Under Armour started the process of expanding into their new Port Covington campus on 55 acres in Baltimore. That site now has a 170,000-square-foot office building which is an adaptive reuse of a former Sam’s Club. Port Covington is also the home to Under Armour’s manufacturing and design innovation facility called Lighthouse. Future expansion plans at Port Covington include a new up to 4 million-square-foot headquarters campus. According to the company’s website, the corporate vision of the campus is that it is to be a place of “relentless growth and innovation.”

(The buildings at Under Armour’s existing global headquarters campus at Tide Point in Baltimore, Md., go by names like Cheer and Joy as a nod to the soap products once manufactured in them.)

Start by listening

“We evolve almost daily here at Under Armour,” says Amy Larkin, vice president of culture at Under Armour. Business units are constantly hiring new people as the company grows, which drives a certain amount of change from the facilities standpoint, from both day-to-day moves and larger business unit realignment. There’s also the larger ongoing capital redevelopment process on the Tide Point campus, which includes things like new windows and new furniture standards. The company is three-quarters Millennial, and so there is a lot of focus on changing the workplace environment to better suit the needs of that demographic. “We’re a big growing company and there’s a lot going on,” says Robinson.

When Robinson joined the team a little over three years ago, there was nothing wrong, per se, about how the facilities team was doing their work. But he saw there was an opportunity to embrace the company’s culture of continuous improvement and apply that to the operations strategy. “When I came here I talked to people and I asked them about their jobs and I asked them to tell me about themselves and what they do,” Robinson says. What he heard was focused on reactive task-oriented work. Adjust the temperature if someone requests it. Fix something if it breaks.

“They didn’t naturally speak in terms of how the things that they do are important and the impact they have to the overall organization and meeting the mission,” Robinson says. “And so I instantly wanted to help them find those words.” He wanted them to be able to understand how the work they do affects others in the organization, and what that really means to productivity in the overall organization. He sees his role as focused on creating a high performance team — both writ small with his own crew and as it extends to Under Armour as a whole. With a relatively young team and a swiftly growing organization, Robinson also needed to find a way to improve on-boarding on the facility management team to shorten the time from hired to effective teammate.

Data-driven performance

One tool Robinson created with his team to solidify their sense of mission is the facilities and operations “logic model.” Through a series of workshops with his team, Robinson had them answer the following question: If the mission of Under Armour is to “make all athletes better through passion, design, and relentless pursuit of innovation,” how does facilities and operations support that mission? The team spelled out all the services the facilities and operations staff provides and discussed how they could drive organizational value with their work. Answers included optimizing facility costs and ensuring the built environment supports business needs. But they also included delivering “amazing experiences” to potential clients and teammates, and providing world-class amenities.

Once he had the process fully mapped out of what facilities and operations was currently doing and where they were headed, Robinson set about applying technology solutions to support the change he wanted to see. “You have to assess your policies and procedures, and then you have to look at the technology that you have in place that’s supporting you,” Robinson says. “Once you have that north star of what you do that’s important that adds value, you then need to align all those other things.” The team translated the logic model into a new IWMS software platform, which helped them to get the data on their processes needed to push towards high performance. “We can track the progress of things,” Robinson says. “It creates that data so that we can know if we’re meeting our service level agreement times or performing within KPIs.”

The software gave visibility into things like work order requests by type and building, and which teammates were completing what percentage of work orders on time. Another tool Robinson makes heavy use of is customer surveys of workplace satisfaction and food service. And he is getting results. “Brendan has been able to come in and make an impact almost immediately,” says Larkin. For example, satisfaction with the workplace went from 2.9 to a 3.7 on a 1 to 5 scale between 2014 and 2016.

Related Topics: